Vulcanized natural rubber modified asphalt and preparation method thereof

A natural rubber modification, natural rubber technology, applied in building components, building insulation materials, buildings, etc., to achieve the effect of improving high and low temperature performance, increasing rotational viscosity, and decreasing penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

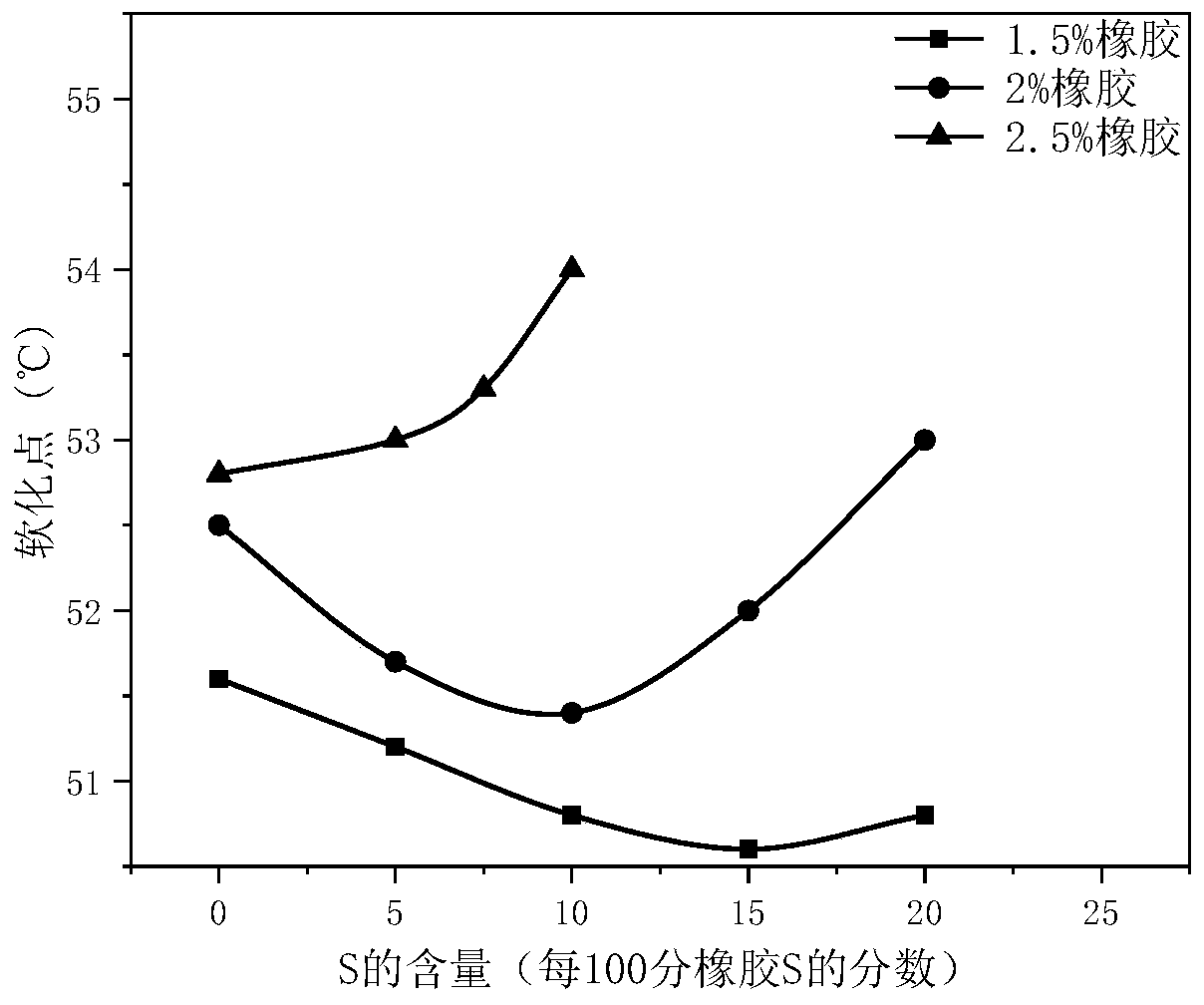

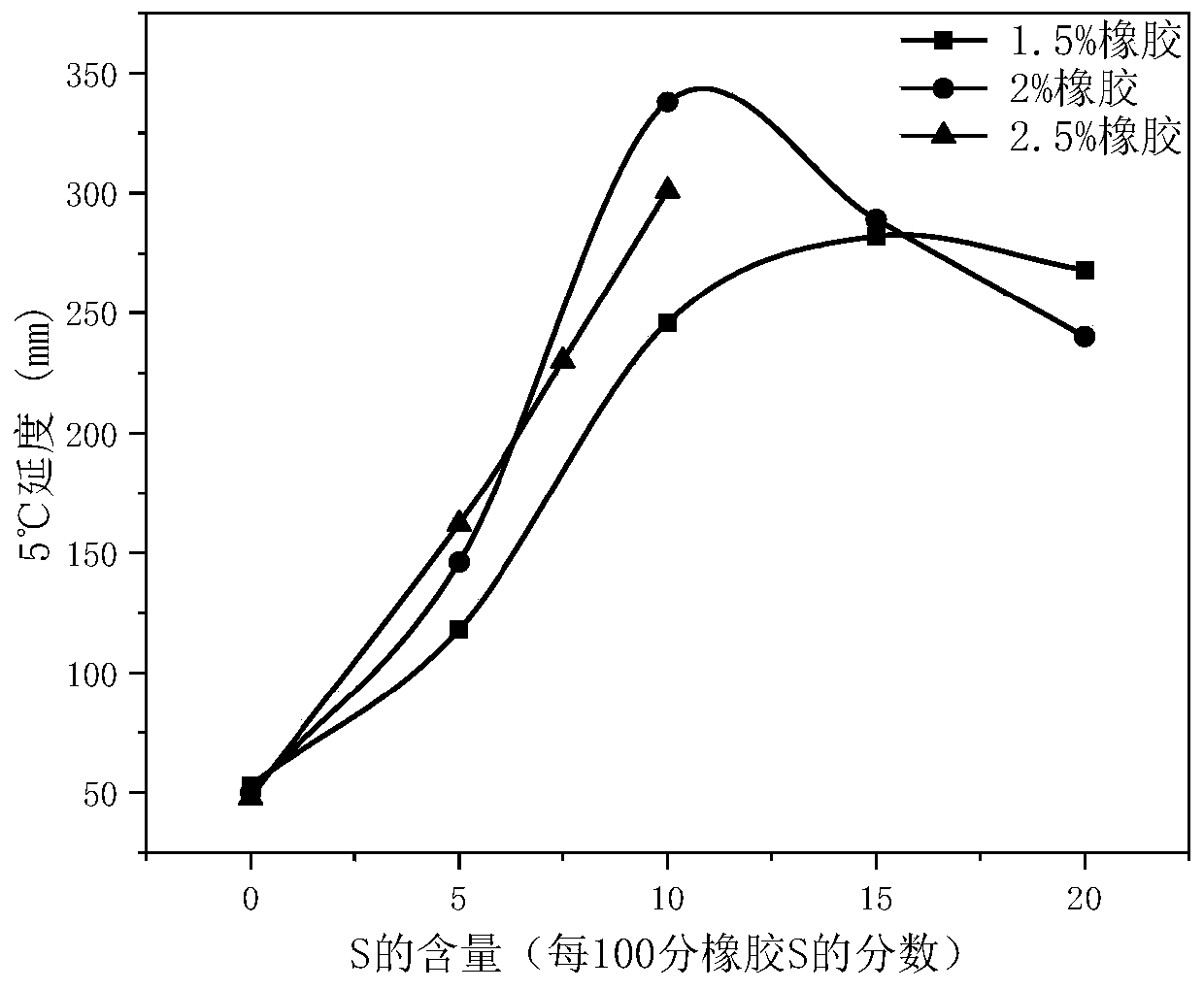

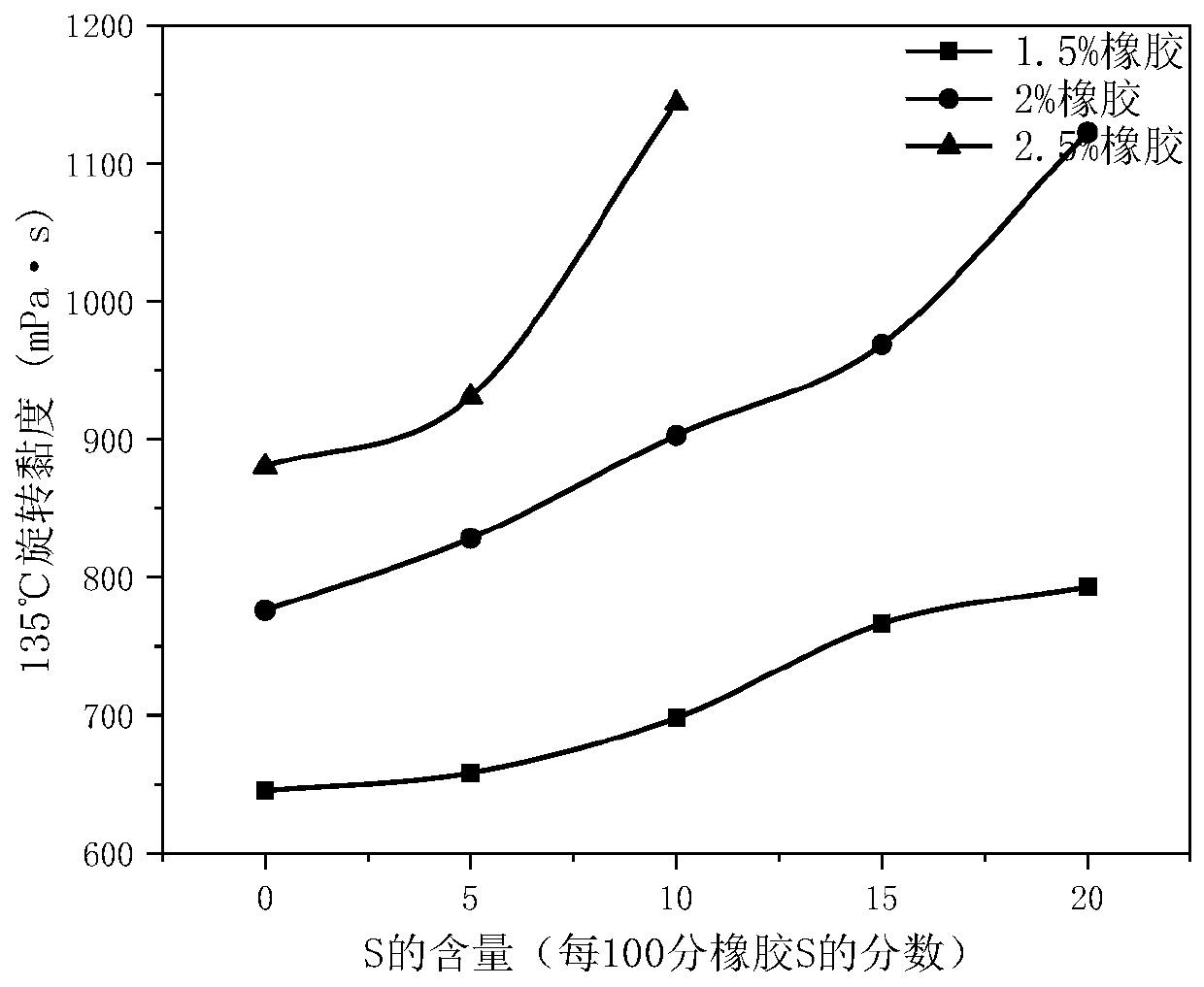

[0024] The mass fraction of natural rubber in the matrix asphalt is 2%, and the vulcanization formula is: 100 parts of natural rubber, 10 parts of sulfur, 5 parts of zinc oxide, 2 parts of stearic acid, and 2 parts of TMTD.

[0025] The specific preparation method is as follows:

[0026] Take 196g of 90# base asphalt, heat and melt at 145°C, add 4g of natural rubber crumbs, stir properly and put it in a 145°C oven for swelling and development for 1 hour; take out the above mixture and rotate and shear it at a high speed at 160°C and 4000rpm for 1 hour , to obtain a natural rubber asphalt mixture in which rubber is evenly dispersed in asphalt; add 0.4g of sulfur, 0.2g of zinc oxide, 0.08g of stearic acid, and 0.08g of TMTD to the mixture according to the vulcanization formula, and continue to rotate and shear at a high speed for 15min according to the above conditions ; Then take it out and put it in an oven at 145°C for 1 hour to keep it warm for 1 hour to obtain the vulcanize...

Embodiment 2

[0028] The mass fraction of natural rubber in the base asphalt is 2.5%, and the vulcanization formula is: 100 parts of natural rubber, 5 parts of sulfur, 5 parts of zinc oxide, 2 parts of stearic acid, and 2 parts of TMTD.

[0029] The specific preparation method is as follows:

[0030] Take 195g of 90# base asphalt, heat and melt at 160°C, add 5g of natural rubber crumbs, stir properly and put it in a 160°C oven to swell and develop for 1.5h; take out the above mixture and rotate and shear at a high speed at 150°C and 6000rpm 1.5h to obtain a natural rubber asphalt mixture in which the rubber is evenly dispersed in the asphalt; add 0.25g of sulfur, 0.25g of zinc oxide, 0.1g of stearic acid, and 0.1g of TMTD to the mixture according to the vulcanization formula, and continue to perform high-speed rotary shearing according to the above conditions. Cut for 30 minutes; then take it out and put it in an oven at 160°C for 2 hours to keep the vulcanized natural rubber modified aspha...

Embodiment 3

[0032] The mass fraction of natural rubber in the matrix asphalt is 2.5%, and the vulcanization formula is: 100 parts of natural rubber, 10 parts of sulfur, 5 parts of zinc oxide, 2 parts of stearic acid, and 2 parts of TMTD.

[0033] The specific preparation method is as follows:

[0034] Take 195g of 90# base asphalt, heat and melt at 140°C, add 5g of natural rubber crumbs, stir properly and put it in a 140°C oven to swell and develop for 1 hour; take out the above mixture at a temperature of 140°C and rotate at a speed of 5000rpm and shear it at a high speed for 1.2 h, to obtain a natural rubber asphalt mixture in which rubber is evenly dispersed in asphalt; add 0.5g of sulfur, 0.25g of zinc oxide, 0.1g of stearic acid, and 0.1g of TMTD to the mixture according to the vulcanization formula, and continue to rotate and shear at a high speed according to the above conditions 20 minutes; then take it out and put it in an oven at 140°C for 1.5 hours to keep the vulcanized natura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com