A kind of preparation method of quick rehydration yuba

A kind of yuba, fast technology, applied in the field of preparation of rapid rehydration yuba, can solve the problems of nutrient loss, poor convenience, soaking for a long time, etc., and achieve the effects of rich nutrients, fast heating speed and fluffy product organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

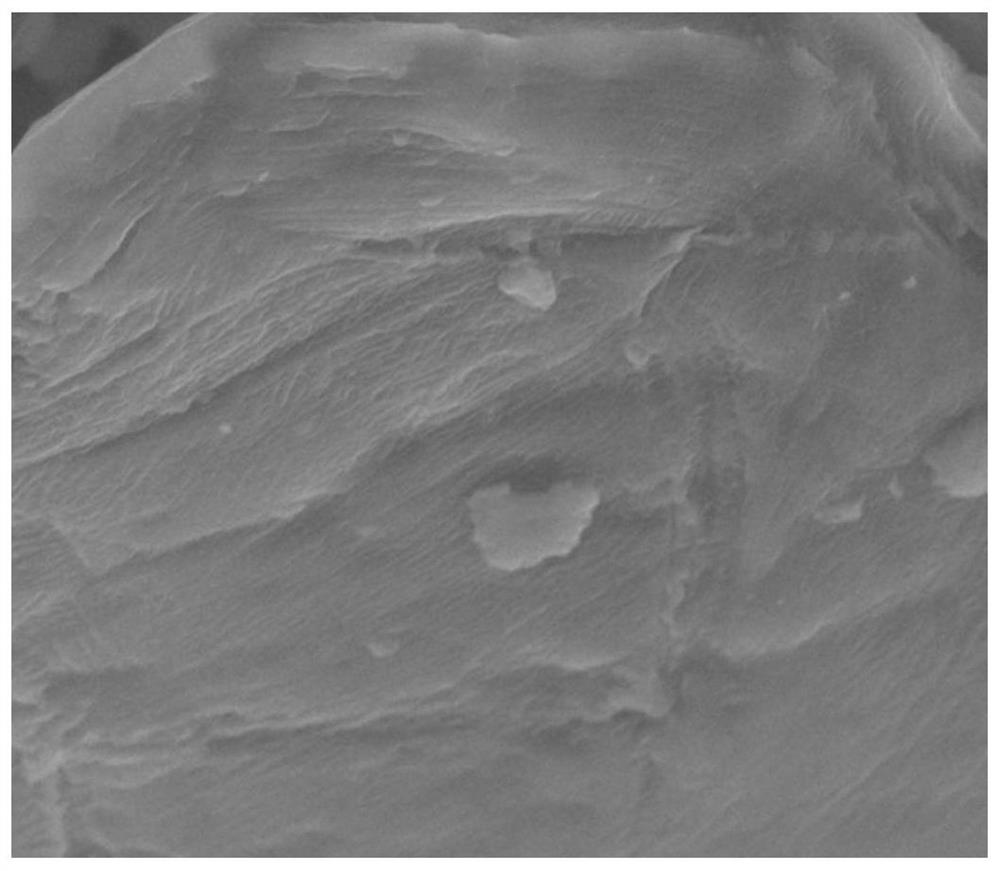

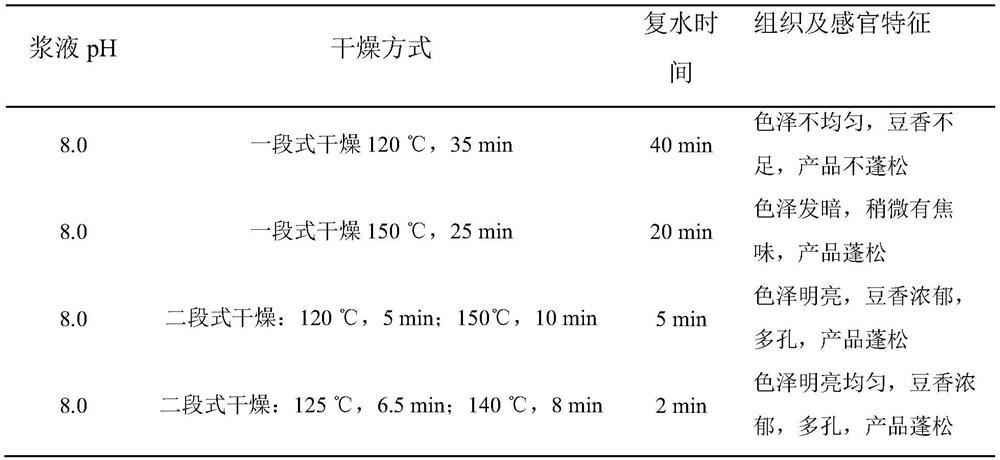

[0026] Select soybeans with plump particles and no mildew, soak the soybeans in purified water (weight ratio of soybeans and purified water is 1:5) at 25°C for 12 hours, grind and filter, keep the raw soybean milk in a boiling state for 3-5 minutes after boiling, filter to remove impurities, To obtain cooked soy milk; add edible sodium bicarbonate to the cooked soy milk, adjust the pH of the cooked soy milk to 7.5; put the cooked soy milk in a bean curd pot and heat it to 85°C to cook the pulp at a constant temperature, and the surface of the cooked milk in the bean curd pot forms a lump for 5 to 8 minutes. Layer oily film, pick the film to obtain wet yuba after forming, and then pass through 2-stage tunnel far-infrared drying: the drying temperature of the first stage is 120 °C for 5 minutes, the second temperature is 130 °C for 6 minutes, and the moisture content of the product is 14%. The prepared yuba product can be cooked and eaten after being rehydrated at room temperatu...

Embodiment 2

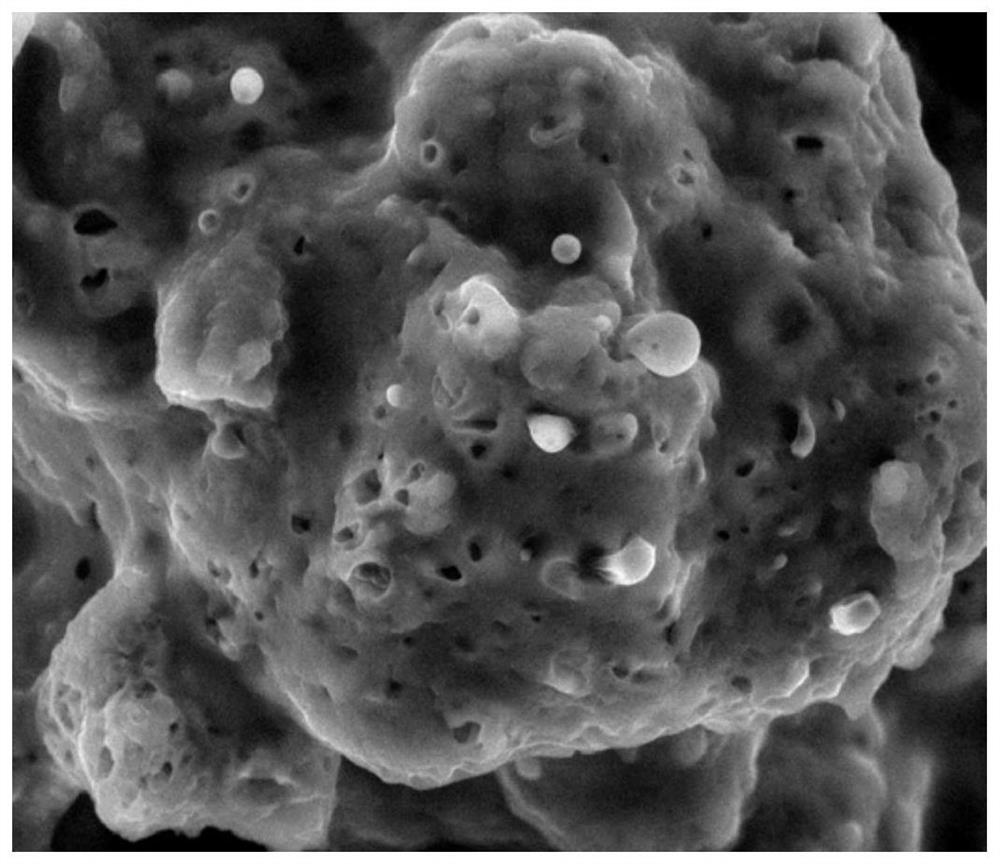

[0028] Select soybeans with plump particles and no mildew, soak the soybeans in purified water (weight ratio of soybeans and purified water is 1:5) at 25°C for 12 hours, grind and filter, keep the raw soybean milk in a boiling state for 3-5 minutes after boiling, filter to remove impurities, To obtain cooked soy milk; add edible sodium bicarbonate to the cooked soy milk, adjust the pH of the cooked soy milk to 8; put the cooked soy milk into a bean curd pot and heat it to 85°C to cook the pulp at a constant temperature, and the surface of the cooked pulp in the yuba pot forms a lump for 5 to 8 minutes. Layer oily film, pick the film to obtain wet yuba after forming, and then pass through 2-stage tunnel far-infrared drying: the drying temperature of the first stage is 125 °C for 6.5 minutes, the second temperature is 140 °C for 8 minutes, and the product contains water. rate 12%. The prepared yuba product can be cooked and eaten after being rehydrated at room temperature for 2 ...

Embodiment 3

[0030] Select soybeans with plump particles and no mildew, soak the soybeans in purified water (weight ratio of soybeans and purified water is 1:5) at 25°C for 12 hours, grind and filter, keep the raw soybean milk in a boiling state for 3-5 minutes after boiling, filter to remove impurities, To obtain cooked pulp; add edible sodium bicarbonate to the cooked soy milk, adjust the pH of the cooked soy milk to 8.5; put the cooked soy milk in a bean curd pot and heat it to 85°C to cook the pulp at a constant temperature, and the cooked pulp in the yuba pot will form a lump on the surface for 5 to 8 minutes. Layer oily film, pick the film to obtain wet yuba after forming, and then pass through 2-stage tunnel far-infrared drying: the drying temperature of the first stage is 130 °C for 8 minutes, the second temperature is 150 °C for 10 minutes, and the moisture content of the product is 10%. The prepared yuba product can be cooked and eaten after being rehydrated at room temperature f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com