Insoluble sulfur extraction method and extraction system

A sulfur and extraction technology, applied in the field of insoluble sulfur continuous extraction system, can solve the problems of difficult to control product purity, long time, low extraction efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

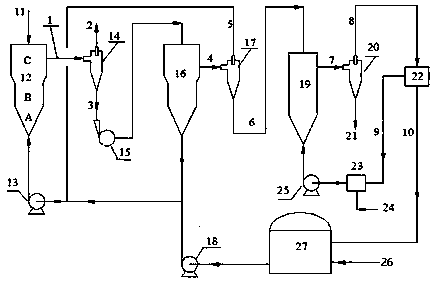

[0046] Using carbon disulfide as the extraction agent, the sulfur crude product particles (3mm) enter the first-stage fluidized bed extraction tower, the flow rate of the fluidized section is 6m / s, and the extracted particles enter the solid phase after being separated by the first-stage cyclone separator. Grinding to 100 mesh in the liquid phase pulverizer, the pulverized crude sulfur product is further extracted and cleaned in the secondary fluidized bed extraction tower, the flow velocity of the fluidized section of the secondary fluidized bed extraction tower is 2m / s, and Liquid-solid separation in the first-stage cyclone separator, and then the insoluble sulfur product is obtained after being treated by the dryer and the gas-solid cyclone separator. The drying temperature is 65°C, and the condensation temperature of the dry gas is 35°C. The yield of the obtained insoluble sulfur product is 38%, and the mass fraction of insoluble sulfur is 91.5%.

Embodiment 2

[0048] With carbon disulfide as the extraction agent, the sulfur crude product particles (2mm) enter the first-stage fluidized bed extraction tower, the flow rate of the fluidized section is 5m / s, and the extracted particles enter the solid phase after being separated by the first-stage cyclone separator. Grinding to 200 mesh in the liquid phase pulverizer, the pulverized crude sulfur product is further extracted and cleaned in the secondary fluidized bed extraction tower, the flow velocity of the fluidized section of the secondary fluidized bed extraction tower is 1.5m / s, and in The liquid-solid separation in the secondary cyclone separator, and then the insoluble sulfur product is obtained after being treated by the dryer and the gas-solid cyclone separator. The drying temperature is 63°C, and the drying gas condensation temperature is 40°C. The yield of the obtained insoluble sulfur product is is 37%, and the mass fraction of insoluble sulfur is 92.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com