Modified General Tso water mill

An improved, water-milling technology, applied in the directions of hydroelectric power generation, the combination of wind turbines and water-energy converters, sustainable buildings, etc., can solve the problems of low production capacity, high fees, and insufficient power for small noodle mills.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

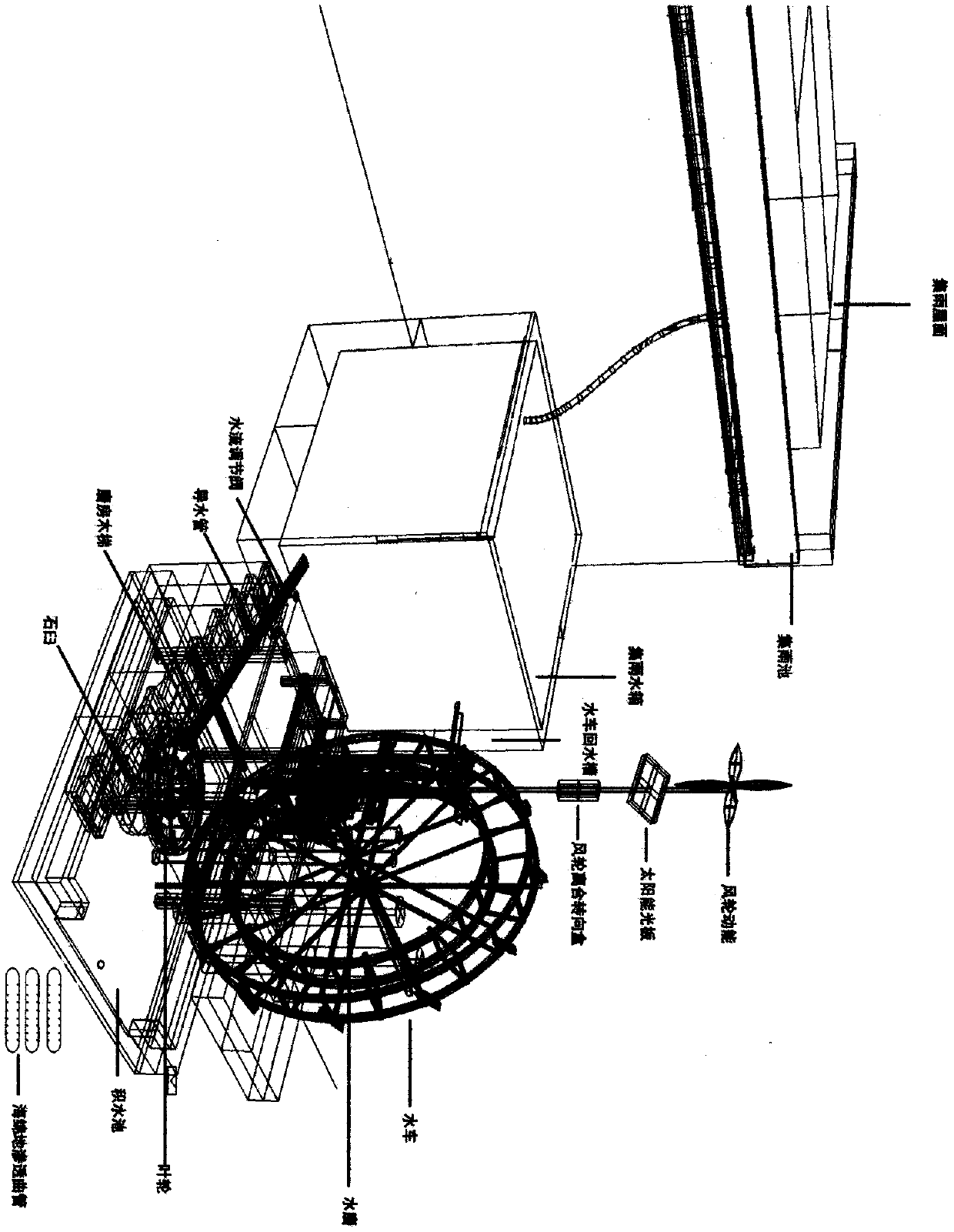

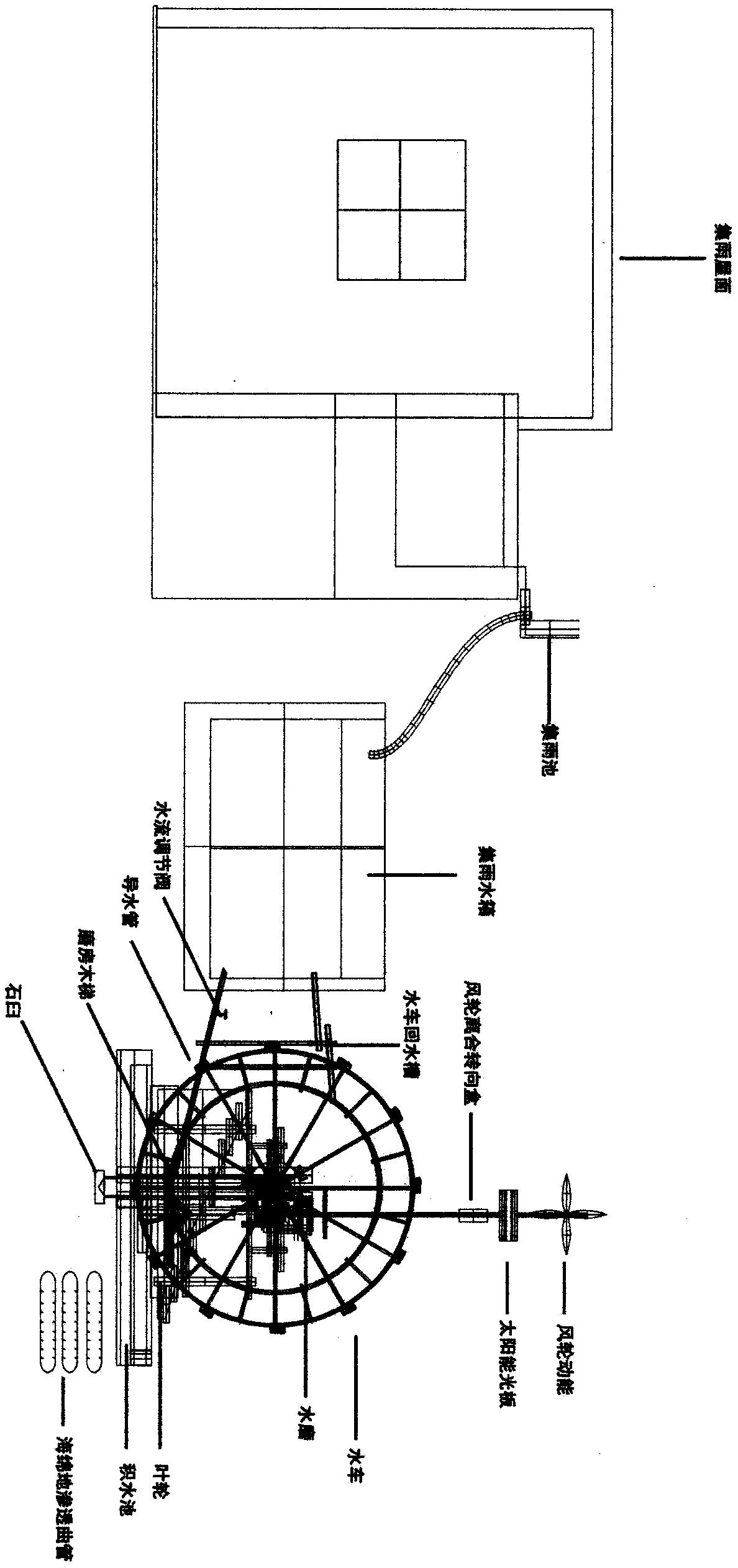

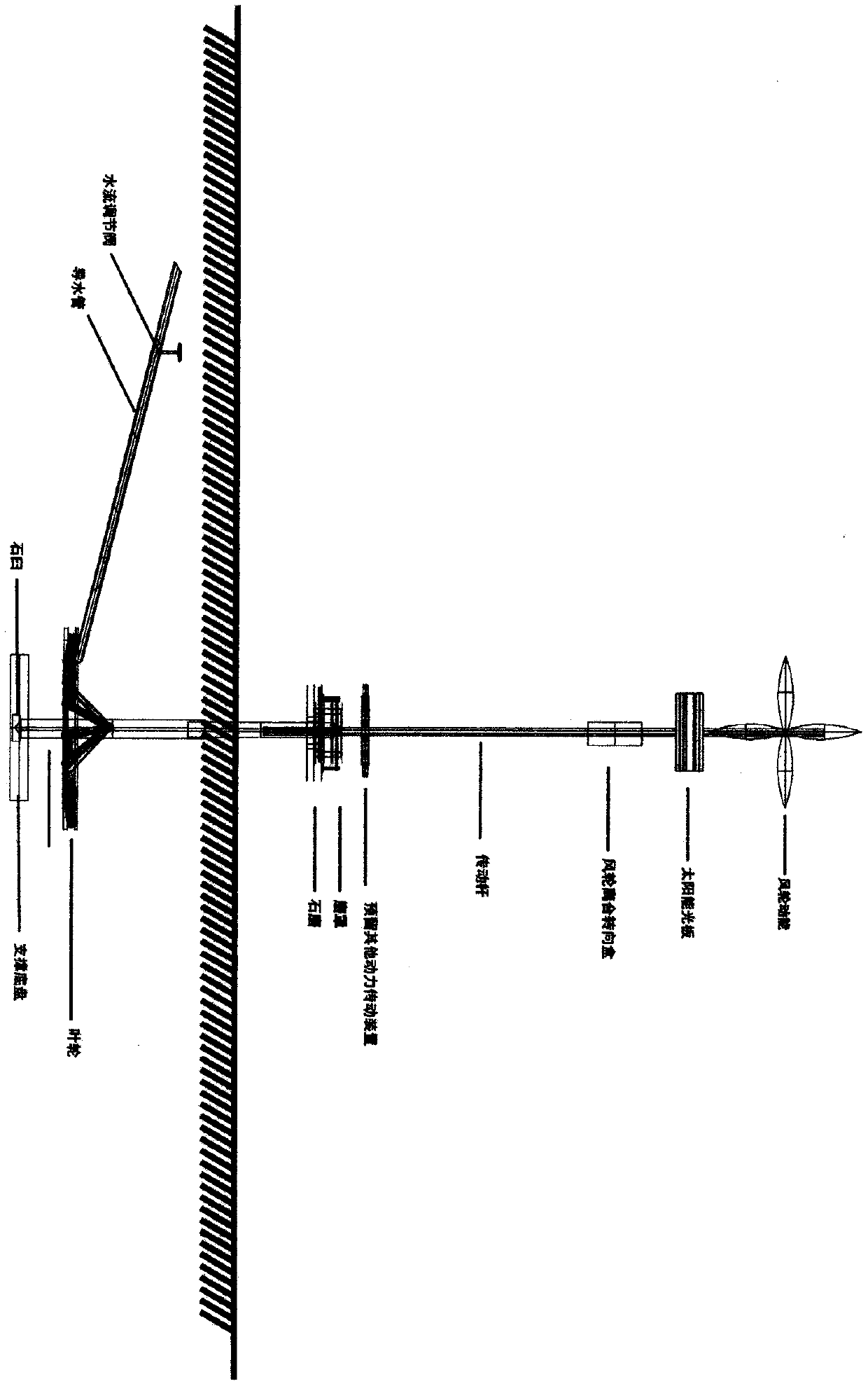

[0011] The water energy utilization method of the improved Zuogong water mill is that the natural rainwater on the roof flows into the aqueduct under the action of gravity, and a water flow regulating valve is installed in the middle of the aqueduct to adjust the rotation speed of the wheels and switch the water mill. The vane of the wheel is made of wood, and the surface of the vane is arc-shaped (it can be dug out from a log). The direction of the vane should face the water flow and directly bear the impact of the water. The two ends of the vane are embedded in two circles. Each of the two circles is composed of 8 curved planks. The two circles are connected to the central axis of the wheel with 8 wooden supports, and the circle boards are connected with the wooden boards. The outer circular joints are combined with cover boards, and the wooden boards and the wooden supports are staggered. In order to make the wheels firm, each wooden The support is respectively connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com