Silicon rod cutting process

A cutting process and technology for silicon rods, which are used in manufacturing tools, stone processing equipment, fine working devices, etc., can solve problems such as the limitation of the length and width of silicon wafers, increase the difficulty and cost of silicon rod processing, and improve the utilization rate, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings and embodiments. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

[0025] The technical scheme of the specific implementation of the present invention is:

[0026] like Figure 1 to Figure 3 As shown, the present invention provides a silicon rod cutting process, comprising the following steps:

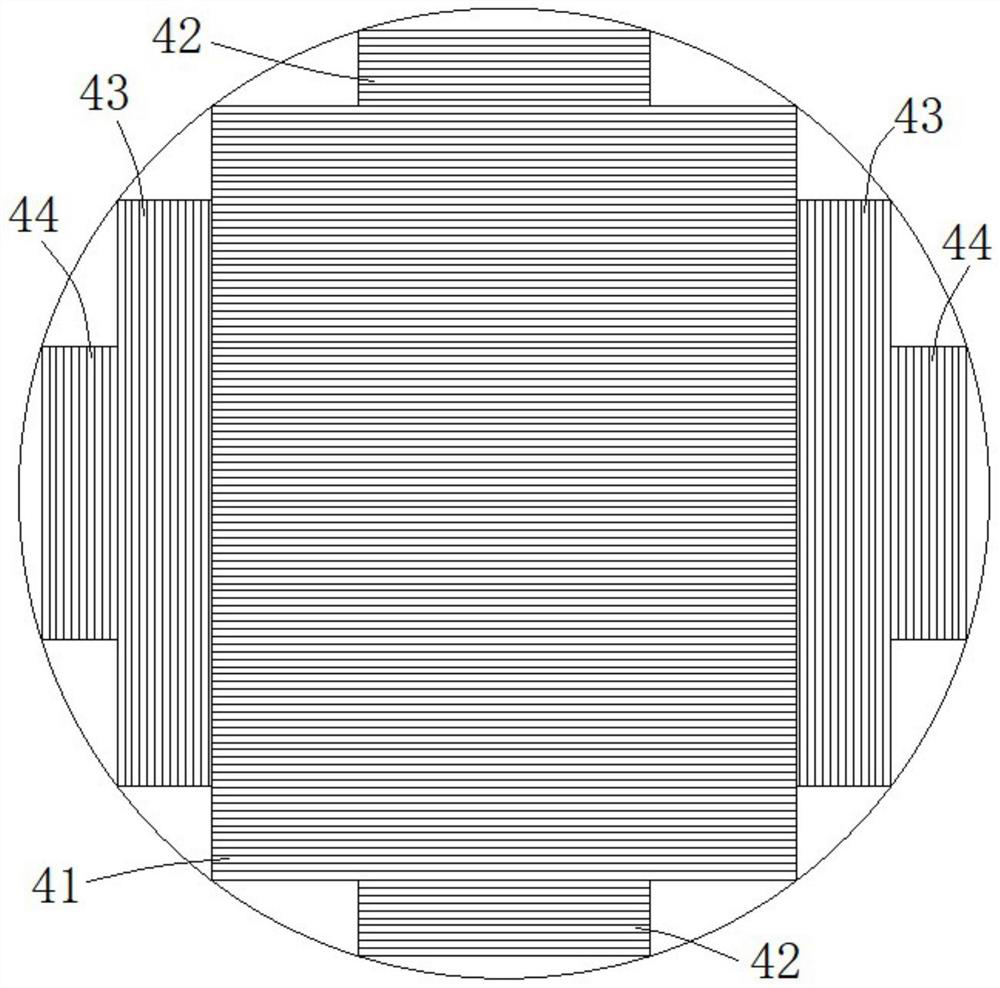

[0027] Root the silicon rod 1, and cut out the central silicon block 21 and the four side skins extending in the same direction as the silicon rod 1; The extension direction of the center silicon block 21 is vertical; the four edge skins include: a pair of first edge skins 31 cut from both sides of the cross section of the central silicon block 21 in the length direction, and a pair of first edge skins 31 cut from b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com