Miniaturized material irradiation device and use method thereof

An irradiation device and irradiation technology are applied in the field of miniaturized material irradiation devices, which can solve the problems of increasing the test cost, increasing the complexity of the irradiation device, and insufficient inflation, saving irradiation channel resources and improving comprehensive utilization efficiency. , the effect of reducing the exposure dose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

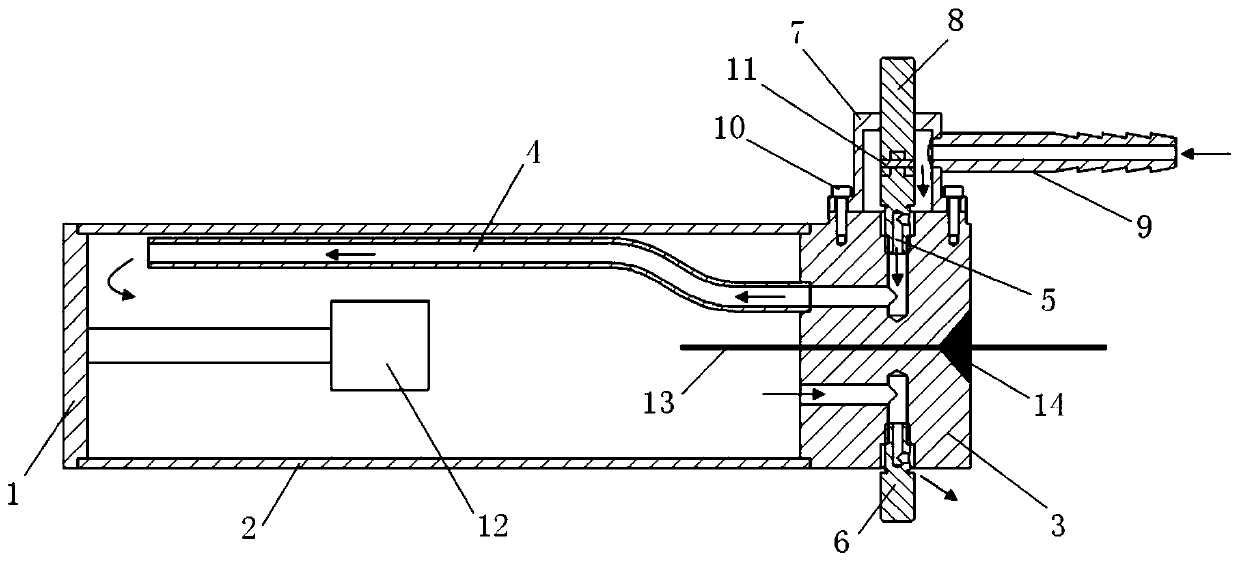

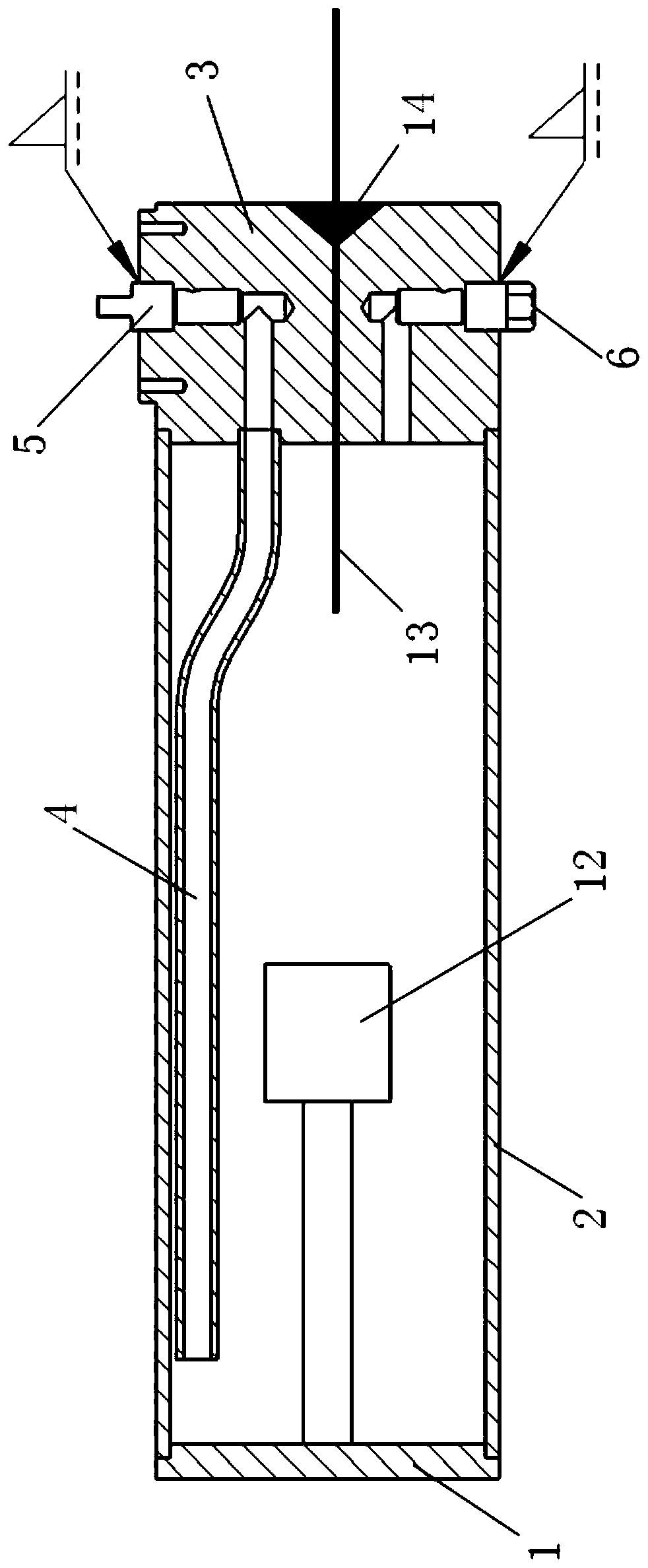

[0063] like figure 1 , figure 2 , image 3 , Figure 4 Shown:

[0064] A miniaturized material irradiation device, comprising an irradiation chamber A, one end of the irradiation chamber A is provided with an upper top cover 3, and the upper top cover 3 is provided with an air inlet hole and an air outlet hole;

[0065] Both the air inlet and the air outlet are located on the peripheral surface of the upper top cover 3, and an inflation screw 5 is arranged at the air inlet, and an exhaust screw 6 is arranged at the air outlet.

[0066] Design principle of the present invention is:

[0067] Since the structure of the traditional irradiation device is: including the irradiation chamber, the intake pipe and the exhaust pipe leading from the outside of the research reactor to the irradiation chamber inwardly, it is a semi-built-in structure, and its Part of the tube is built-in and part is outside, so that the radioactive rays can be directly transmitted to the top of the pi...

Embodiment 2

[0073] like figure 1 , figure 2 , image 3 , Figure 4 Shown:

[0074] On the basis of embodiment 1, further optimization technical scheme is:

[0075] The peripheral surface where the air inlet hole is located and the peripheral surface where the air outlet hole is located are two symmetrical peripheral surfaces. The air inlet and air outlet are arranged symmetrically, which can avoid the problems that the incoming gas is directly released to the air outlet, resulting in waste of gas and incomplete exhaust of the original gas.

Embodiment 3

[0077] like figure 1 , figure 2 , image 3 , Figure 4 Shown:

[0078] On the basis of embodiment 1, further optimization technical scheme is:

[0079] The axis of the air inlet hole or / and the air outlet hole is perpendicular or oblique to the corresponding peripheral surface.

[0080] specific, figure 1 As shown, when the vertical setting is adopted, corresponding communication channels need to be configured to communicate with the irradiation chamber A; not shown in the figure, when obliquely intersecting, the air inlet or / and air outlet can be directly obliquely connected to the irradiation chamber The room A is connected, or it can be connected with the irradiation chamber A through a connecting channel after being obliquely crossed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com