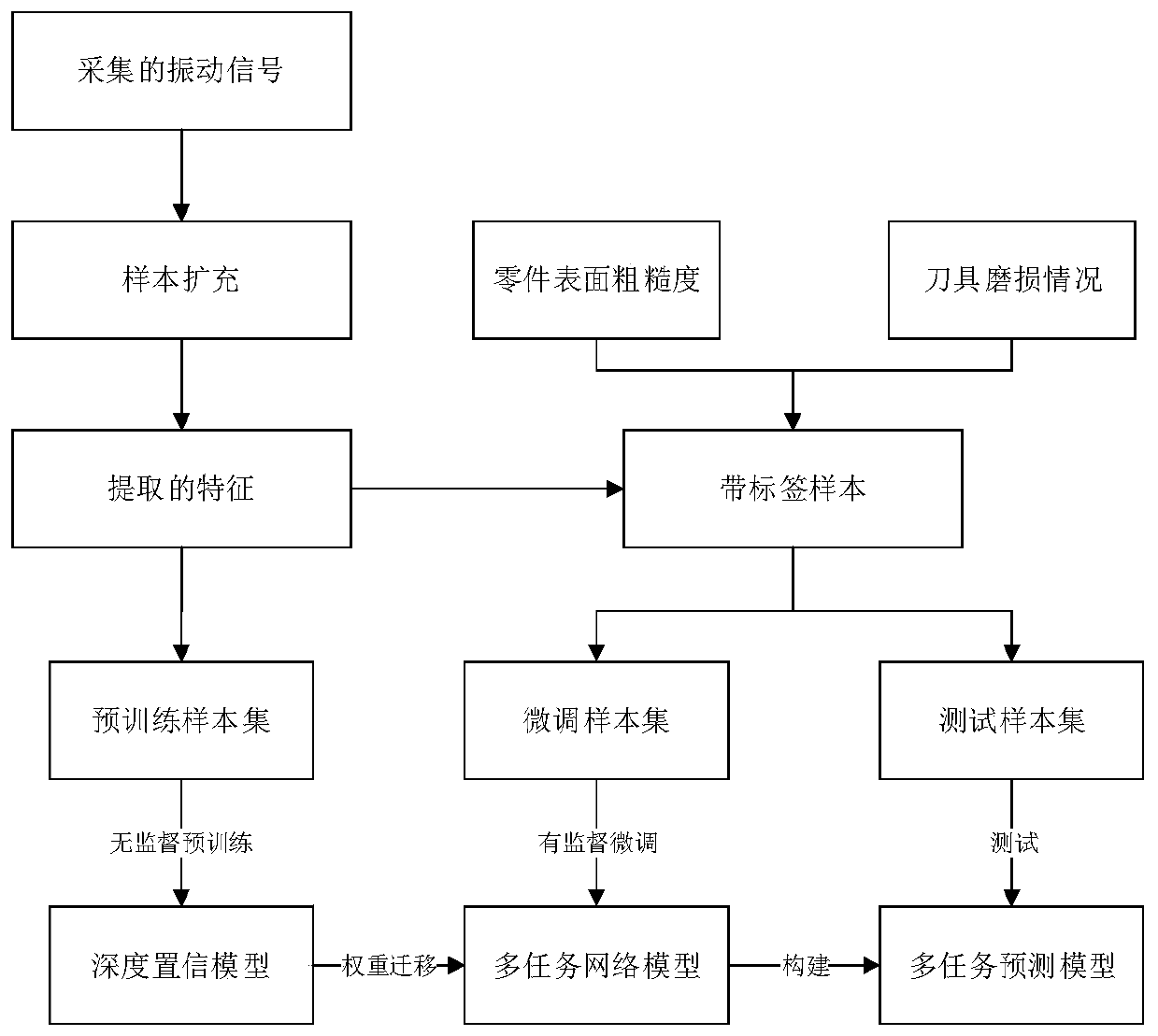

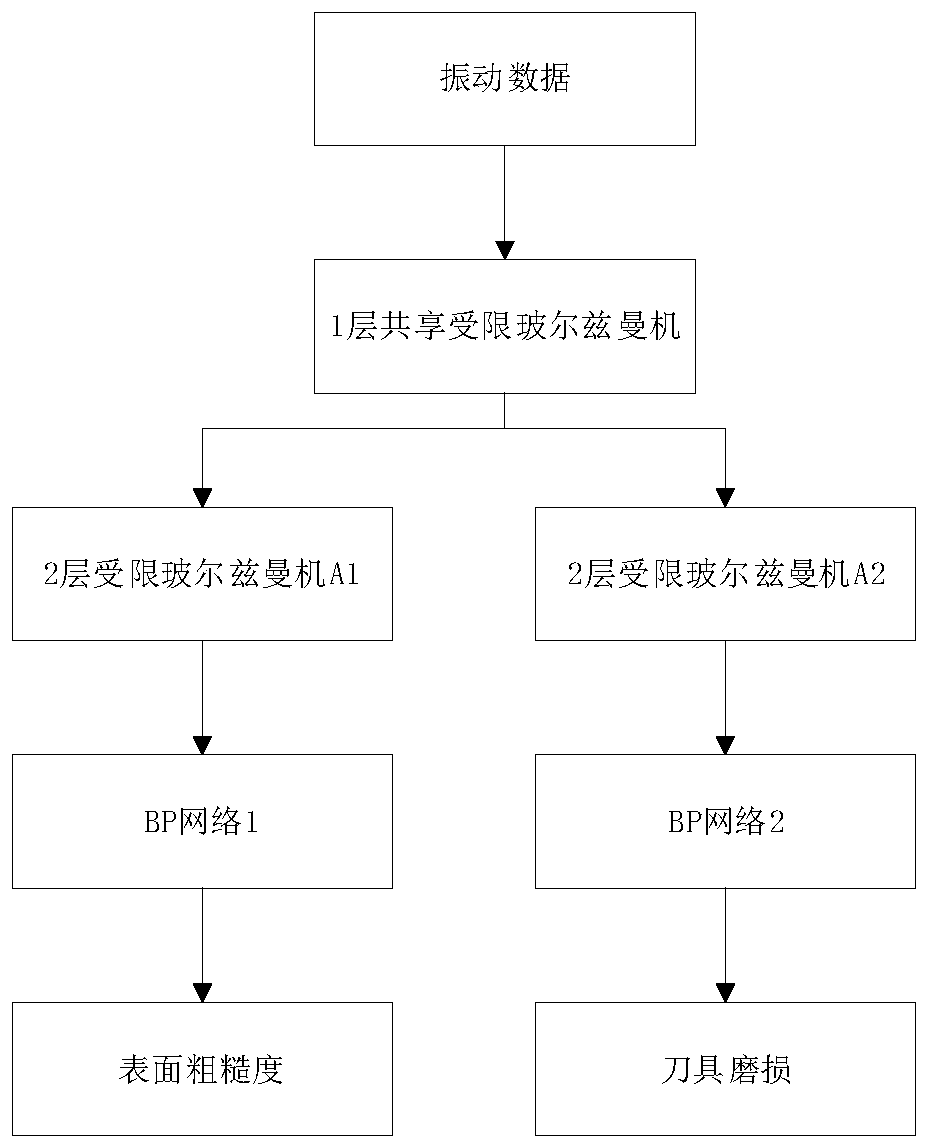

Part surface roughness and tool wear prediction method based on multi-task learning

A surface roughness, multi-task learning technology, applied in the field of machining, to reduce costs, avoid repetitive work, and improve production efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

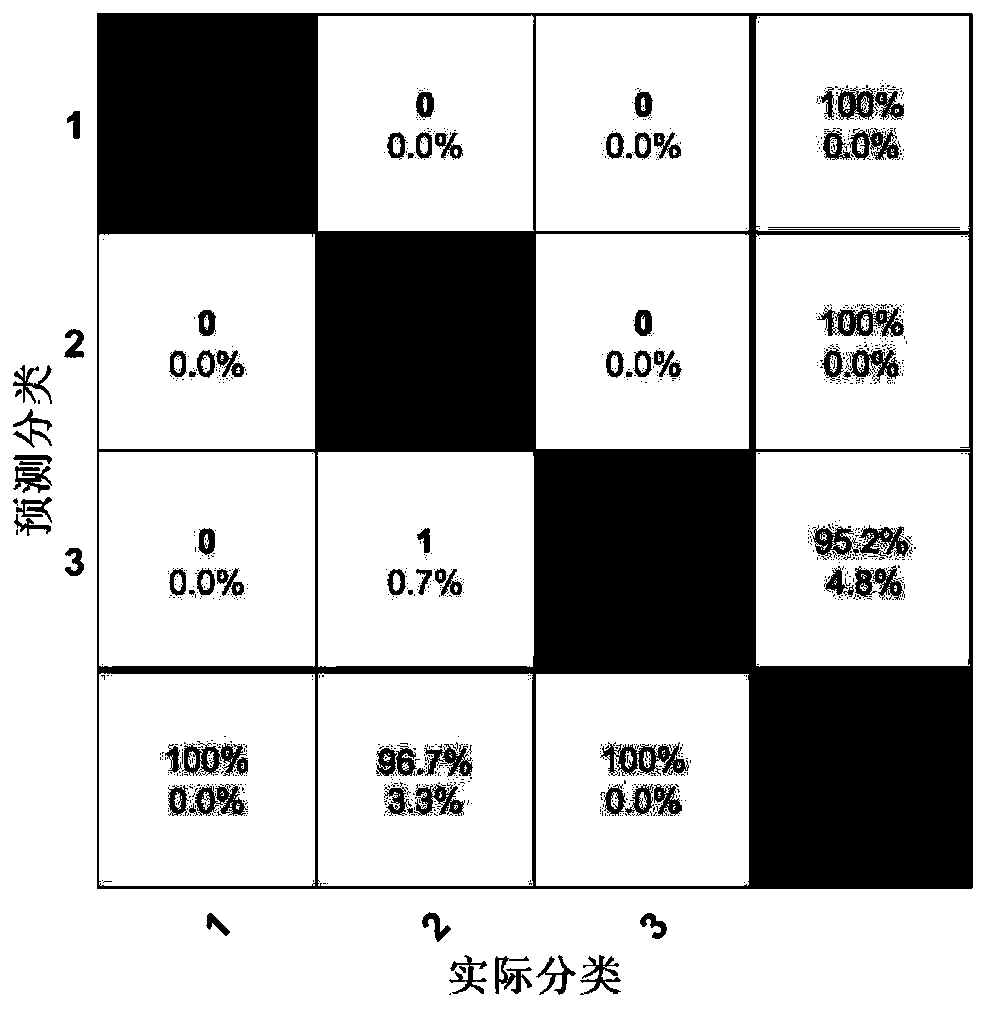

Examples

Embodiment Construction

[0049] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings.

[0050] On a three-axis vertical machining center, a cutting test was performed with a vertical milling cutter. Among them, the basic information of the three-axis vertical machining center is: the maximum travel of the X-axis, Y-axis and Z-axis is 710mm, 500mm and 350mm, and the maximum feed speed is 32m / min, 32m / min and 30m / min; The highest speed is 15000r / min. The basic information of the tool is: the tool type is vertical milling cutter; the tool material is carbide; the tool diameter is 10mm; the number of tool edges is 4. The basic information of the workpiece to be cut is: the material of the workpiece is 45# steel; the shape of the workpiece is 200mm X 100mm X 10mm. The cutting process parameters are: depth of cut is 2mm; feed rate is 80mm / min; spindle speed is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com