Method for thinning solid-body layers provided with components

A solid layer, solid technology, used in electrical components, welding equipment, semiconductor devices, etc., can solve the problems of no longer force transmission, poor polymer adhesion, etc., to avoid material loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0162] Figure 1a The provision of a solid 1 (in particular a wafer) is shown.

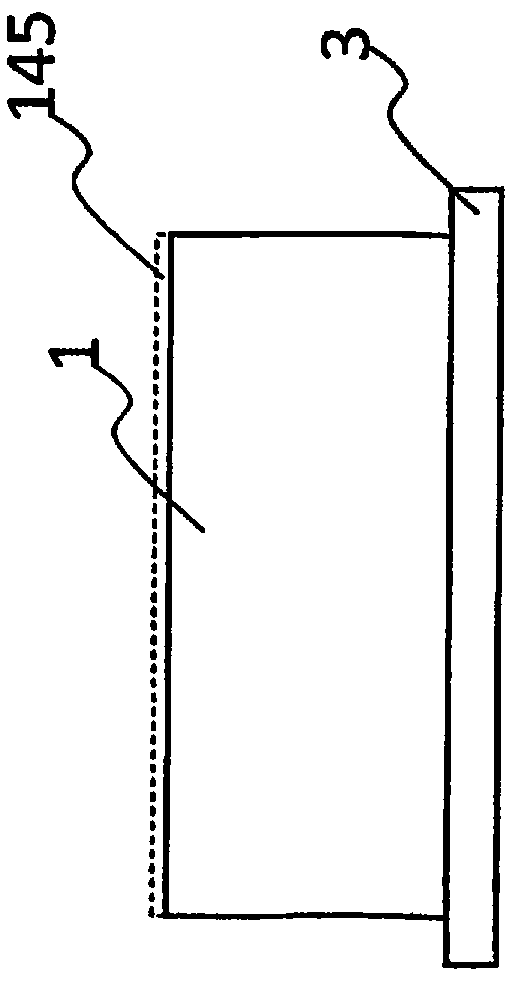

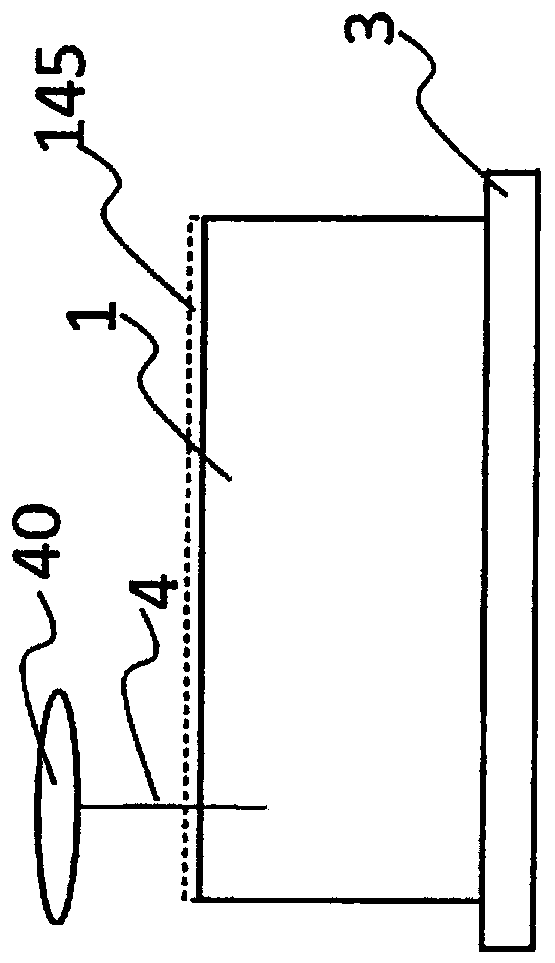

[0163] according to Figure 1b, the provided solid body 1 is coupled or glued or welded or screwed or clamped on a tool carrier (chuck) 3 , wherein the tool carrier preferably includes a cooling function and thus preferably forms a cooling device 3 . The solid body 1 is preferably fastened, in particular glued, to the cooling device 3 longitudinally with its underside, which is preferably longitudinally opposite the surface 5 . In order to produce modification 9 , a laser beam is therefore introduced into solid 1 via surface 5 , which is a constituent of the solid layer to be separated, in the direction of cooling device 3 . Furthermore, it is particularly preferred to subject surface 5 to a high-temperature treatment, in particular to arrange an epitaxial material on solid surface 5 , whereby a further layer 145 or a plurality of further layers 145 are preferably obtained. The at least one high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com