Fabric continuous color printing system

A fabric and color printing technology is applied in the field of automatic printing machinery for garment fabrics, which can solve the problems of difficult continuous and fully automatic printing processing, and the inability to realize continuous and automatic tiling of garment fabrics, so as to ensure smoothness and improve adsorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

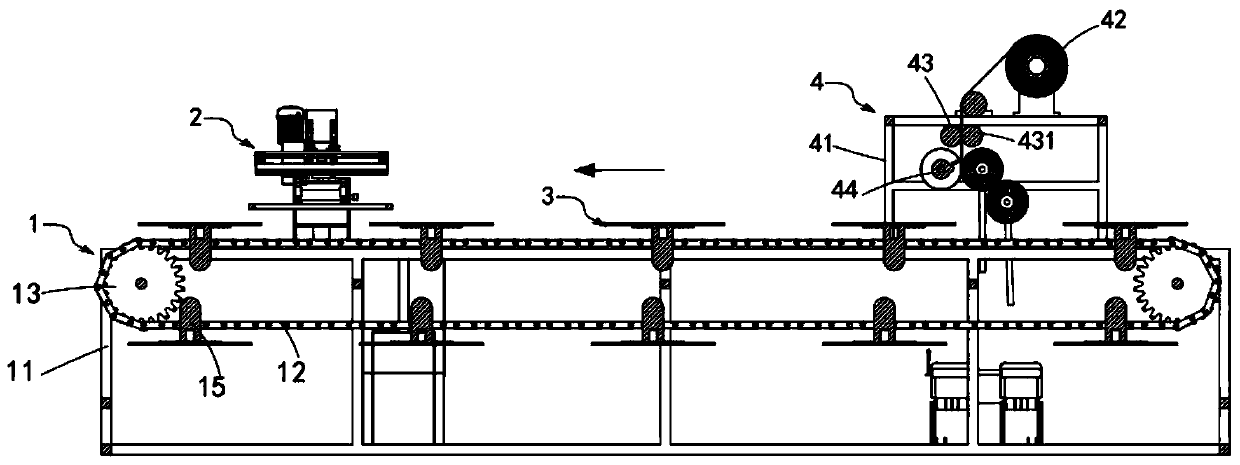

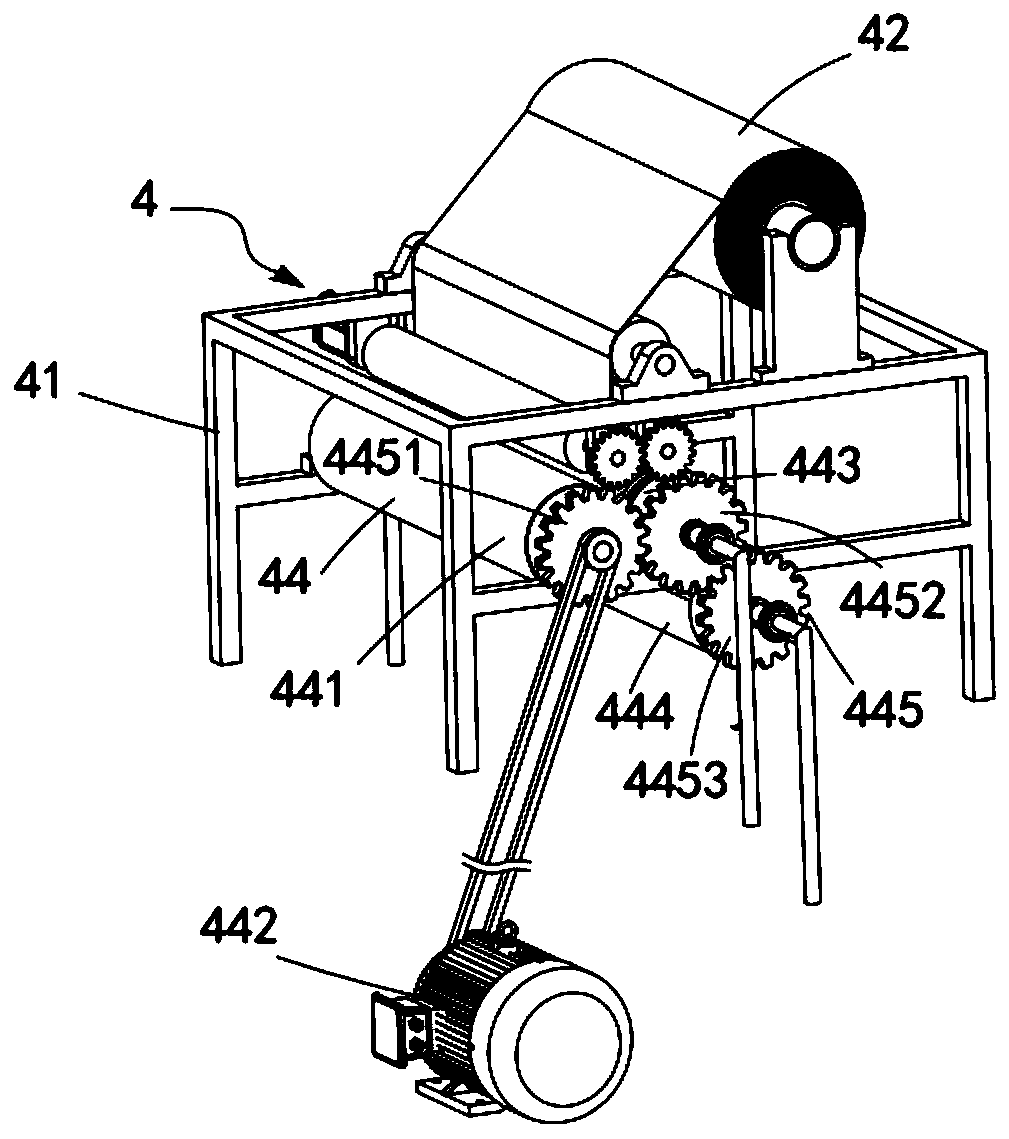

[0080] Such as Figure 1 to Figure 3 As shown, a continuous color printing system for fabrics includes a feeding line 1 and at least one set of printing equipment 2 arranged on the conveying path of the feeding line 1. Horizontally arranged processing table 3 conveying, also includes:

[0081] Automatic feeding device 4, described automatic feeding device 4 is installed on the top of described feeding line 1, and it comprises feeding rack 41, the textile material roll 42 that places feeding rack 41 top, is positioned at the textile material roll 42 below The unwinding mechanism 43 and the slitting mechanism 44 positioned below the unwinding mechanism 43, the two ends of the textile material roll 42 are erected on the described feed frame 41, and freely rotated, the output end of the textile material roll 42 part is clamped by the unwinding mechanism 43 and unrolled downwards, and the cutting mechanism 44 cuts the clothing fabrics unwound from the textile material roll 42, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com