A vacuum high heat transfer anti-adhesion stable cushion and its preparation process

A preparation process, high heat transfer technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of difficult application, easy volatility, low heat transfer coefficient, etc., achieve good strength and physical properties, easy industrial production, chemical High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 A vacuum high heat transfer anti-adhesion and stable cushion and its preparation process

[0030] A vacuum high heat transfer anti-adhesion and stable cushion layer of this embodiment is a composite layer structure, which sequentially includes a bearing substrate layer, an adhesive layer and an anti-adhesion layer from the inside to the outside; the bearing substrate layer has a grid size of 1mm×1mm. , The thickness of 1mm glass fiber cloth layer, the adhesive layer is a paraffin layer with a thickness of 0.5mm, and the anti-stick layer is a compound oxide composed of magnesia, calcium oxide and lutetium oxide according to the weight ratio of 1:2:0.5 layer, wherein the particle size of magnesia is 0.1mm-1mm; the particle size of calcium oxide is 50μm-500μm; the particle size of lutetium oxide is 50μm-500μm.

[0031] The preparation process of the vacuum high heat transfer anti-adhesion and stable cushion layer of the present embodiment is carried out in sequen...

Embodiment 2-4

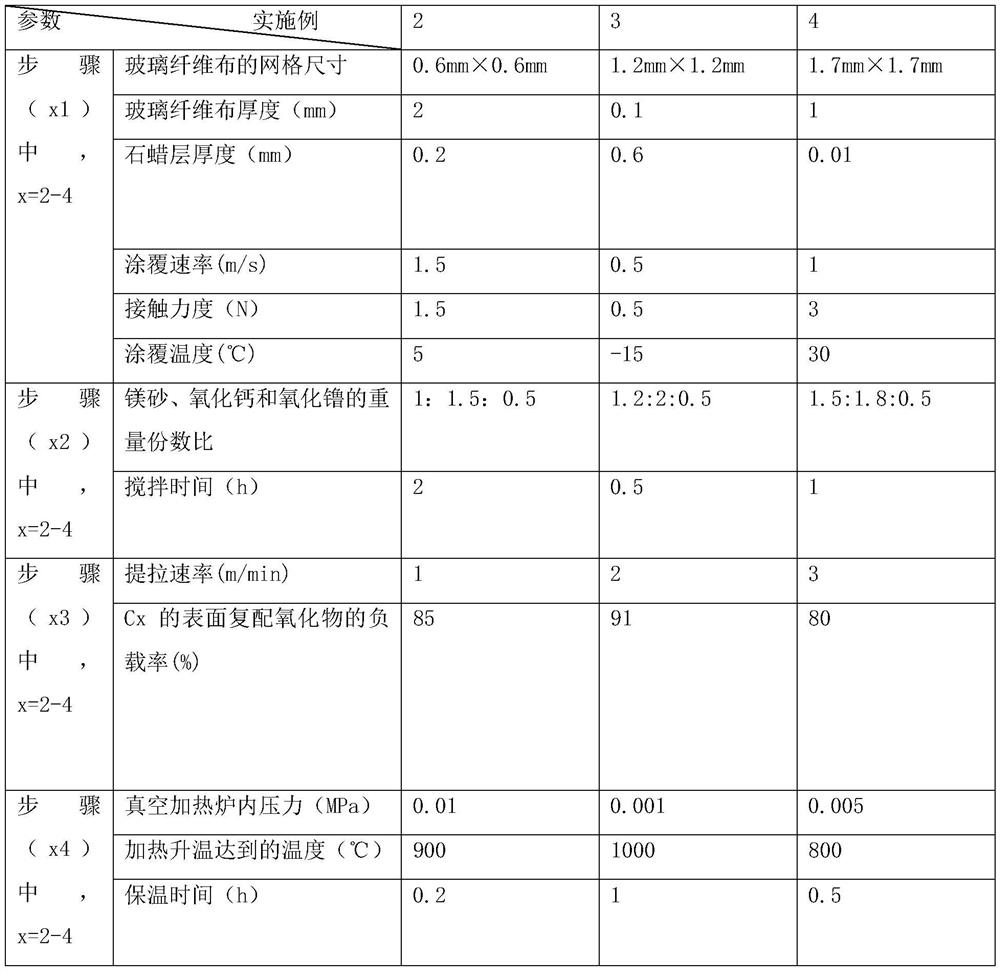

[0036] Example 2-4 Vacuum high heat transfer anti-blocking and stable cushion and its preparation process

[0037] Embodiment 2-4 is respectively a kind of vacuum high heat transfer anti-adhesion and stable cushion layer and preparation process thereof, and the structure of cushion layer and preparation process are similar to embodiment 1, and the difference is only: the parameters in the preparation process are different, see specifically The following table.

[0038]

Embodiment 5

[0039] Example 5 Thermal Conductivity Test of Cushion Layer

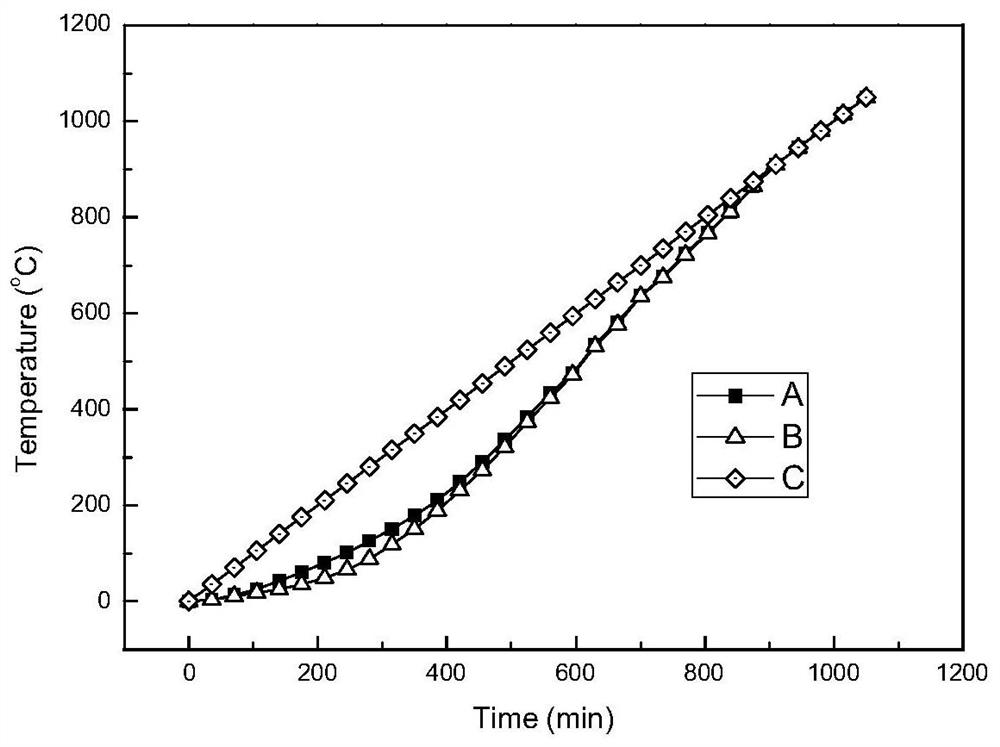

[0040]In this example, the vacuum heating heat conduction test was carried out on the cushion layer prepared in Example 1. The test method was as follows: in a carbon tube furnace, the cushion layer was placed between the crucible and the graphite heating body, and a temperature measuring thermocouple was placed at the bottom of the crucible. The inside of the furnace body is evacuated to 0.001MPa, and then programmed to heat up at a heating rate of 1°C / min. Read the thermocouple readings. Under the same test conditions, the thermocouple degrees without the cushion are compared and analyzed, and the result is obtained. figure 1 Shown curve, in the figure: curve A is the test curve without the cushion layer, curve B is the test curve with the cushion layer added, and curve C is the program test curve.

[0041] Depend on figure 1 It can be seen that, when the temperature is lower than 250°C using the heating curve A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com