A linear-crosslinked multi-component copolymerized polyamide reverse osmosis membrane for seawater desalination and its preparation method

A technology of copolyamide and multi-component copolymerization, which is applied in the field of linear-crosslinked multi-component copolyamide reverse osmosis membrane and its preparation for seawater desalination, and can solve the problem of large intermolecular free volume, no breakthrough development, chlorine Sodium chloride rejection rate is small, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

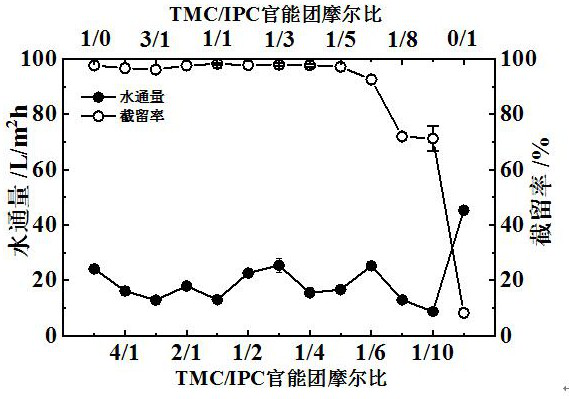

[0036]Example 1: The organic phase solution used in the experimental interface polymerization was used as a different proportion of the n-hexane solution of a xylophenylel chloride and a diacyl chloride monomer. The MPD / TMC polyamide reverse osmosis composite film was prepared, and the mass ratio of the TMC concentration of 0.1 wt%, MPD and TMC was 20: 1, and the molar ratio of the amine group and the acyl chloride group was calculated from 33: 1. The interface reaction time is 60 seconds, and the temperature range of interface polymerization is 25 degrees Celsius. The molar ratio of the remodeling of the amine group and the acid chloride group is unchanged, and the ratio of TMC and diacyl chloride monomers occupy an acid function group. As an organic phase monomer as an organic phase monomer, TMC and IPC has a molar ratio of 1: 0, 4: 1, 3: 1, 2: 1, 1: 1: 0, 4: 1, 3: 1, 2: 1, 1: 1, 1: 2, 1: 3, 1: 4, 1: 5, 1: 6, 1: 8, 1: 10, 0: 1, as shown in the following table.

[0037]Table 1 xylop...

example 2

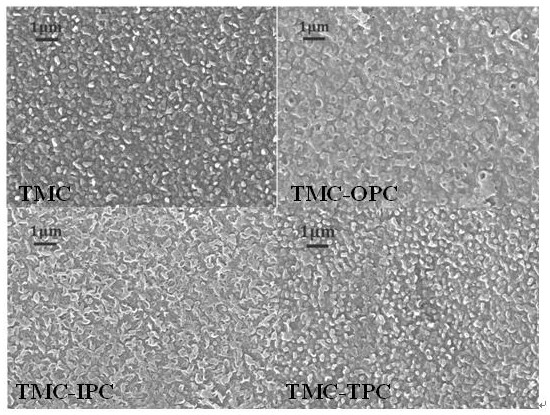

[0046]Example 2: Trial chloride, xylophenyl chloride, and phthal chloride, a reverse osmosis membrane surface prepared by benen dikylel chloride. For pure benzophenylel chloride, the particulate structure and "blade" structure are commonly present, and the overall structure is integrated; for the phenylethyl chloride and the amphimethyl chloride sample, "blade" shaped structure Structure, exhibiting "peak-wave valley" rough morphology; xylophenyl trimethyl chloride and the structure of the adjacent xylel chloride, and the surface forms a projection, and there is a recess or a pore structure in the protruding portion; Trimethyl chloride and the terephthal chloride sample, the "leaf-shaped" structure is significantly reduced, and a zero-fraud is dense distribution.

example 3

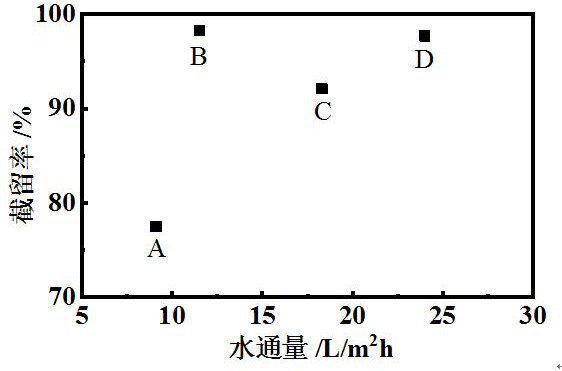

[0047]Example III: Since the substrate has a large impact on the separation performance of the obtained reverse osmosis membrane, the selection of the substrate is first selected, and the US020, the electrospun film, the imported PS20 and the domestic PS20 are compared. Among them, the average pore diameter of the microfiltration electrospun film is 0.5 microns; the an average aperture of the ultrafiltration membrane is 25 nm. MPD / TMC reverse osmosis membrane was prepared by using different substrates to polymerize the interface polymerization in Example No. 1. Studies have shown that the substrate PS20 is optimal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com