Oyster mushroom fermentation material feeding and inoculating integrated synchronous equipment and operation method

A technology for synchronizing equipment and fermented materials, applied in the fields of botany equipment and methods, agriculture, mushroom cultivation, etc., can solve problems such as automatic operation, mechanical fuzzy operation, and inadequate opening of bags, and achieve reliability and work stability. Strong performance, changing the production mode, and completing the job accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

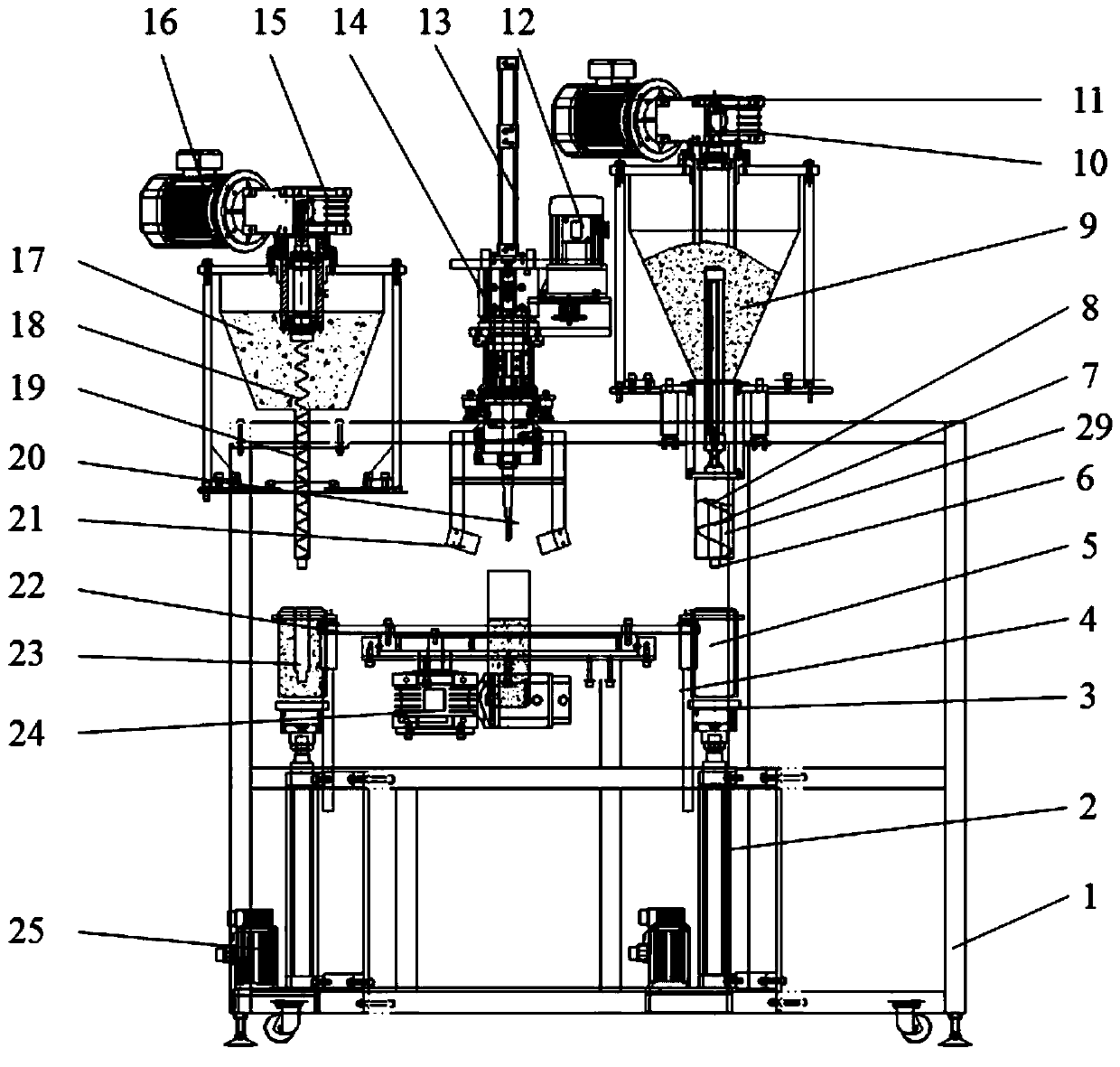

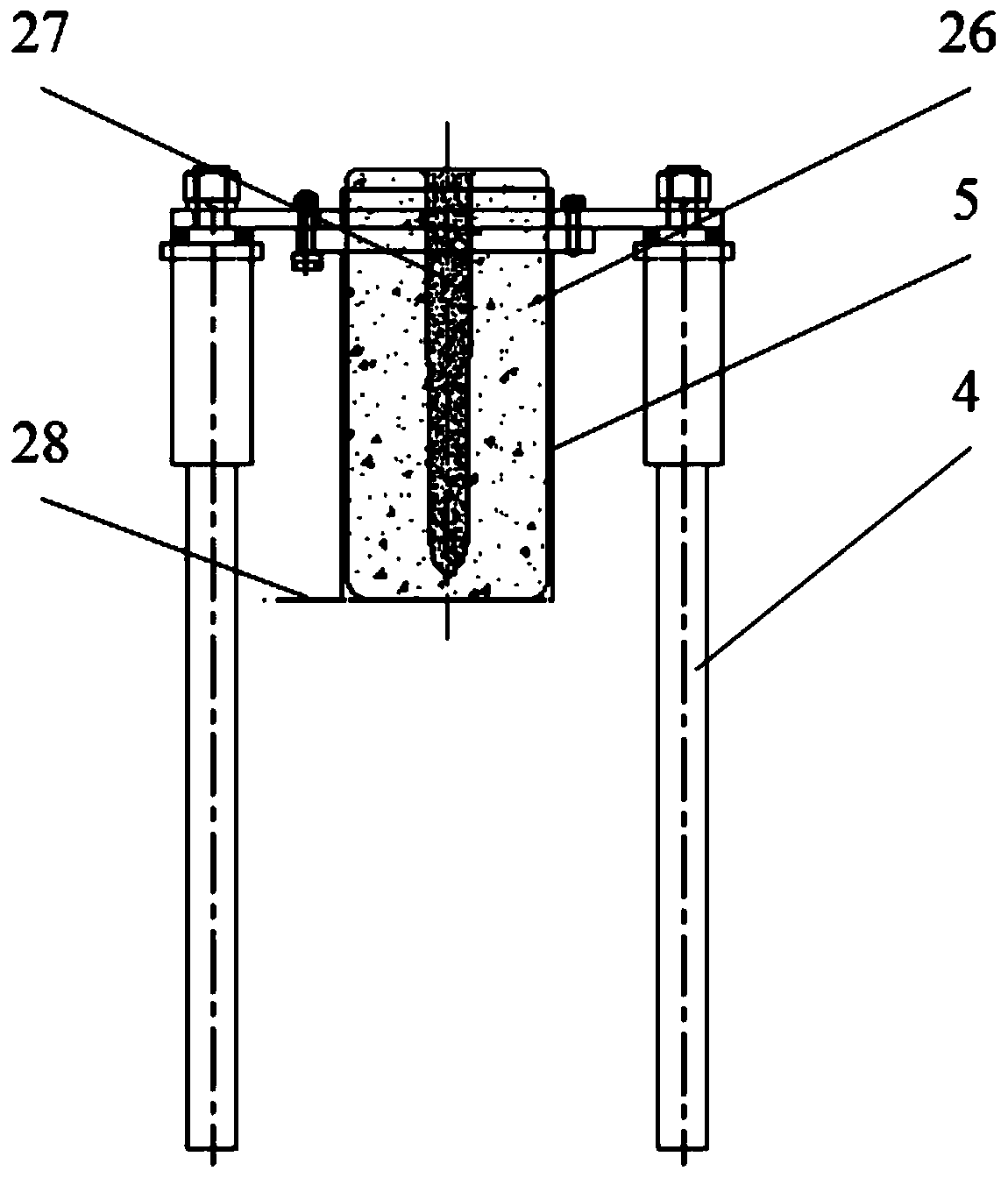

[0036] The Pleurotus ostreatus fermented material charging inoculation integrated synchronous equipment that present embodiment provides, as Figure 1-5 Shown: It includes at least the host computer, S7-1200 PLC control cabinet, TPC1061 touch screen, frame 1 and the turntable device installed on the frame, the charging device, the socket device, the inoculation device and the bag output device. in:

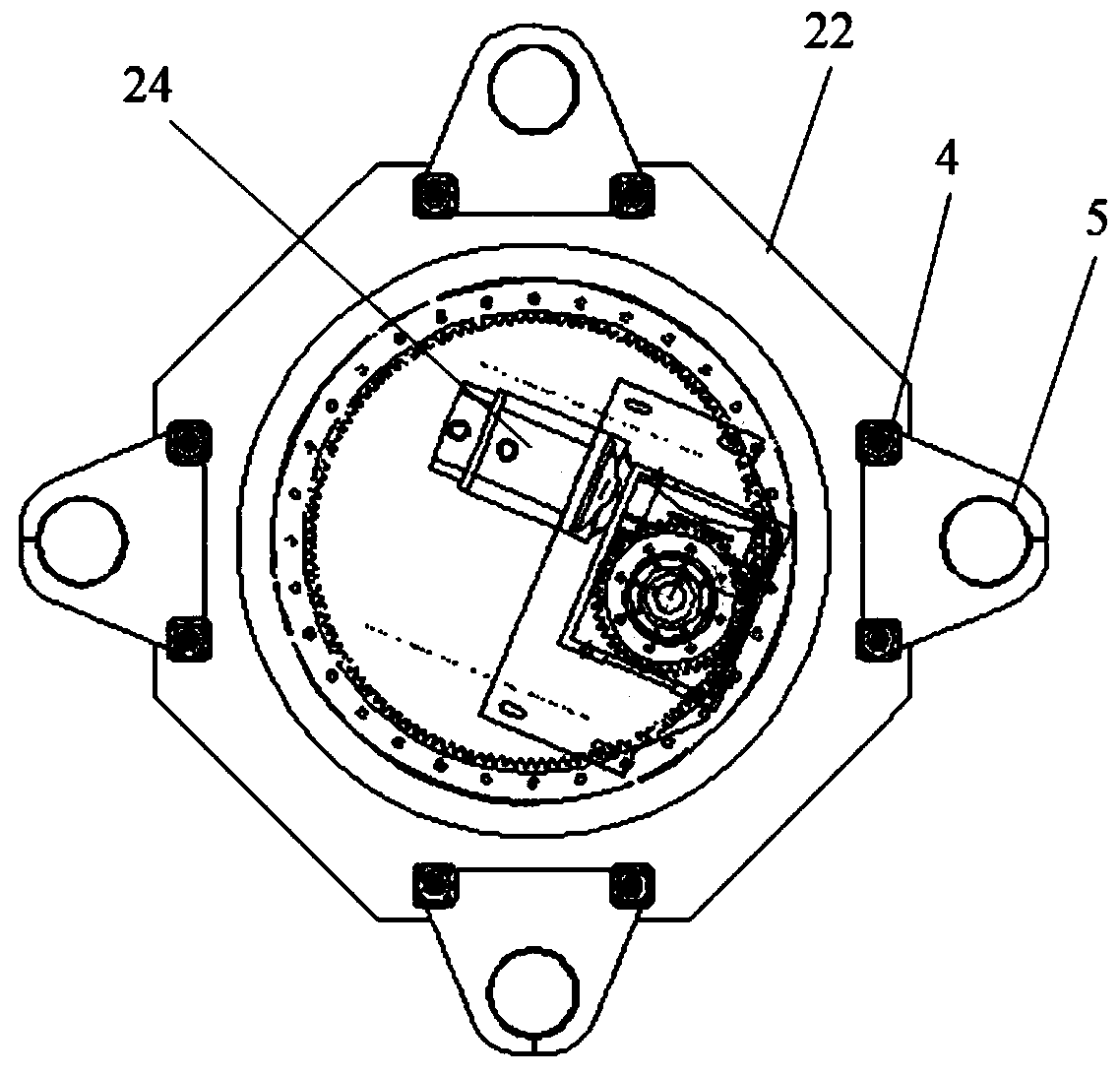

[0037] Described turntable device comprises turntable motor 24 and hollow turntable 22, and described turntable motor 24 is installed on the frame, and the output shaft of turntable motor 24 is connected with driving pinion through coupling, and on the inner ring of described hollow turntable 22 A driven bull gear is fixedly installed, and the driving pinion and the driven bull gear mesh to realize the rotation control of the hollow turntable 22 under the power transmission of the turntable motor 24 .

[0038] The outer circle of the hollow turntable has four stations distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com