Wound dressing with antibacterial and bacterial warning functions and preparation method thereof

A wound dressing and functional technology, applied in dressings, non-adhesive dressings, bandages, etc., can solve the problems of complex preparation process and high production cost, and achieve the effect of simple process steps, strong peeling effect, and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

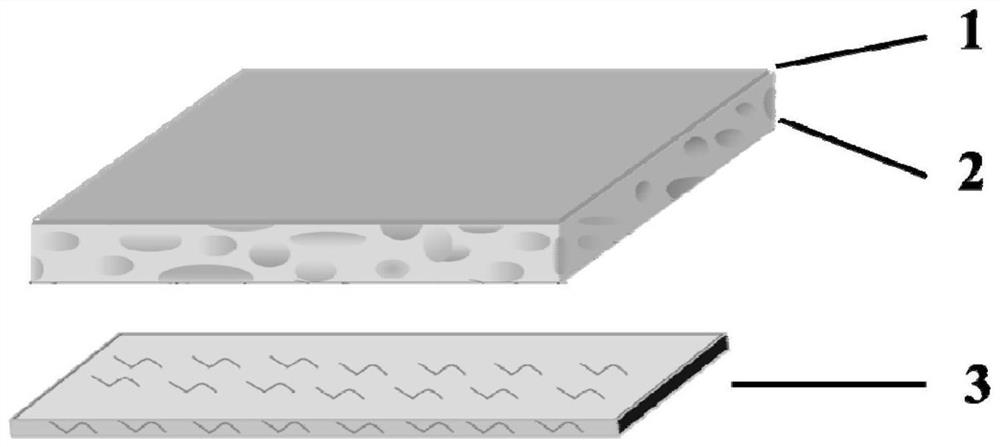

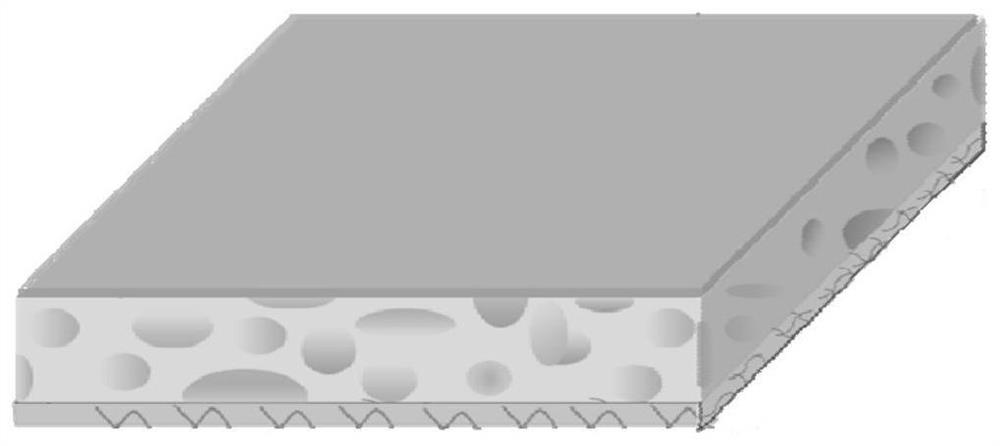

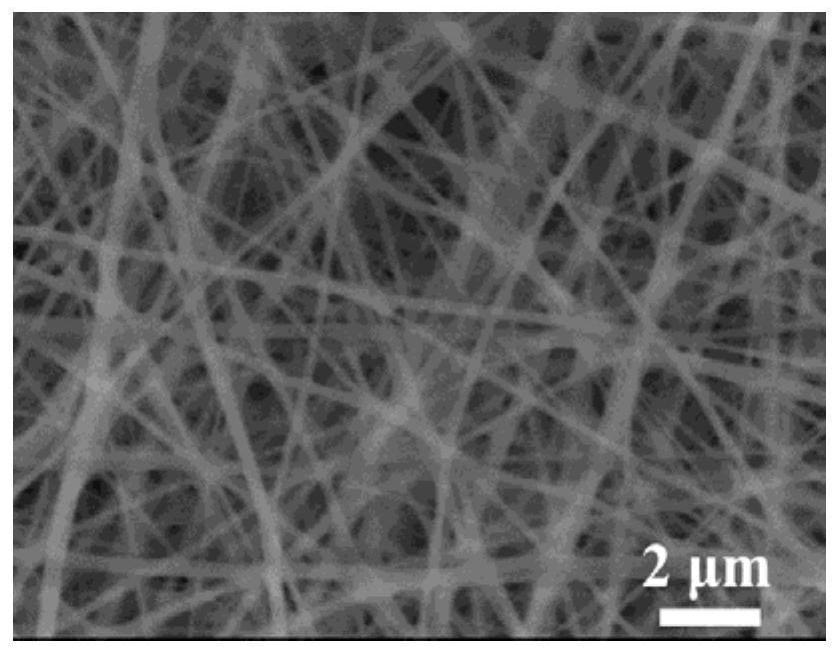

[0032] The steps of the present embodiment are as follows:

[0033] (1) Prepare polyvinyl alcohol foam with dense top surface and porous structure in the lower part

[0034] The polyvinyl alcohol was dissolved in 90 ° C deionized water, and then cooled to room temperature, and then added formaldehyde and concentrated sulfuric acid and mixed to form a reaction liquid, and then the reaction liquid was heated in an oven to 80 ° C for 2h, to obtain a dense top surface, the lower part is a porous structure of the polyvinyl alcohol foam, the reaction liquid, the concentration of polyvinyl alcohol is 80g / L, the ratio of the mass of polyvinyl alcohol to the volume of formaldehyde is 1:0.6, the ratio of the mass of polyvinyl alcohol to the volume of concentrated sulfuric acid is 1:0. 13, the mass unit of polyvinyl alcohol is g, and the volume unit of formaldehyde and concentrated sulfuric acid is mL;

[0035] (2) Soak and dry

[0036] The polyvinyl alcohol foam obtained in step (1) was r...

Embodiment 2

[0046] The steps of the present embodiment are as follows:

[0047] (1) Prepare polyvinyl alcohol foam with dense top surface and porous structure in the lower part

[0048] The polyvinyl alcohol was dissolved in 100 ° C deionized water, and then cooled to room temperature, and then added butyral and concentrated sulfuric acid and mixed to form a reaction liquid, and then the reaction liquid was heated in an oven to 90 ° C insulation for 1h, to obtain a dense top surface, the lower part is a porous structure of the polyvinyl alcohol foam, the reaction liquid, the concentration of polyvinyl alcohol is 100g / L, the ratio of the mass of polyvinyl alcohol to the volume of butyral is 1:0.5, the ratio of the mass of polyvinyl alcohol to the volume of concentrated sulfuric acid is 1:0. 05, the mass unit of polyvinyl alcohol is g, and the volume unit of butyral and concentrated sulfuric acid is mL;

[0049] (2) Soak and dry

[0050]The polyvinyl alcohol foam obtained in step (1) was rep...

Embodiment 3

[0056] The steps of the present embodiment are as follows:

[0057] (1) Prepare polyvinyl alcohol foam with dense top surface and porous structure in the lower part

[0058] The polyvinyl alcohol was dissolved in 120 ° C deionized water, and then cooled to room temperature, and then added butyral and concentrated sulfuric acid and mixed to form a reaction liquid, and then the reaction liquid was heated in an oven to 80 ° C for 2h, to obtain a dense top surface, the lower part is a porous structure of the polyvinyl alcohol foam, the reaction solution, the concentration of polyvinyl alcohol is 50g / L, the mass of polyvinyl alcohol and the volume ratio of butyral is 1:1, the ratio of the mass of polyvinyl alcohol to the volume of concentrated sulfuric acid is 1:0. 04, the mass unit of polyvinyl alcohol is g, and the volume unit of butyral and concentrated sulfuric acid is mL;

[0059] (2) Soak and dry

[0060] The polyvinyl alcohol foam obtained in step (1) was repeatedly cleaned wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com