Automatic stir-frying equipment for kaffir lily fertilizer cannabis sativa seeds

A technology of hemp seeds and Clivia, which is applied in the field of automatic frying equipment for Clivia fertilizer and hemp seeds, can solve the problems of low degree of automation, uneven heating of hemp seeds, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

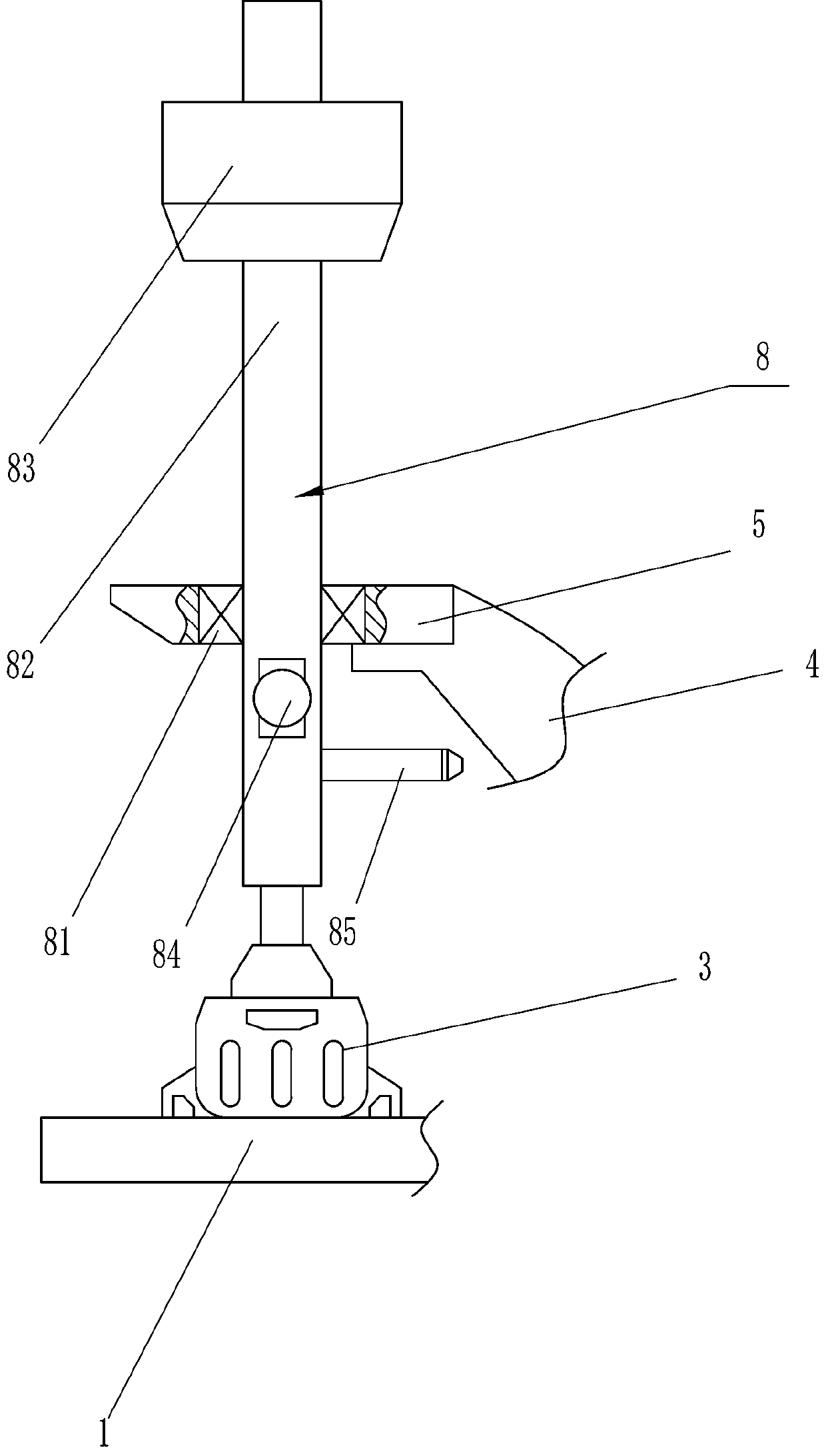

[0022] A kind of Clivia fertilizer hemp seed automatic stir-frying equipment, such as figure 1 As shown, it includes a bottom plate 1, a first support 2, a motor 3, a second support 4, a first support plate 5, a third support 6, a fourth support 7, a power unit 8, a placement device 9, a ring gear 10 and a turning Device 11, specifically:

[0023] Two groups of first supports 2 are connected on the base plate 1, a motor 3 is connected to the right side of the base plate 1, a second support 4 is connected to the right side of the base plate 1, and the second support 4 is located on the motor side. 3 on the right side, the first support plate 5 is connected to the upper side of the second bracket 4, the third bracket 6 is connected to the left side of the bottom plate 1, and the fourth bracket 7 is connected to the upper side of the third bracket 6, so The first support plate 5 is provided with a power device 8, the lower side of the power device 8 is connected to the output sh...

Embodiment 2

[0026] On the basis of Example 1, such as Figure 2-6 As shown, the power device 8 includes a first bearing 81, a first rotating rod 82, a first cam 83, a first connecting rod 84 and a single gear 85, specifically:

[0027] The first support plate 5 is connected with a first bearing 81, and the first bearing 81 is connected with a first rotating rod 82, and the upper side of the first rotating rod 82 is connected with a first cam 83, and the first rotating rod 82 is connected with a first cam 83. The cam 83 can be in contact with the turning device 11 , and the first rotating rod 82 is connected with a first connecting rod 84 at a position below the first bearing 81 , and the first connecting rod 84 can be in contact with the placing device 9 , A single gear 85 is connected to the lower side of the first rotating rod 82 , and the single gear 85 can mesh with the ring gear 10 .

[0028]After the motor 3 is started, the motor 3 will drive the first rotating rod 82 to rotate, an...

Embodiment 3

[0039] On the basis of Example 2, such as Figure 6 As shown, a smoke exhaust device 12 is also included, the fourth bracket 7 is provided with a smoke exhaust device 12, the smoke exhaust device 12 is located above the round bottom pot 99, and the smoke exhaust device 12 includes a housing 121. The fourth support plate 122, the third bearing 123, the second rotating rod 124, the fan blade 125, the belt drive assembly 126 and the ventilation pipe 127, specifically:

[0040] The upper side of the fourth bracket 7 is connected with a housing 121, the upper side of the housing 121 is connected with a fourth support plate 122, and the fourth support plate 122 is connected with a third bearing 123, and the third bearing 123 is connected with a second rotating rod 124, the lower side of the second rotating rod 124 is connected with the fan blade 125, and the belt transmission assembly 126 is connected between the second rotating rod 124 and the upper side of the first rotating rod 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com