Anti-slot-disorder hoisting machine special for railway track laying

A technology of hoisting machinery and hoisting mechanism, which is applied in the field of special hoisting machinery for track laying. It can solve problems such as blockage of pulleys, abnormal noise or wear of wire ropes, and insufficient technology, so as to avoid chaotic grooves, abnormal noise or wear and stuck effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

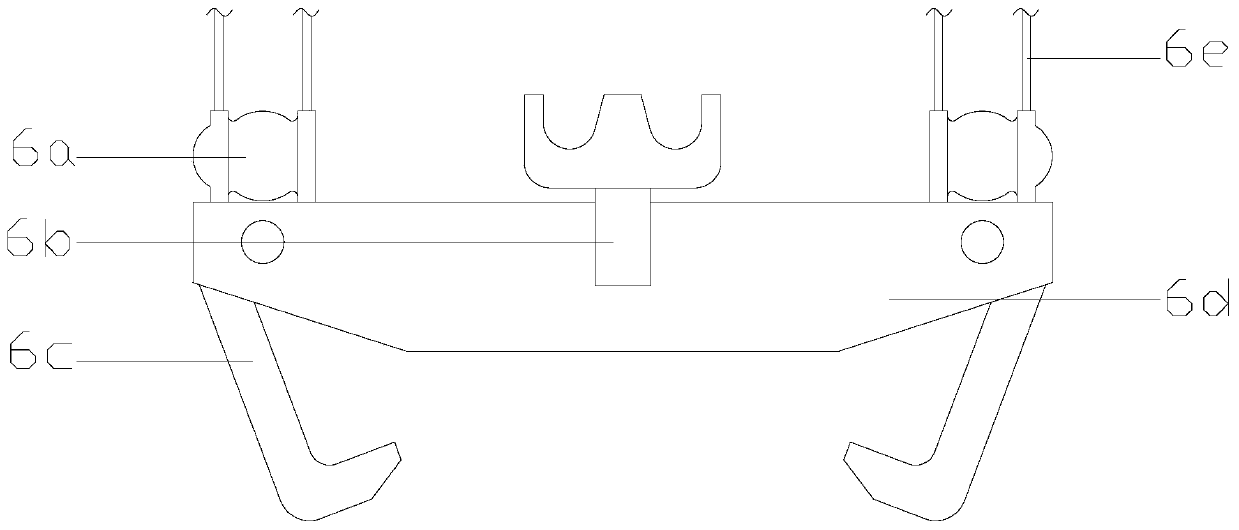

[0024] see Figure 1-Figure 5, the present invention provides a special hoisting machine for track laying of anti-disorder grooves, its structure includes a support beam frame 1, a control panel 2, a cable coiler 3, a traveling mechanism 4, a telescopic hydraulic cylinder 5, and a sleeper lifting mechanism 6. The traveling mechanism 4 is installed vertically and is close to the preset track. The control panel 2 is fixed above the left traveling mechanism 4 by bolts. The cable take-up disk 3 is located on the left side of the control panel 2. The beam frame 1 is an inverted U-shaped structure and is fixed together with the top of the traveling mechanism 4 by bolts. The telescopic hydraulic cylinders 5 are provided with four and installed around the front of the supporting beam frame 1 respectively. The sleeper lifting mechanism 6 is located on the support In the middle of the beam frame 1, the sleeper lifting mechanism 6 is composed of a steel rope tightener 6a, a lifting limit...

Embodiment 2

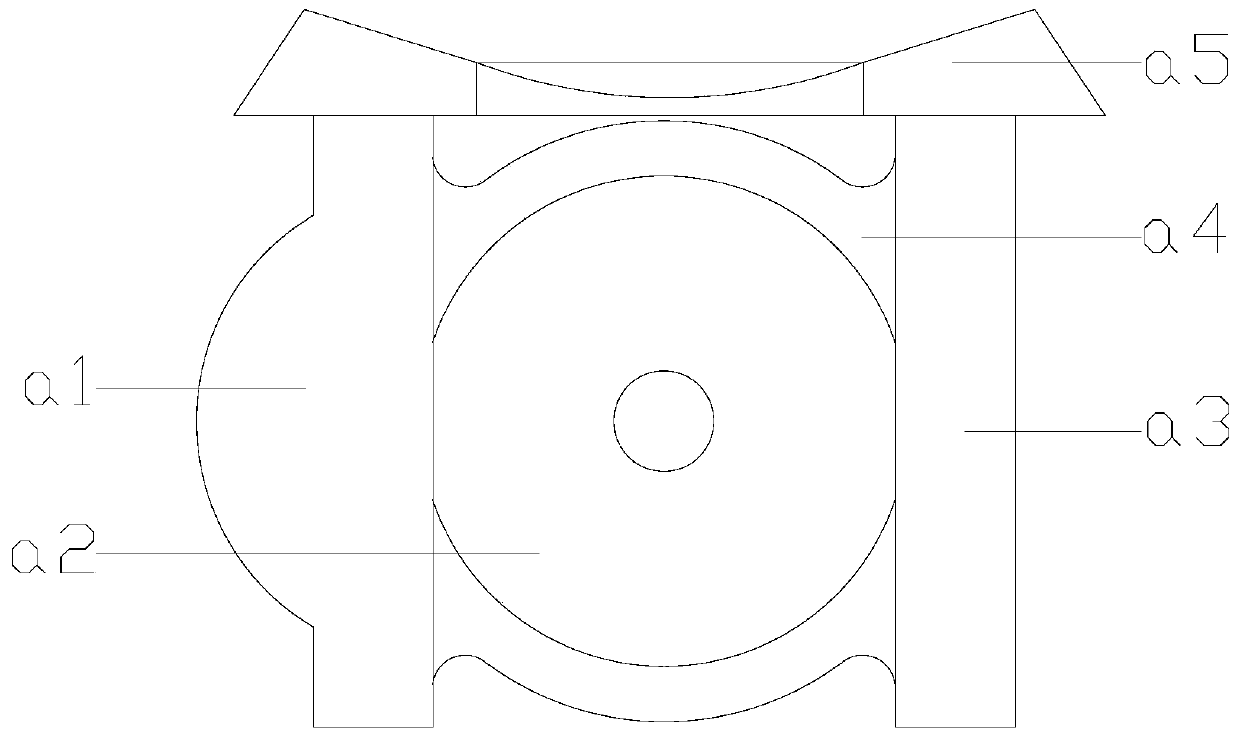

[0027] see Figure 6-Figure 7 , the steel rope cleaning device a5 is composed of a gravel remover a51, a cleaner fixing column a52, and a gravel storage tank a53. buckle, the sand remover a51 is provided with two and located above the cleaner fixing column a52, the sand storage tank a53 is installed in the middle of the sand remover a51, and the sand remover a51 is inclined to the middle arranged in shape. The sand remover a51 is composed of a remover bracket 511, a transmission wheel 512, a rope drive wheel 513, a fixed support 514, and a steel rope brush 515. The remover bracket 511 adopts a right-angle trapezoidal structure and is installed on the cleaner to Above the column a52, the fixed support 514 is nested in the middle of the bottom of the remover bracket 511, the rope drive wheel 513 is installed in the middle of the fixed support 514 and interlocked with each other, and the steel rope brush 515 is installed on the fixed On the top of the support 514, the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com