Chitosan/bacterial cellulose composite aerogel adsorbent and preparation method and application thereof

A technology of bacterial cellulose and composite aerogel, which is applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc. The effect of improving mechanical properties and stability, low cost and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

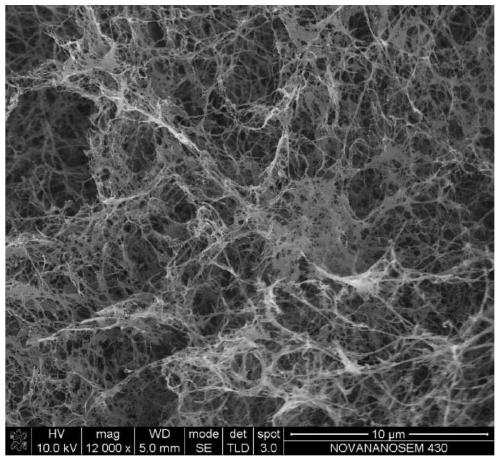

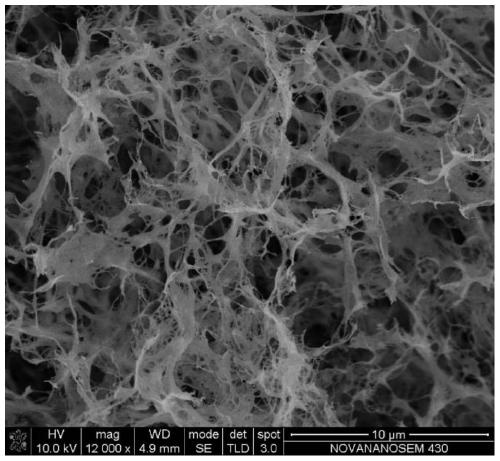

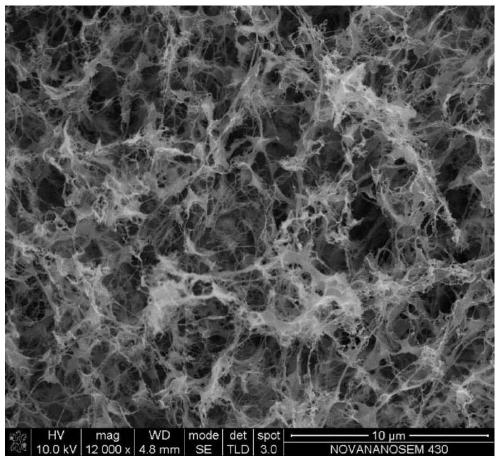

Image

Examples

Embodiment 1

[0040] (1) Put the bacterial cellulose hydrogel into 2mol / L NaOH lye, soak at 80°C for desugaring, wash with deionized water until neutral after soaking for 3 hours;

[0041] (2) Break the bacterial cellulose hydrogel block washed to neutral three times with a juice extractor, take the slurry in a beaker with a straw, dilute with deionized water and stir for 0.5h, stir evenly, and obtain a solid content of 1g / The bacterial cellulose aqueous solution of L;

[0042] (3) Take 50ml of the above bacterial cellulose aqueous solution, according to the mass volume ratio of organic acid to bacterial cellulose aqueous solution is 0.02:1g / ml, add 1.0g malic acid, then place it in a magnetic stirrer and stir evenly, add 0.5g chitosan Sugar (-COOH in malic acid and -NH in chitosan 2 The mol ratio is 5:1), and continued stirring for 12h to obtain a mixed sol;

[0043] (4) draw the mixed sol in step (3) with a syringe, add dropwise in the petri dish that 1mol / LNaOH solution is housed, sti...

Embodiment 2

[0051] (1) Put the bacterial cellulose hydrogel in 3mol / L NaOH lye, soak at 90°C for desugaring, wash with deionized water until neutral after soaking for 1 hour;

[0052] (2) Break the bacterial cellulose hydrogel block washed to neutral three times with a juice extractor, take the slurry in a beaker with a straw, dilute with deionized water and stir for 0.5h, stir evenly, and obtain a solid content of 1g / The bacterial cellulose aqueous solution of L;

[0053] (3) Take 50ml of the above-mentioned bacterial cellulose aqueous solution, according to the mass volume ratio of organic acid and bacterial cellulose aqueous solution is 0.024:1g / ml, add 1.2g of malic acid, then put it in a stirrer and stir evenly, add 0.5g of chitosan (-COOH in malic acid and -NH in chitosan 2 The mol ratio is 6:1), and continued stirring for 18h to obtain a mixed sol;

[0054] (4) draw the mixed sol in step (3) with a syringe, add dropwise in the petri dish that 2mol / LNaOH solution is housed, stir ...

Embodiment 3

[0059] (1) Put the bacterial cellulose hydrogel in 4mol / L NaOH lye, soak at 70°C for desugaring, wash with deionized water until neutral after soaking for 5 hours;

[0060] (2) Break the bacterial cellulose hydrogel block washed to neutral three times with a juice extractor, take the slurry in a beaker with a straw, dilute with deionized water and stir for 0.5h, stir evenly, and obtain a solid content of 1g / The bacterial cellulose aqueous solution of L;

[0061] (3) Take 50ml of the bacterial cellulose aqueous solution mentioned above, according to the mass volume ratio of the organic acid to the bacterial cellulose aqueous solution is 0.03:1g / ml, add 1.5g of malic acid, stir on a magnetic stirrer until completely dissolved, then add 0.5g Chitosan (-COOH in malic acid and -NH in chitosan 2 Molar ratio is 7:1), continuous stirring 24h, obtain mixed sol;

[0062] (4) draw the mixed sol in step (3) with a syringe, add dropwise in the petri dish that 3mol / LNaOH solution is hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com