A kind of rolling equipment for trench construction

A rolling and ditching technology, which is applied in the field of rolling machines, can solve problems such as subsidence, side slopes that cannot be compacted, and loose soil layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

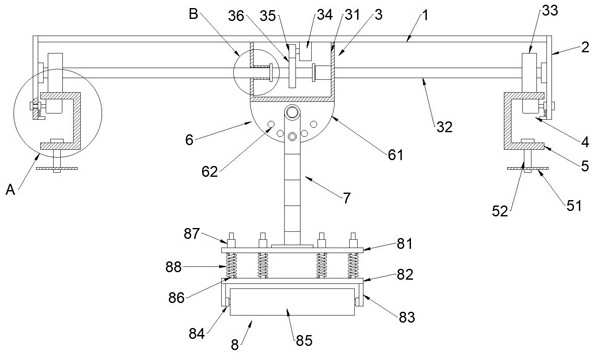

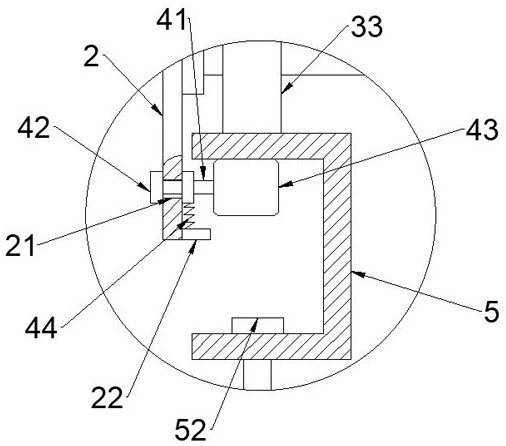

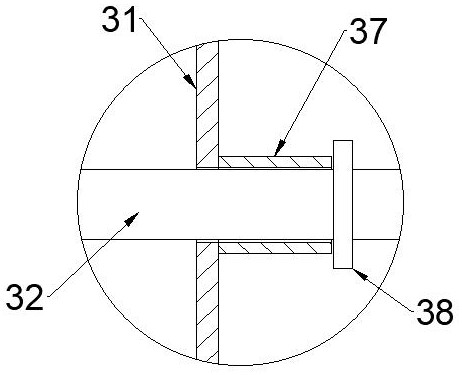

[0028] like figure 1 As shown, a rolling device for trench construction includes a top plate 1, a drive assembly 3, a slide rail 5 and a rolling assembly 8. Side plates 2 are installed on both sides of the bottom of the top plate 1, and the side plates 2 and the top plate 1 are connected to each other. Vertical, the bottom of the top plate 1 is equipped with a drive assembly 3, a pair of parallel slide rails 5 are installed on the ground, the drive assembly 3 is close to the slide rail 5, the friction between the drive assembly 3 and the slide rail 5 Under the action of force, the drive assembly 3 and the top plate 1 can be moved on the slide rail 5 along the extension direction of the slide rail 5. The bottom of the drive assembly 3 is equipped with a rotation adjustment assembly 6, and a connecting member 7 is installed on the rotation adjustment assembly 6. , the bottom of the connecting member 7 is equipped with a rolling assembly 8, the rolling assembly 8 acts on the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com