Method for processing kitchen waste and equipment thereof

A technology of kitchen waste and treatment equipment, which is applied in the direction of combustion method, separation method, lighting and heating equipment, etc., can solve people's health hazards, environmental pollution and other problems, and achieve the effect of simple operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Provide the best embodiment of the present invention below in conjunction with accompanying drawing.

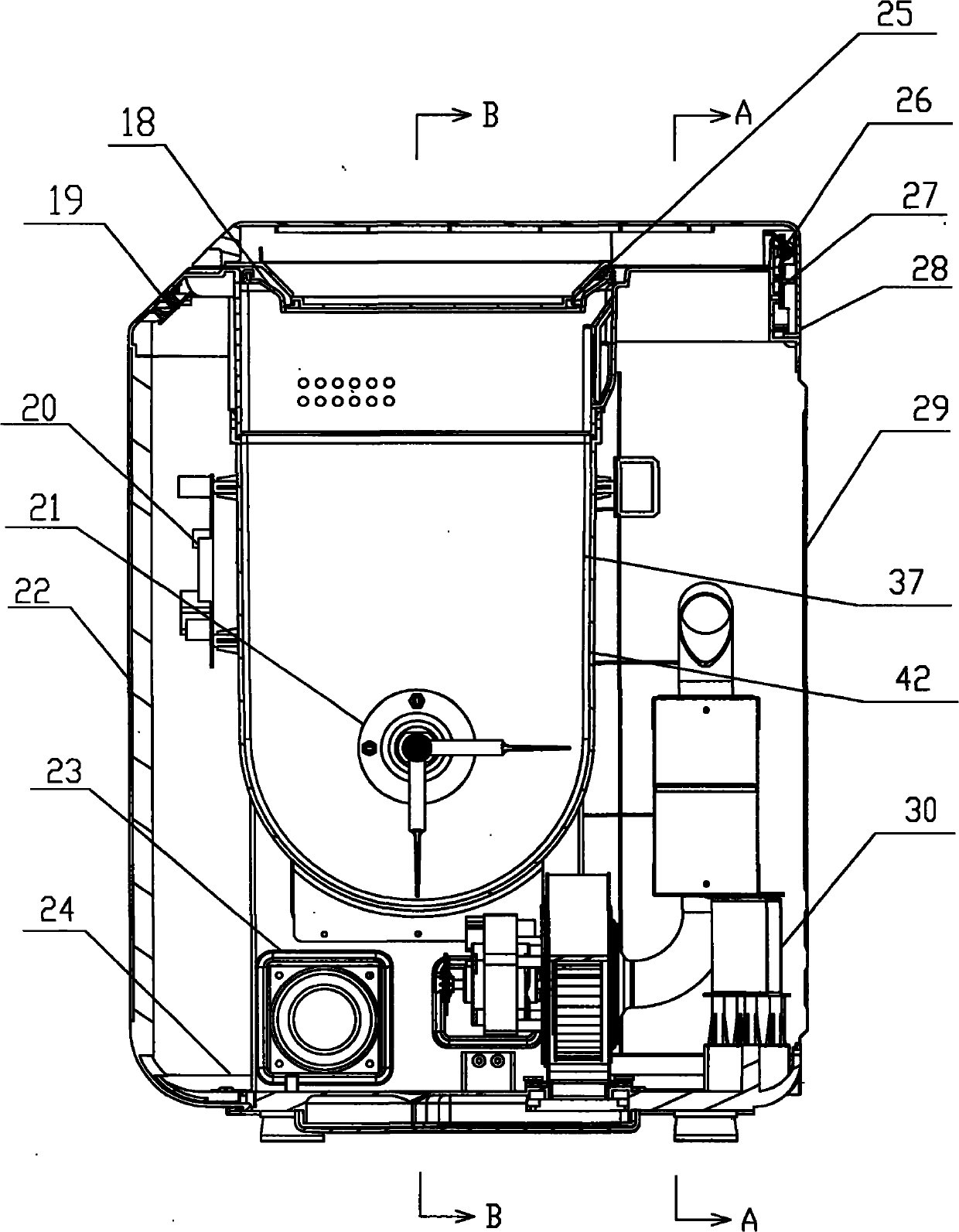

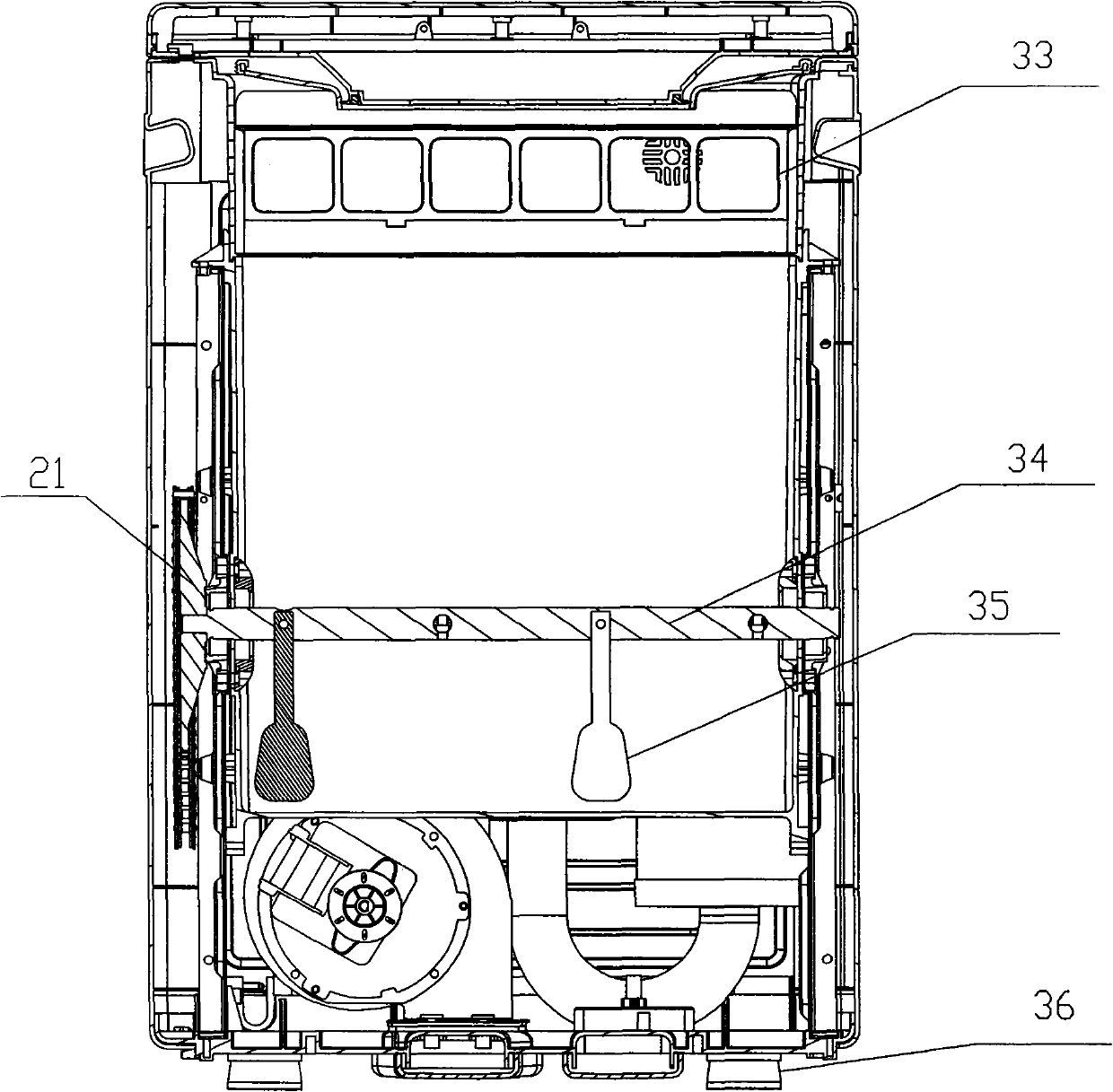

[0031] The embodiment of the present invention relates to a kitchen waste treatment method and its equipment, the specific structure of which equipment is: a kitchen waste treatment equipment, such as figure 1 , figure 2 As shown, a housing is formed by cover assembly 1, front shell 22, left side plate 6, right side plate 17, rear cover plate 29 and base 24; The pin is hinged on the back cover, and the pin is fixed with the shaft support plate 27 located on the back cover. A mixing tank 37 is installed in the housing, a middle seat 2 is provided between the mixing tank and the charging cover, the middle seat and the middle seat rear cover 28 are fixed on the rear cover, and the bottom edge ring of the charging cover is provided with a sealing strip 25 and the middle The seat is matched with each other, and the mixing tank and the feeding cover are sealed with a seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com