Doped carbon material catalyst as well as preparation method and application thereof

A technology of catalysts and carbon materials, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as harsh reaction conditions, and achieve the effect of inhibiting hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

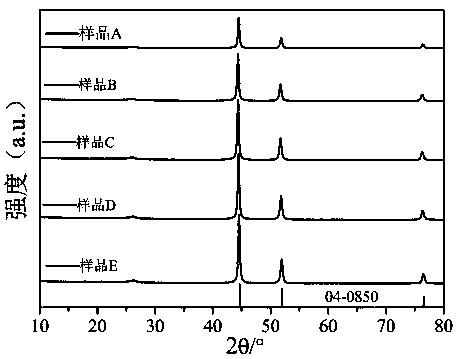

[0029] 1.4 g of polyvinyl alcohol and 0.2 g of polyvinyl pyrrolidone were dispersed in 20 mL of aqueous solution, and the above solution was heated and stirred in a 70° C. water bath for 1 hour. After the polymer is completely dispersed and uniform, the solution is cooled. 1.0 mL of glacial acetic acid and 1.4 g of nickel chloride were added to the solution, and stirred for 12 hours to prepare an electrospinning solution. Place the thin film in a quartz boat with 0.1% H 2 Ar atmosphere, calcination at 500 ℃ for 1h. The prepared material is Sample A.

Embodiment 2

[0031] Disperse 1.0 g of polyvinylpyrrolidone, 0.2 g of polyvinyl alcohol and 0.2 g of polyacrylamide in 20 mL of aqueous solution, and heat and stir the above solution in a water bath at 80° C. for 1 hour. After the polymer is completely dispersed and uniform, the solution is cooled. 1.2 mL of glacial acetic acid and 1.4 g of nickel nitrate were added to the solution, and stirred for 12 hours to prepare an electrospinning solution. Place the film in a quartz boat with 0.1% H 2 Calcined at 600 °C for 3 h in an Ar atmosphere. The material prepared was Sample B.

Embodiment 3

[0033] Disperse 1.0 g of polyvinylpyrrolidone, 0.2 g of polyvinyl alcohol and 0.2 g of polyacrylamide in 20 mL of aqueous solution, and heat and stir the above solution in a 90° C. water bath for 1 hour. After the polymer is completely dispersed and uniform, the solution is cooled. 0.7 g of nickel nitrate, 0.7 g of nickel chloride and 1.5 mL of glacial acetic acid were added to the solution, and stirred for 12 hours to prepare an electrospinning solution. Place the thin film in a quartz boat with 0.1% H 2 N 2 Calcined at 700°C for 4h in atmosphere. The prepared material is Sample C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com