Edible fungus liquid strain incubator with controllable temperature and humidity

A technology of liquid strains and edible fungi, which is applied in the direction of sterilization methods, biological material sampling methods, methods of supporting/immobilizing microorganisms, etc., and can solve problems such as the influence of strain cultivation, cumbersome production process, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

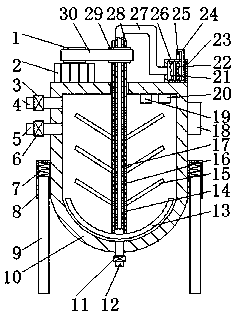

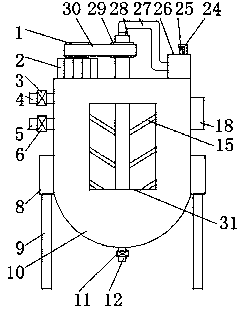

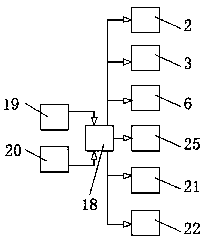

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0017] refer to Figure 1-3 , a kind of temperature-humidity-controllable edible fungus liquid incubator, comprising a box body 10, three guide columns 8 are installed at equal intervals on the outer lower part of the box body 10, and support legs 9 are inserted in the inside of the guide column 8 to support The upper end of leg 9 is connected with spring 7, and spring 7 is positioned at the inside of guide column 8, can play the effect of cushioning and shock absorption, improves use effect.

[0018] A rectangular hole is arranged in the middle of one side of the box body 10, and an observation window 31 is installed inside the rectangular hole to facilitate observa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com