Pervious concrete and construction method thereof

A technology of permeable concrete and construction methods, which can be applied to other household appliances, coagulating pavements paved on site, and applications, which can solve the problems of unfavorable polypropylene fiber uniform dispersion, polypropylene fiber is not easy to combine, and reduce the reinforcement efficiency of polypropylene fiber And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

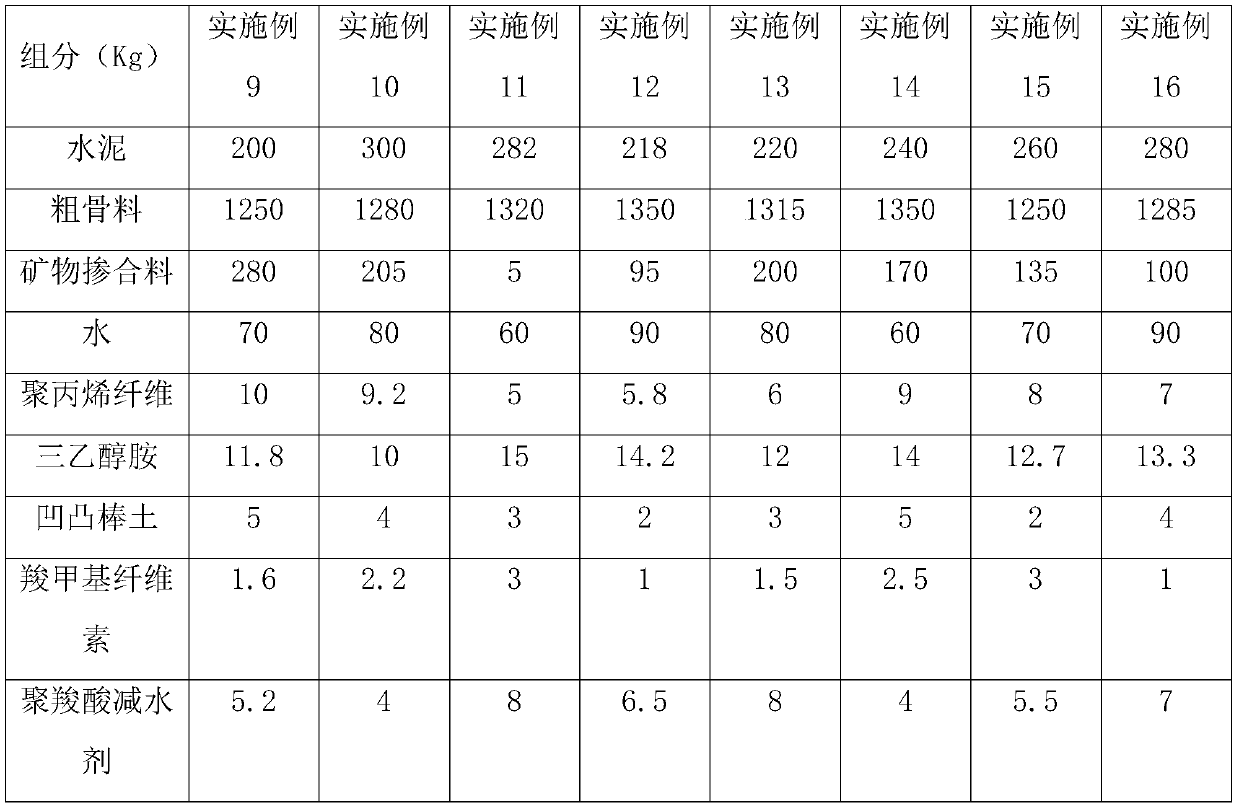

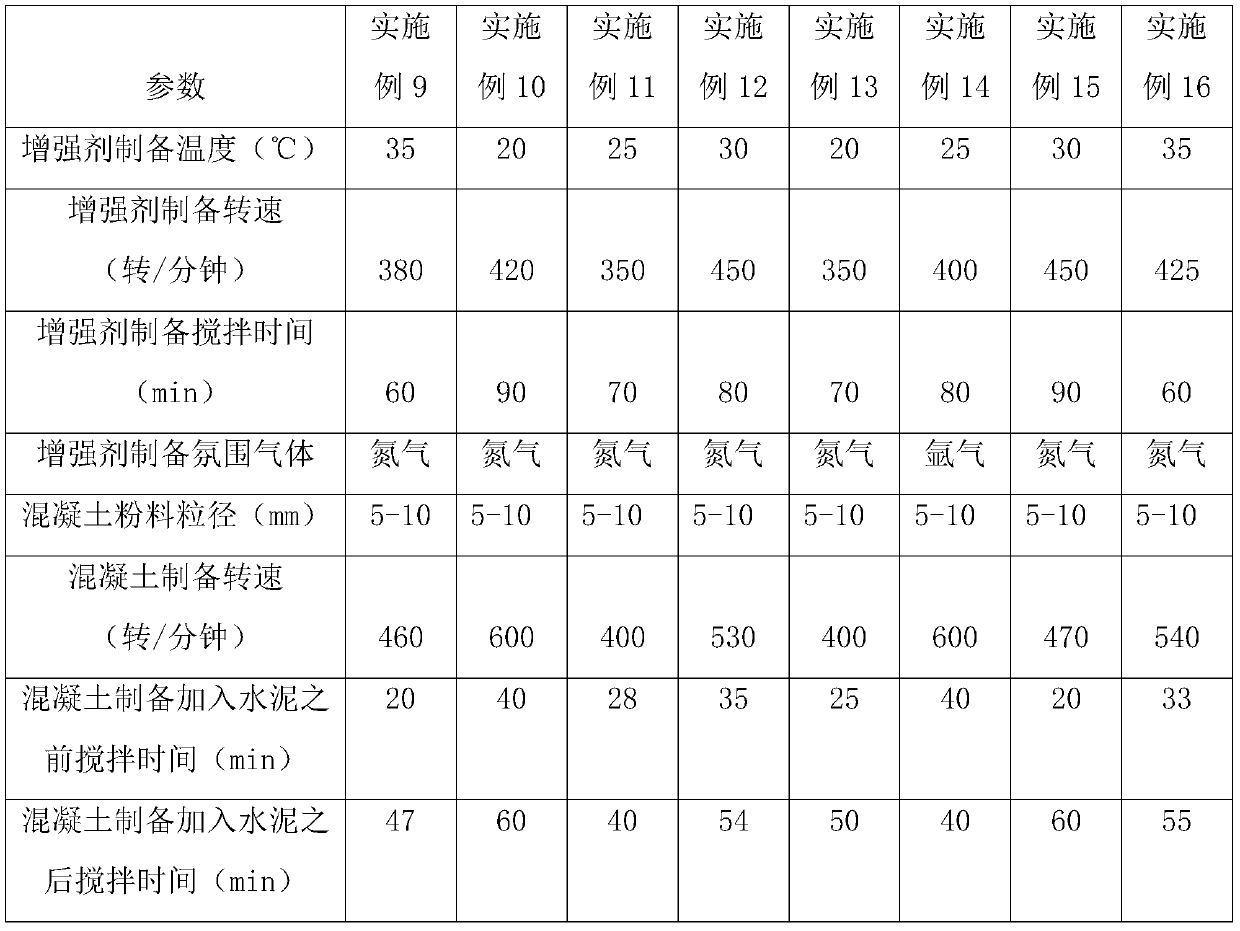

Examples

Embodiment 1

[0034] Embodiment 1: a kind of construction method of pervious concrete, comprises the steps:

[0035] (1) Preparation of reinforcing agent: Weigh 7.5Kg polypropylene fiber, 13Kg triethanolamine, 3.5Kg attapulgite, 2Kg carboxymethyl cellulose, stir at 400 rpm for 75min at 28°C under nitrogen atmosphere, turn Put into packing bottle and seal, make surface enhancer;

[0036] (2) Mixing: take by weighing 1300Kg coarse aggregate and 150Kg mineral admixture, mix evenly, pulverize and make particle size be 5mm-10mm concrete powder;

[0037] (3) Concrete preparation: Weigh 75Kg of water, add surface enhancer, under the condition of stirring at a speed of 500 rpm, add concrete powder, add 6Kg polycarboxylate superplasticizer, continue stirring for 30min, add 250Kg cement, continue Stir for 50 minutes to make concrete;

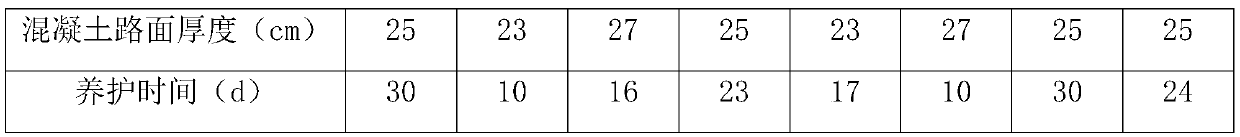

[0038] (4) Pavement pouring: the concrete prepared in step 3 is poured into a concrete pavement, the thickness of which is 25 cm, covered with a plastic film, and ma...

Embodiment 2

[0041] The difference between embodiment 2 and embodiment 1 is that attapulgite is not added in embodiment 2, and the others are consistent with embodiment 1.

Embodiment 3

[0043] The difference between Example 3 and Example 1 is that no polycarboxylate water reducer is added in Example 3, and the others are consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Water permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com