A high power density two-speed electric drive device for tracked vehicles with integrated design

A high power density, electric drive technology, applied in electromechanical devices, electric components, control devices, etc., can solve the problems of inability to meet the mobility requirements of large-tonnage vehicles, low overall power density, and disordered electrical wiring harnesses, to improve the highest working efficiency. The effect of rotating speed, simple structure and small space occupation of power compartment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] With reference to the accompanying drawings, the present invention is implemented as follows:

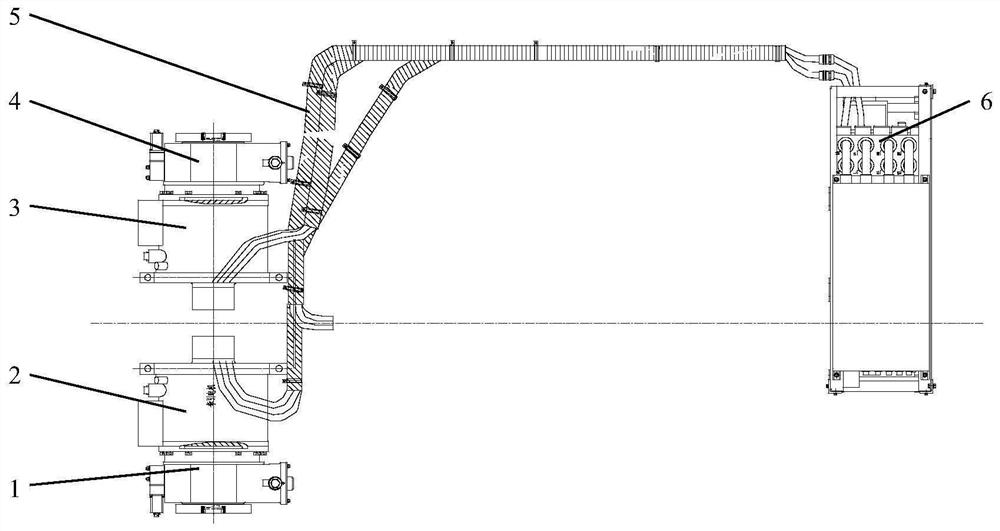

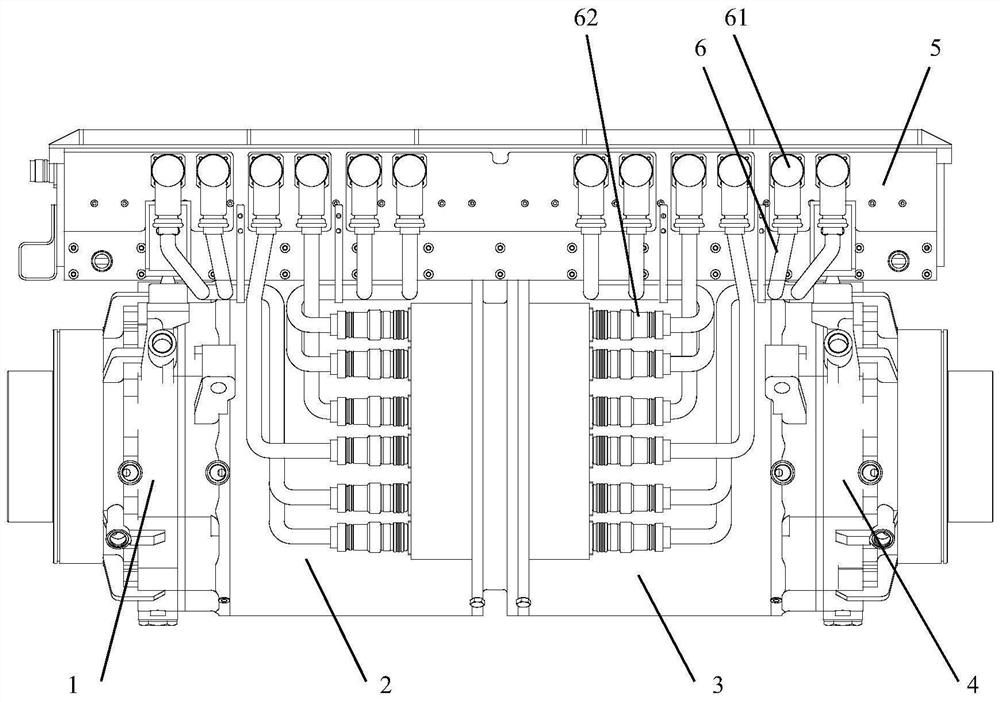

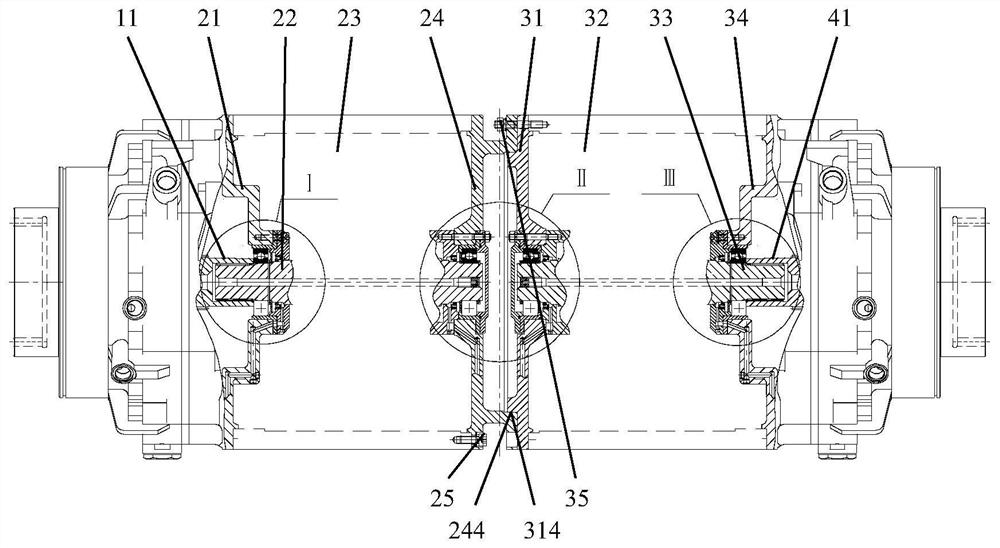

[0035]An integrated design high power density two-speed electric drive device for tracked vehicles, the present invention consists of a left two-speed transmission 1, a left driving motor 2, a right driving motor 3, a right two-speed transmission 4, and a driving motor controller 5. The high-voltage wiring harness is composed of 6. The left two-speed transmission 1, the left driving motor 2, the right driving motor 3, and the right two-speed transmission 4 are coaxially arranged, and the driving motor controller 5 is installed on the left two-speed transmission 1 and the right two-speed transmission 4. Above; the left two-speed transmission 1 and the right two-speed transmission 4 are symmetrical in structure; the power interface of the left drive motor 2, the power interface of the right drive motor 3 and the corresponding power interface of the drive motor controller 5 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com