Method for preparing heavy metal adsorbent from waste polyvinyl chloride plastics

A technology for waste polyvinyl chloride and polyvinyl chloride, which is applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., and can solve the problems of poor recycling of waste polyvinyl chloride plastics, etc. , to achieve the effect of increasing the recycling effect and increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

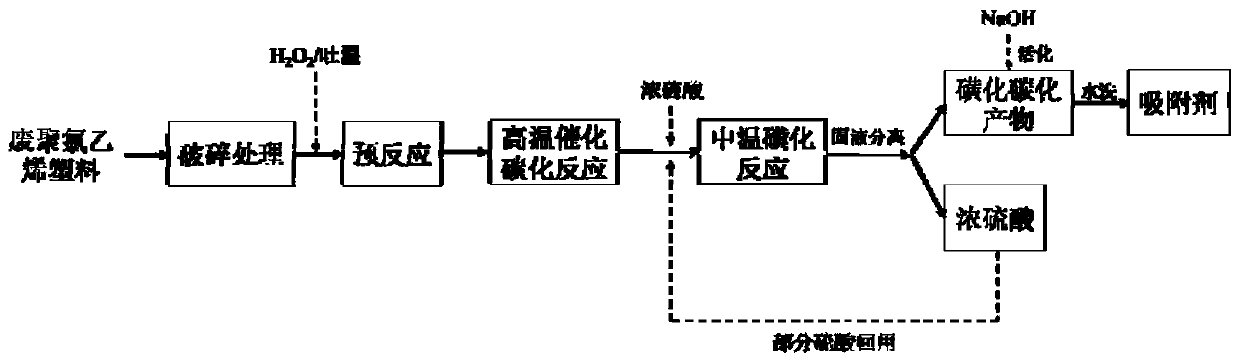

Image

Examples

Embodiment 1

[0028] A kind of method utilizing waste polyvinyl chloride plastics to prepare heavy metal adsorbent:

[0029] (1) Take waste and old polyvinyl chloride plastics (waste plastic pipes, waste plastic bottles, etc.) and crush them to 60 mesh through a crusher. Weigh 12g of broken plastic and place it in a high-temperature reactor, and add 32% H 2 o 2 Mix 50mL with liquid Tween, the mass ratio is 1:0.1; Stir at 35°C at a speed of 80r / min for a pre-reaction for 20min. After the crushed plastic and the catalyst are fully mixed, close the reactor. Set the temperature of the oven at 220°C to continue the catalytic reaction for 5 hours. After the reaction time is up, take the high-temperature reactor out of the oven and cool it down to room temperature naturally;

[0030] (2) performing solid-liquid separation on the mixture in the reactor to obtain a hydrothermal carbonization product. Weigh 5 g of the hydrothermal carbonization product into the reactor, and add 40 mL of 98% concen...

Embodiment 2

[0033] A kind of method utilizing waste polyvinyl chloride plastics to prepare heavy metal adsorbent:

[0034] (1) Take waste and old polyvinyl chloride plastics (waste plastic pipes, waste plastic bottles, etc.) and crush them to 100 mesh through a crusher. Weigh 15g of broken plastic and place it in a high-temperature reaction kettle, and add 32% H 2 o 2 Mix 45mL with Tween in a liquid state, the mass ratio is 1:0.25; Stir at a temperature of 35°C at a speed of 110r / min for a pre-reaction for 15min. After the crushed plastic and the catalyst are fully mixed, close the reactor. Set the temperature of the oven at 210°C to continue the catalytic reaction for 6 hours. After the reaction time is up, take the high-temperature reactor out of the oven and cool it down to room temperature naturally;

[0035] (2) performing solid-liquid separation on the mixture in the reactor to obtain a hydrothermal carbonization product. Weigh 8 g of hydrothermal carbonization product into the r...

Embodiment 3

[0038] A kind of method utilizing waste polyvinyl chloride plastics to prepare heavy metal adsorbent:

[0039] (1) Take waste and old polyvinyl chloride plastics (waste plastic pipes, waste plastic bottles, etc.) and crush them to 80 meshes through a crusher. Weigh 10 g of broken plastic and place it in a high-temperature reaction kettle, and add 32% H 2 o 2Mix 45mL with Tween in a liquid state, the mass ratio is 1:0.15; Stir at a temperature of 40°C at a speed of 65r / min for a pre-reaction for 10min. After the crushed plastic and the catalyst are fully mixed, close the reactor. Set the temperature of the oven at 240°C to continue the catalytic reaction for 3 hours. After the reaction time is up, take the high-temperature reactor out of the oven and cool it down to room temperature naturally;

[0040] (2) performing solid-liquid separation on the mixture in the reactor to obtain a hydrothermal carbonization product. Weigh 5 g of the hydrothermal carbonization product into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com