Large-area quasi-single crystal perovskite film closed circulation preparation device and preparation method thereof

A technology of closed circulation and preparation of devices, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of material waste, large internal resistance of the film, environmental pollution, etc., and achieve simple device structure and mild preparation conditions Controllable, simple and effective preparation method and environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

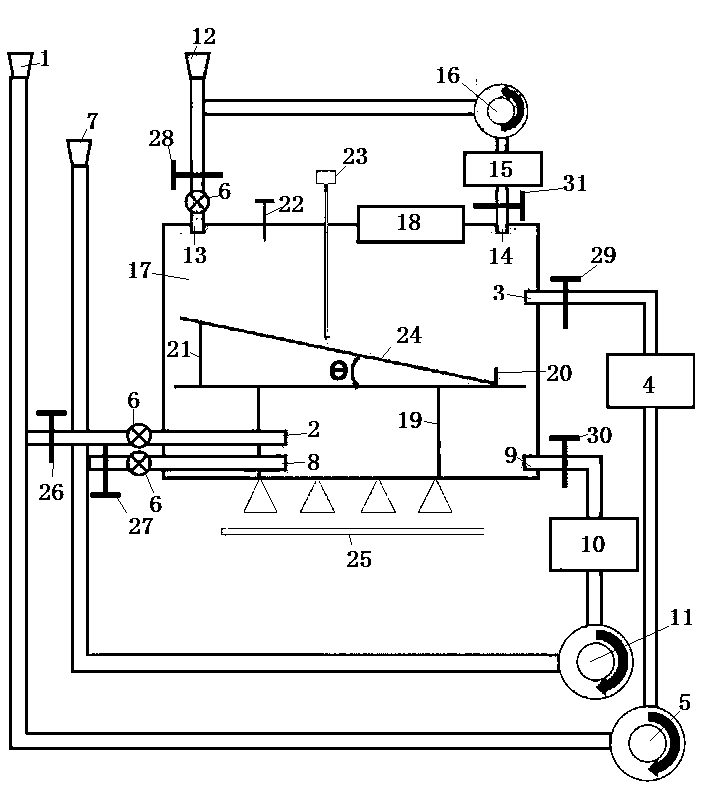

Image

Examples

Embodiment 1

[0052] Embodiment 1: prepare large-area quasi-single crystal perovskite film as follows:

[0053] S1, MAPbI 3 Preparation of perovskite precursor solution: MAI and PbI 2 Add it into the mixed solvent of N,N-dimethylformamide and dimethyl sulfoxide with a volume ratio of 4:1 in an equimolar ratio, and stir the mixture at 70°C for 6 hours to prepare a concentration of 1.2mol / LMAPbI 3 Perovskite Precursor. Among them, MA + for CH 3 NH 3 + .

[0054]S2. Preparation of a large-area reaction substrate: on a cleaned large-area transparent FTO conductive glass substrate, a tin metal grid electrode is prepared by vacuum thermal evaporation; A nanometer-thick tin dioxide electron transport layer; electrophoresis is used to deposit aminated graphene quantum dots on the surface of the tin dioxide electron transport layer.

[0055] S3. Growth of large-area quasi-single crystal perovskite film: open the transparent chamber door, place the large-area reaction substrate prepared in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com