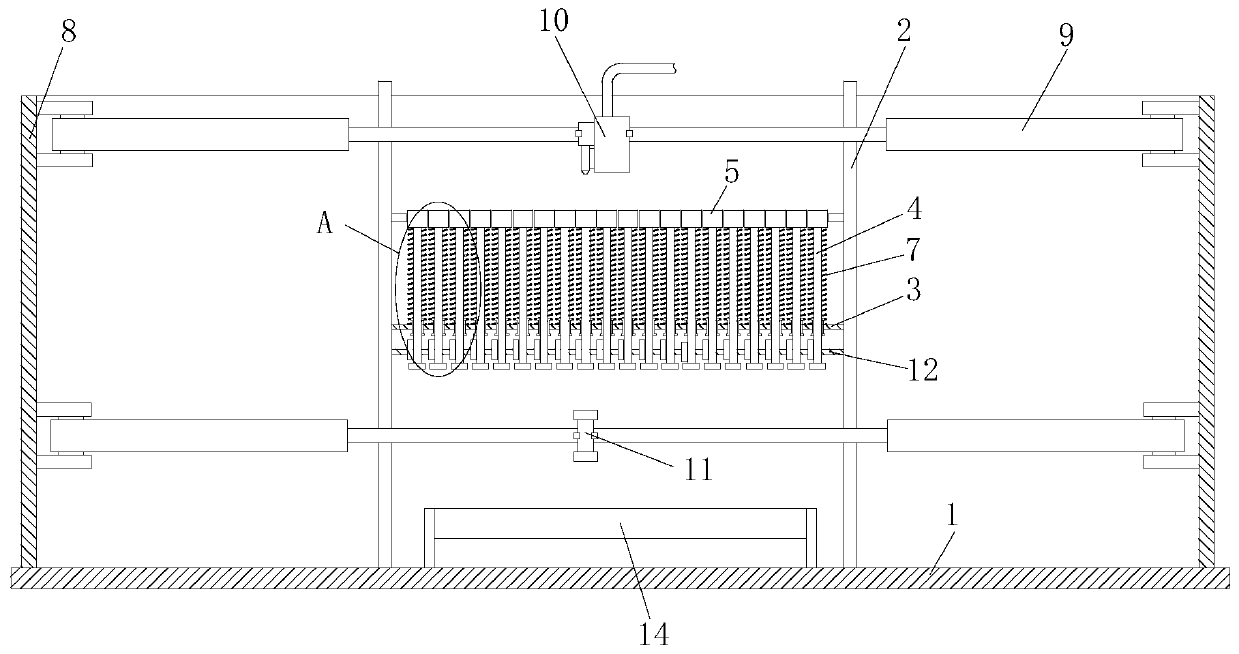

Laser cutting platform

A laser cutting, laser cutting machine technology, applied in laser welding equipment, welding/cutting auxiliary equipment, auxiliary welding equipment, etc., can solve the problem that the steel plate cannot be well supported, the steel plate cannot be effectively fixed, and is prone to offset and other problems, to achieve the effect of improving protection, low maintenance cost, and avoiding deformation or depression.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0023] As an embodiment of the present invention, the displacement device 9 includes four servo electric cylinders, hinges are installed at both ends of the servo electric cylinders, and the hinge on one side is installed on the protective frame 8. The servo electric cylinder is respectively installed on the four frames of the protective frame 8 through hinges, and the hinge on the other side is installed on the side wall of the laser cutting machine body 10 or the No. 2 electromagnet 11. The cooperative work of the cylinders can make the laser cutting machine body 10 and the No. 2 electromagnet 11 reach any cutting position of the steel plate.

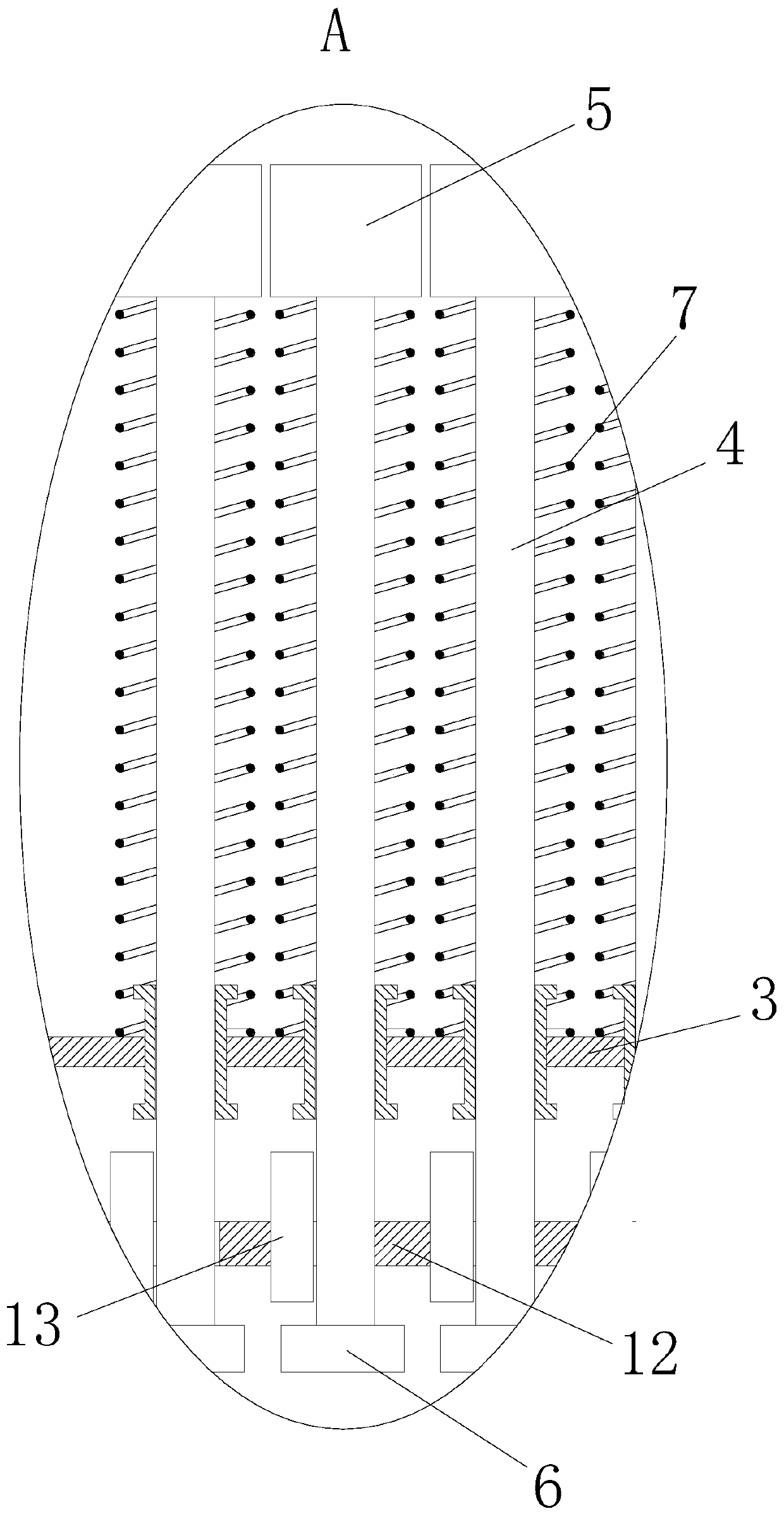

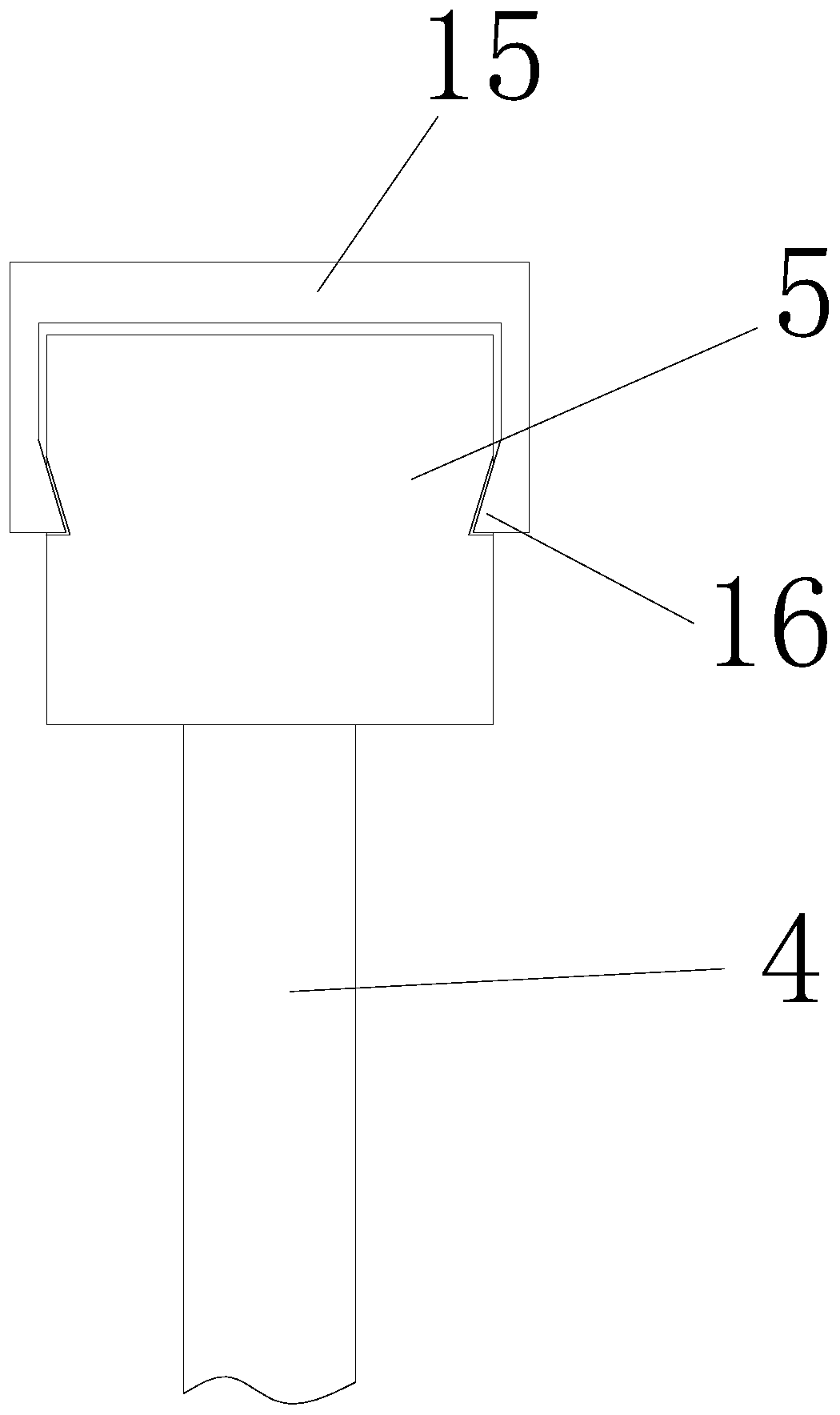

[0024] As an embodiment of the present invention, an auxiliary plate 12 is fixedly installed between the four columns 2, the auxiliary plate 12 is located below the mounting plate 3, and several mounting holes are provided on the auxiliary plate 12. No. three electromagnets 13 are fixedly installed on the side wall of the mounting hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com