Magnetic powder composite material and preparation method thereof

A composite material and powder technology, which is applied in the field of magnetic powder composite material and its preparation, can solve the problems of magnetic metal composite material pollution, insulation coating, etc., and achieve the effect of reducing atomization cost and saving procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the above objects, features and characteristics of the present invention more clearly understood, the relevant embodiments of the present invention are described in detail as follows with reference to the following drawings.

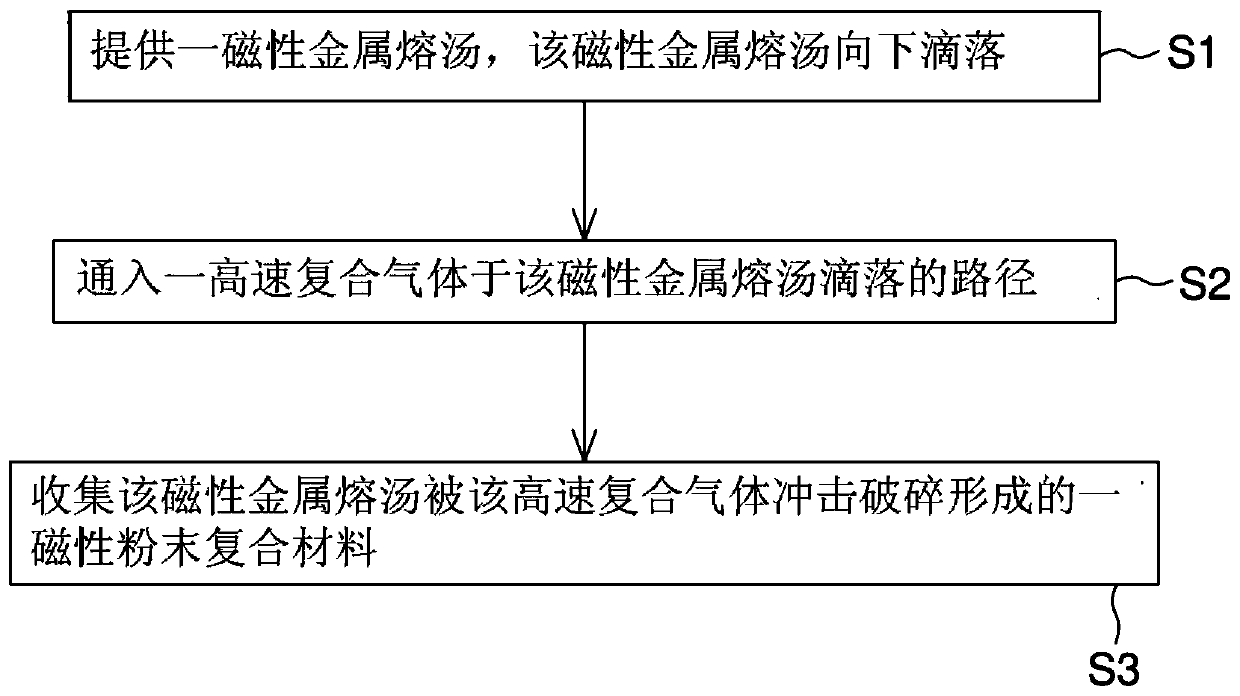

[0036] see figure 1 , figure 1 It is a flowchart of a method for preparing a magnetic metal composite material according to an embodiment of the present invention, and the steps include:

[0037] Step S1: providing a magnetic metal molten soup, and the magnetic metal molten soup drips downward;

[0038] Step S2: introducing a high-speed composite gas into the path where the magnetic metal molten soup drips; and

[0039] Step S3 : collecting a magnetic powder composite material formed by impacting and crushing the magnetic metal molten soup by the high-speed composite gas.

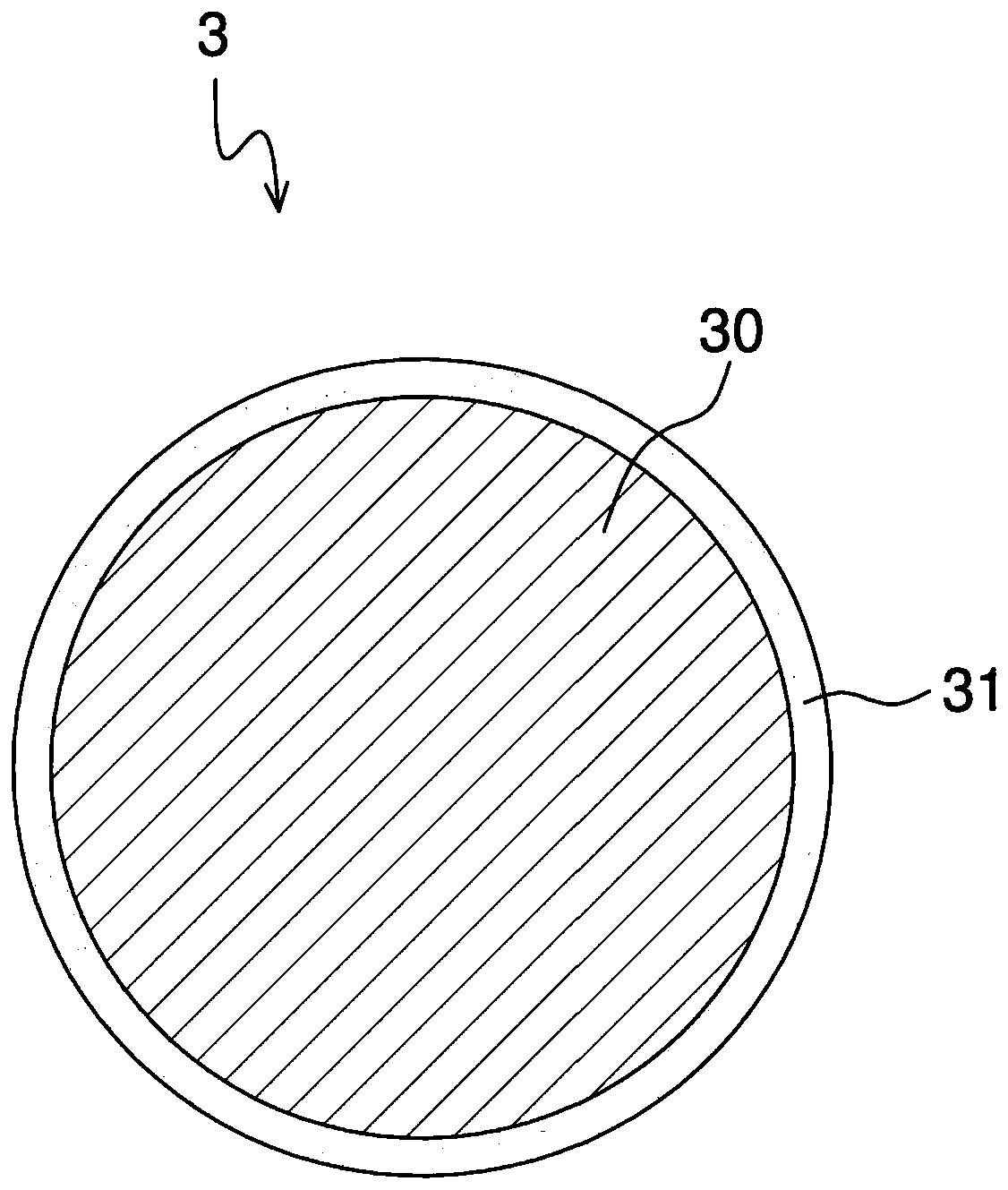

[0040] see figure 2 , figure 2 It is a schematic diagram of the preparation equipment of the magnetic metal composite material according to the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com