New energy automobile speed reducer driven gear and manufacturing process thereof

A technology of new energy vehicles and driven gears, applied in belts/chains/gears, mechanical equipment, components with teeth, etc., can solve problems such as low material utilization, high processing costs, and long production cycles, and achieve material High utilization rate, meet supporting requirements, and improve tooth surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

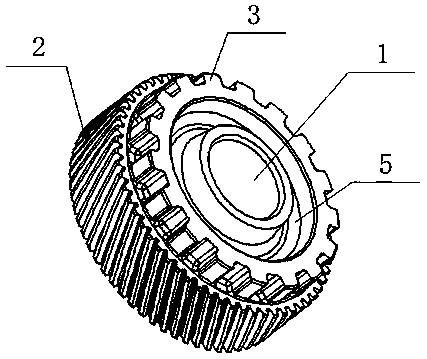

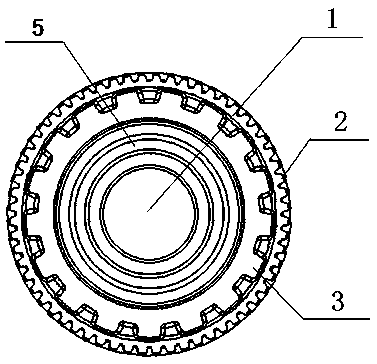

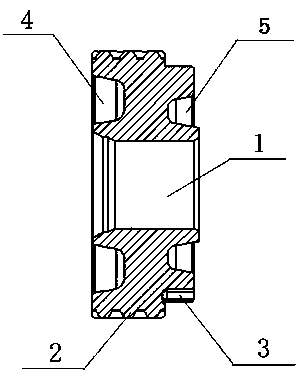

[0015] Example: see figure 1 , figure 2 with image 3 As shown, the driven gear of a new energy vehicle reducer has a hollow cylindrical structure and is forged from metal. It is provided with a center hole 1, and its outer circumferential surface is provided with helical teeth 2 and straight teeth 3, respectively. Each end surface is provided with an annular groove, the end surface adjacent to the helical tooth 2 is provided with a first annular groove 4, and the end surface adjacent to the straight tooth 3 is provided with a second annular groove 5.

[0016] The manufacturing process includes the following steps: ① blanking: cutting the required metal bar; ② heating upsetting: heating to 1090 ℃-1150 ℃ coating upsetting extrusion; ③ extrusion molding: the upsetting of the above-mentioned upsetting by a die The blank is extruded to form the first annular groove 4, the second annular groove 5 on both ends, the straight teeth 3 on the outer circumferential surface, and the central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com