Punched metal sheet micro-connection separating device

A separation device and micro-connection technology, which is applied in the direction of spring/shock absorber, vibration suppression adjustment, mechanical equipment, etc., can solve the problems of high noise, poor operation safety, and inability to separate parts directly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

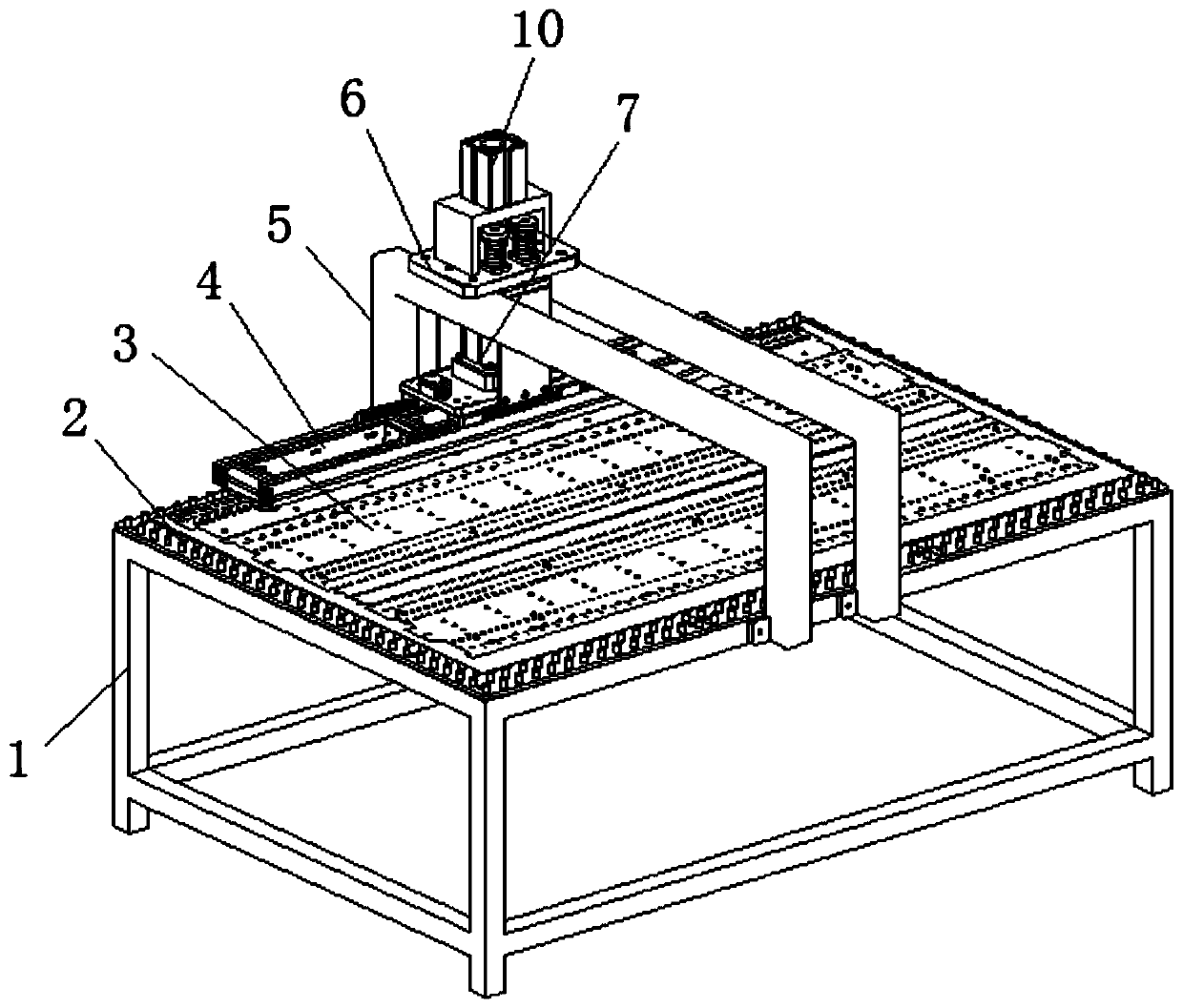

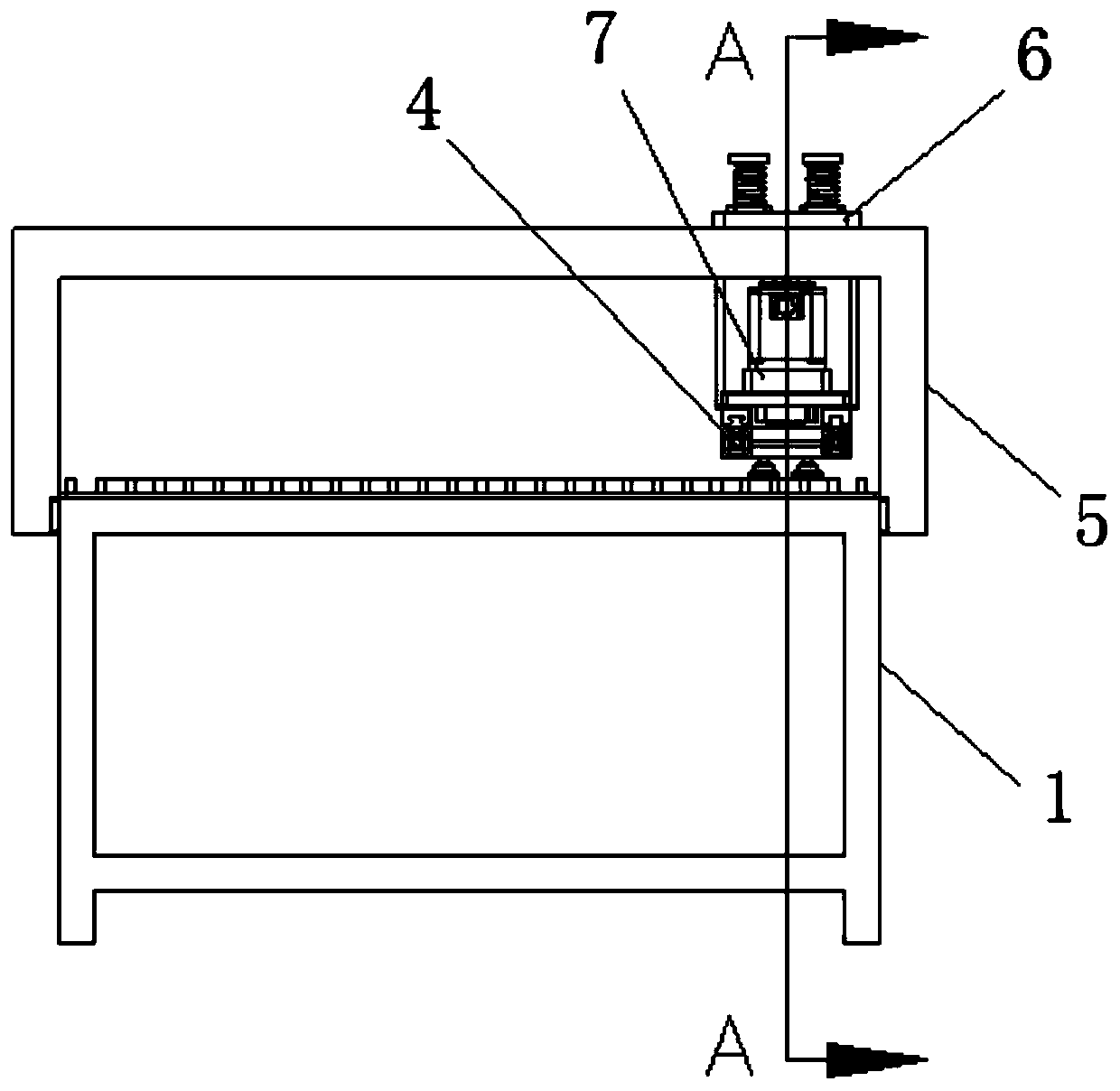

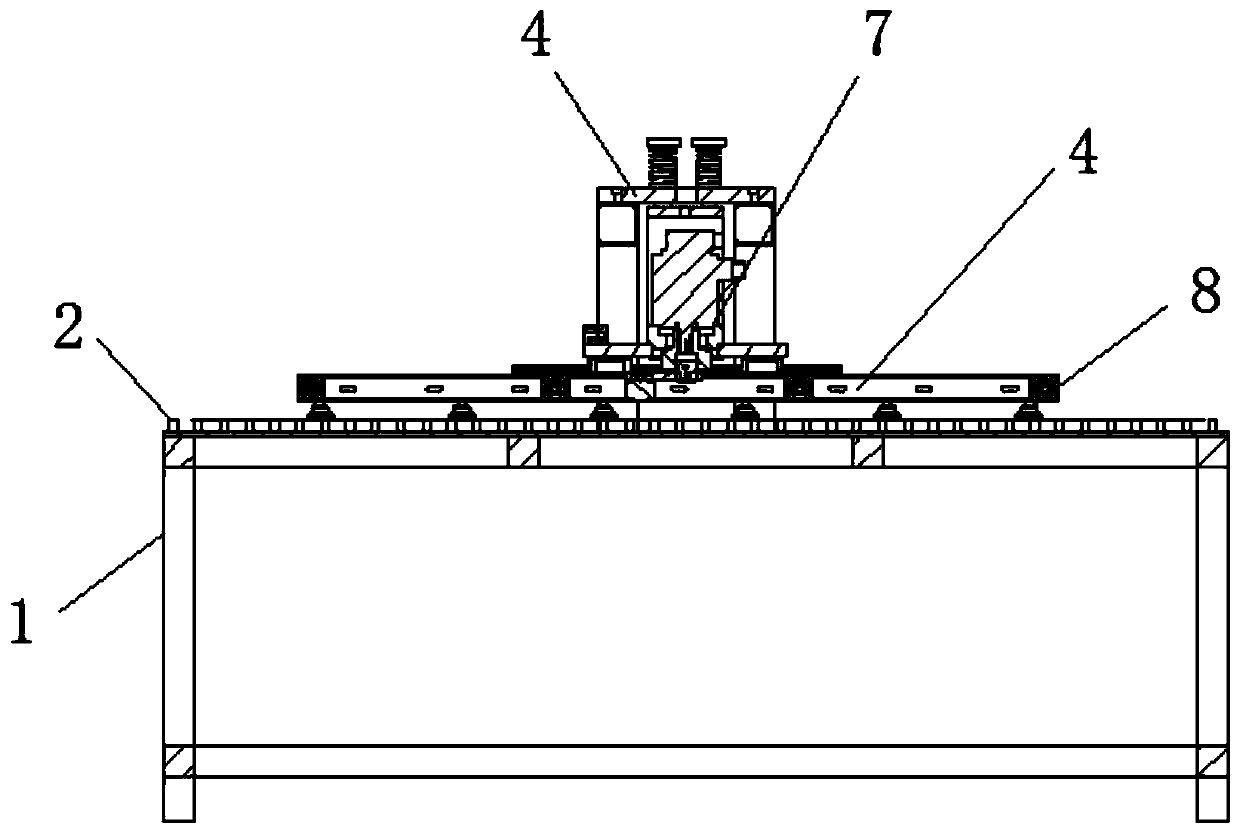

[0027] Attached below Figure 1-8 The specific embodiment of the invention will be further described. It should be noted here that the descriptions of these embodiments are used to help understanding of the invention, but are not intended to limit the invention. In addition, the technical features involved in the various embodiments of the invention described below may be combined with each other as long as they do not constitute a conflict with each other.

[0028] The invention provides a punching sheet metal micro-joint separation device, including a separation bracket 1, the upper end of the separation bracket 1 is provided with a vibrating blanking table 2, and a sheet metal part 3 is placed on the vibration blanking table 2, and the separation bracket 1 Two sets of fixed beams 5 are fixed on the top, and a suspension assembly 6 is installed on the fixed beam 5. A vibration separation assembly 7 is installed at the lower end of the suspension assembly 6, and the vibratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com