A method for culturing Chlorella pyrenoidosa with high biomass and high protein content

A technology of high biomass of chlorella pyrenoidosa, applied in the biological field, can solve the problems of high production cost of chlorella pyrenoidosa, and achieve the effects of high market competitiveness, high biomass and high protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

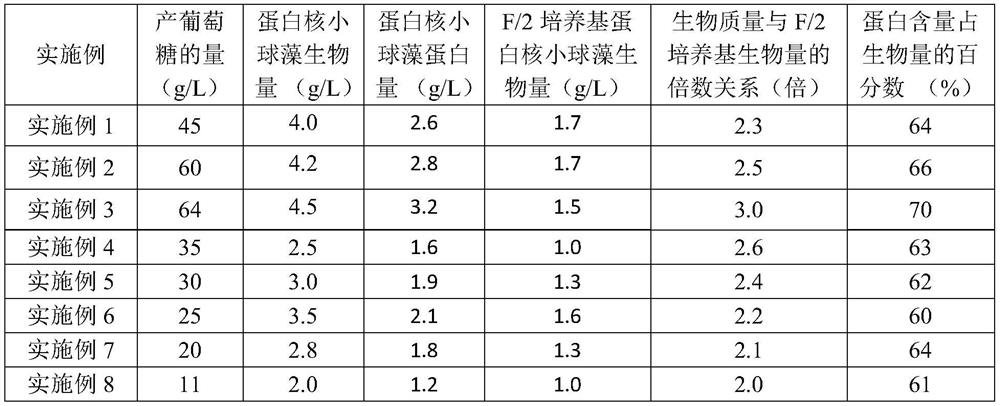

Embodiment 1

[0023] A method for cultivating Chlorella pyrenoidosa with low cost, high biomass and high protein content, comprising the following steps:

[0024](1) Activation of Clostridium thermocellum strains: Inoculate 100ul of β-1,4-glucosidase into the recombinant strain of Clostridium thermocellum DSM 1313 cellulite into 4ml of anaerobic fermentation medium, activate at 50°C After 18 hours, it was directly used as a saccharification strain after reactivation. The composition of the anaerobic fermentation medium is: dipotassium hydrogen phosphate 2.9g / L, potassium dihydrogen phosphate 1.5g / L, urea 2.1g / L, calcium chloride 0.1g / L, magnesium chloride 1.8g / L, sulfuric acid Ferrous 0.0005g / L, sodium sulfide 2g / L, corn steep liquor 4g / L, trisodium citrate 2g / L, pH 6.5-7.5.

[0025] (2) Straw saccharification: transfer the pretreated straw to the anaerobic fermentation system, add medium according to the solid-to-liquid mass ratio of 1:10, add an appropriate amount of the mutagenized stra...

Embodiment 2

[0033] Different from Example 1, a method for cultivating Chlorella pyrenoidosa with low cost, high biomass and high protein content comprises the following steps:

[0034] (1) Activation of Clostridium thermocellum strain: Inoculate 150ul of β-1,4-glucosidase into the recombinant strain of Clostridium thermocellum DSM 1313 cellulite into 4ml of anaerobic fermentation medium, activate at 50°C After 18 hours, it was directly used as a saccharification strain after reactivation.

[0035] (2) Straw saccharification: transfer the pretreated straw to the anaerobic fermentation system, add medium according to the solid-to-liquid mass ratio of 1:12, add an appropriate amount of the mutagenized strain obtained in step (1) into the anaerobic fermentation tank, The straw saccharification was carried out at a temperature of 53° C. to obtain a saccharification solution mainly composed of glucose, and the concentration of glucose measured by high performance liquid chromatography reached 6...

Embodiment 3

[0039] Different from Example 1, a method for cultivating Chlorella pyrenoidosa with low cost, high biomass and high protein content comprises the following steps:

[0040] (1) Activation of Clostridium thermocellum strain: Inoculate 120ul of β-1,4-glucosidase into the recombinant strain of Clostridium thermocellum DSM 1313 cellulite into 4ml of anaerobic fermentation medium, activate at 50°C After 18 hours, it was directly used as a saccharification strain after reactivation.

[0041] (2) Straw saccharification: transfer the pretreated straw to the anaerobic fermentation system, add medium according to the solid-to-liquid mass ratio of 1:14, add an appropriate amount of the mutagenized strain obtained in step (1) into the anaerobic fermentation tank, Saccharification of straw was carried out at a temperature of 55°C to obtain a saccharification solution mainly composed of glucose, and the concentration of glucose measured by high performance liquid chromatography reached 64g / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com