Device and method for preparing metal film through area expansion in vacuum environment

A technology of area expansion and metal thin film, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of cumbersome process, many control factors, easy material consumption, etc., and achieve simple preparation process, high material utilization rate, and reliable The effect of less control variables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

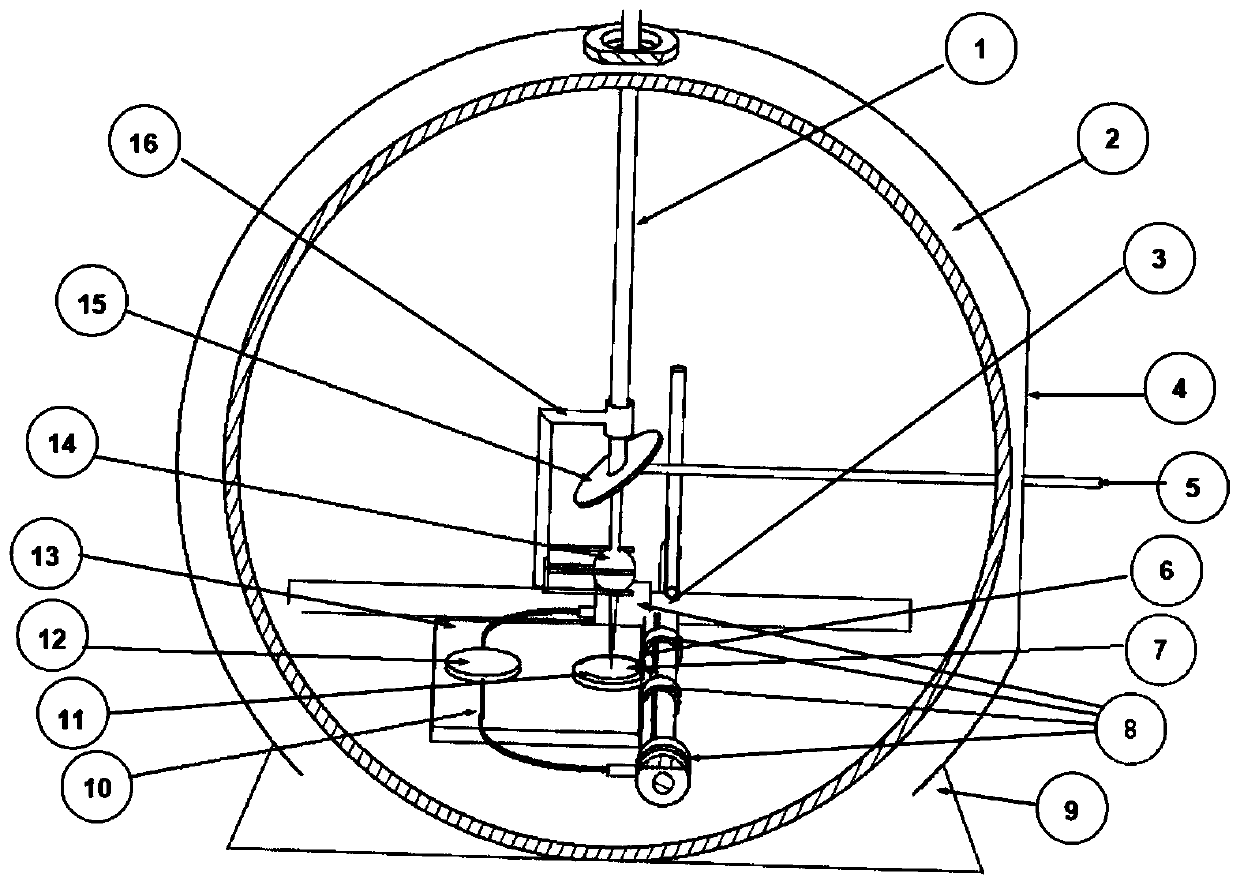

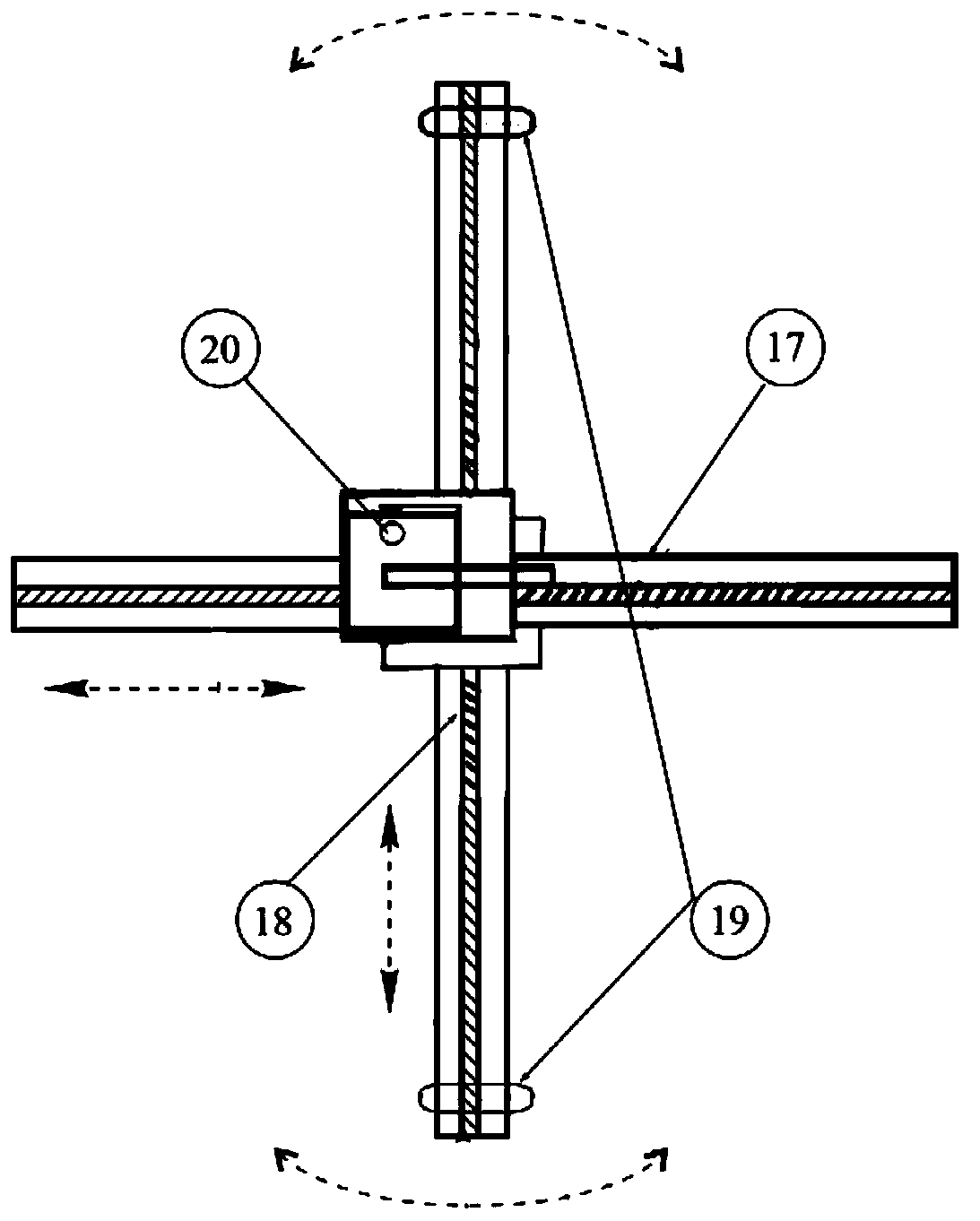

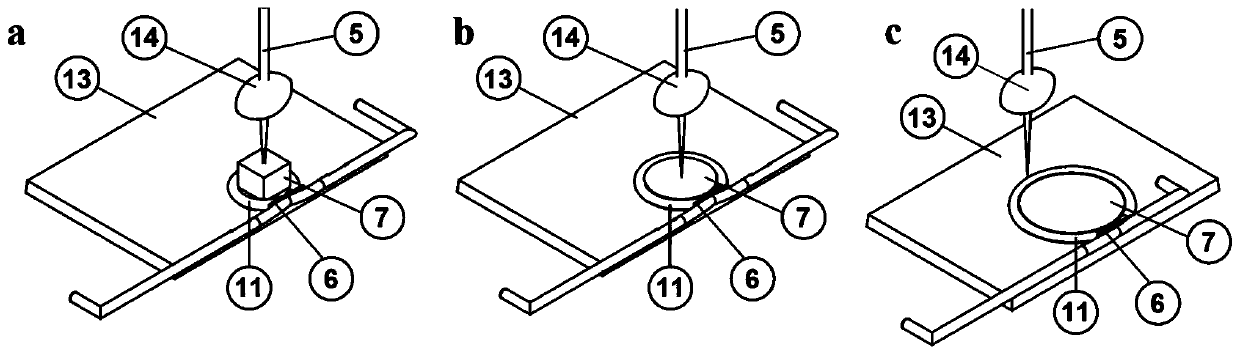

[0071] A device for preparing metal thin films by area expansion in a vacuum environment, the schematic diagram of which is shown in figure 1 Shown, comprise vacuum furnace 2, be provided with liftable test bench 13 in vacuum furnace 2, be provided with pressurization device 1 above test bench 13, pressurization device 1 is provided with reflective plane mirror 15 and converging convex lens 14, test bench 13 Fixed on the manipulator device 3, the partial top view of the manipulator device is as follows figure 2 As shown, the surface of the test bench 13 is provided with molybdenum wire rings, the molybdenum wire rings are fixed on the X-axis 18 and the Y-axis 17, the molybdenum wire rings are metal rings that can expand the area, and the molybdenum wire rings are fixed on the manipulator device 3; the manipulator device 3 includes X Axis 18, Y axis 17 and Z axis 20, the manipulator device 3 is provided with a slideway, which can realize the sliding of the XYZ axis 20, the rot...

Embodiment 2

[0081] The structure of the device for preparing a metal thin film by area expansion in a vacuum environment in this embodiment is the same as that in Embodiment 1.

[0082] The preparation process of the metal thin film is the same as in Example 1, the difference is that the 6061 aluminum alloy block is replaced by pure gallium metal, and the molybdenum wire is replaced by GH4169 superalloy wire to carry out the preparation experiment of the gallium thin film.

[0083] The experimental environment was the same as that of Example 1. A 5×5×5 mm cube of lead-tin alloy with a weight of 0.74 g was placed in the center of the furnace, and the position of the condensing convex lens was adjusted by a manipulator. According to the formula of viscosity and temperature and the calculation formula of shrinkage and viscosity, combined with the freezing point of gallium metal below 0°C, in this example, the heating temperature T(k) ranges from 30°C to 32°C (the melting point of gallium meta...

Embodiment 3

[0085] The structure of the device for preparing a metal thin film by area expansion in a vacuum environment in this embodiment is the same as that in Embodiment 1.

[0086] The metal film preparation process environment is the same as in Example 1, the difference is that the 6061 aluminum alloy block is replaced by a lead-tin alloy containing 60% tin and 40% lead, and the molybdenum wire is replaced by a GH4169 superalloy wire (which has a good comprehensive performance), to carry out the preparation experiment of lead-tin alloy thin film.

[0087] The experimental environment is the same as that of Example 1. Put a 5×5×5mm cube of lead-tin alloy with a weight of 0.55g in the center of the furnace, adjust the position of the converging convex lens with a manipulator, and calculate according to the formula of viscosity and temperature, shrinkage rate and viscosity The formula, combined with the good toughness of the lead-tin alloy, in this example, the heating temperature T(k)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com