Method for preparing high-whiteness short-column submicron-scale alpha-hemihydrate gypsum by using desulfurized gypsum

A desulfurization gypsum, sub-micron technology, applied in the field of high-whiteness short-column sub-micron α-hemihydrate gypsum, which can solve the problems of secondary pollution and achieve strong injectability, high strength, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

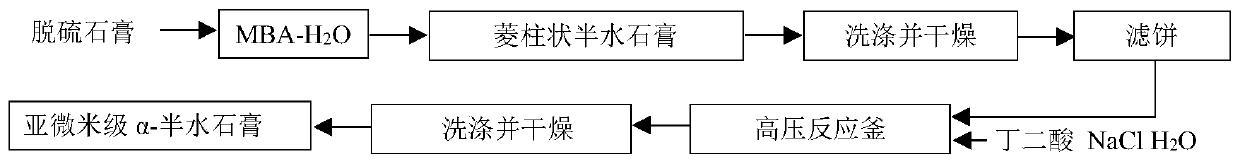

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: The specific operation is as follows

[0034](1) Preparation of rhombohedral product:

[0035] Prepare N.N'-methylenebisacrylamide, water, and desulfurized gypsum according to N.N'-methylenebisacrylamide: desulfurized gypsum: water = 0.3g:9g:100mL, prepare a reaction slurry and place it in a polytetrafluoroethylene Ethylene reactor, and heated to 120 ° C for 140 minutes;

[0036] (2) filtering the slurry obtained in step (1), and washing the obtained filter cake with deionized water until neutral;

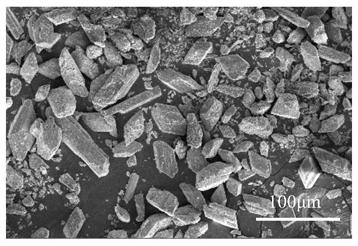

[0037] (3) Drying: Dry the product obtained in step (2) at 100°C for 4 hours to obtain the intermediate product, as shown in the attached figure 2 As shown, the product is a prismatic product with uniform appearance.

[0038] (4) The intermediate product, NaCl, succinic acid, ethylene glycol, and water are prepared according to the mass ratio: intermediate product: NaCl: succinic acid: ethylene glycol: water=18:3:0.02:0.2:100 to prepare a reaction slurry; ...

Embodiment 2

[0042] Embodiment 2: specific operation is as follows

[0043] (1) Preparation of rhombohedral product:

[0044] Prepare N.N'-methylenebisacrylamide, water, and desulfurized gypsum according to N.N'-methylenebisacrylamide: desulfurized gypsum: water = 0.3g:9g:100mL and place the reaction slurry in polytetrafluoroethylene Reactor, and heated to 120 ℃ for 140min;

[0045] (2) filtering the slurry obtained in step (1), and washing the obtained filter cake with deionized water until neutral;

[0046] (3) drying: drying the product obtained in step (2) at 100°C for 4 hours to obtain the intermediate product;

[0047] (4) intermediate product, NaCl, succinic acid, ethylene glycol, water according to mass ratio: intermediate product: NaCl: succinic acid: ethylene glycol: water=18:3:0.02:0.96:100 preparation reaction slurry;

[0048] (5) The reaction slurry obtained in (4) was placed in a polytetrafluoroethylene reactor, and reacted for 3 hours at a temperature of 120° C. and a sti...

Embodiment 3

[0050] Embodiment 3: specific operations are as follows

[0051] (1) Preparation of rhombohedral product:

[0052] Prepare N.N'-methylenebisacrylamide, water, and desulfurized gypsum according to N.N'-methylenebisacrylamide: desulfurized gypsum: water = 0.3g:9g:100mL and place the reaction slurry in polytetrafluoroethylene Reactor, and heated to 120 ℃ for 140min;

[0053] (2) filtering the slurry obtained in step (1), and washing the obtained filter cake with deionized water until neutral;

[0054] (3) drying: drying the product obtained in step (2) at 100°C for 4 hours to obtain the intermediate product;

[0055] (4) intermediate product, NaCl, succinic acid, ethylene glycol, water according to mass ratio: intermediate product: NaCl: succinic acid: ethylene glycol: water=18:3:0.02:1.61:100 preparation reaction slurry;

[0056] (5) The reaction slurry obtained in (4) was placed in a polytetrafluoroethylene reactor, and reacted for 3 hours at a temperature of 120° C. and a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com