Hole plugging welding gun for upper end plug of nuclear fuel rod

A technology for nuclear fuel rods and plugging holes, which is applied in the field of welding torches and can solve problems such as affecting welding containers, product quality, and continuous maintenance of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

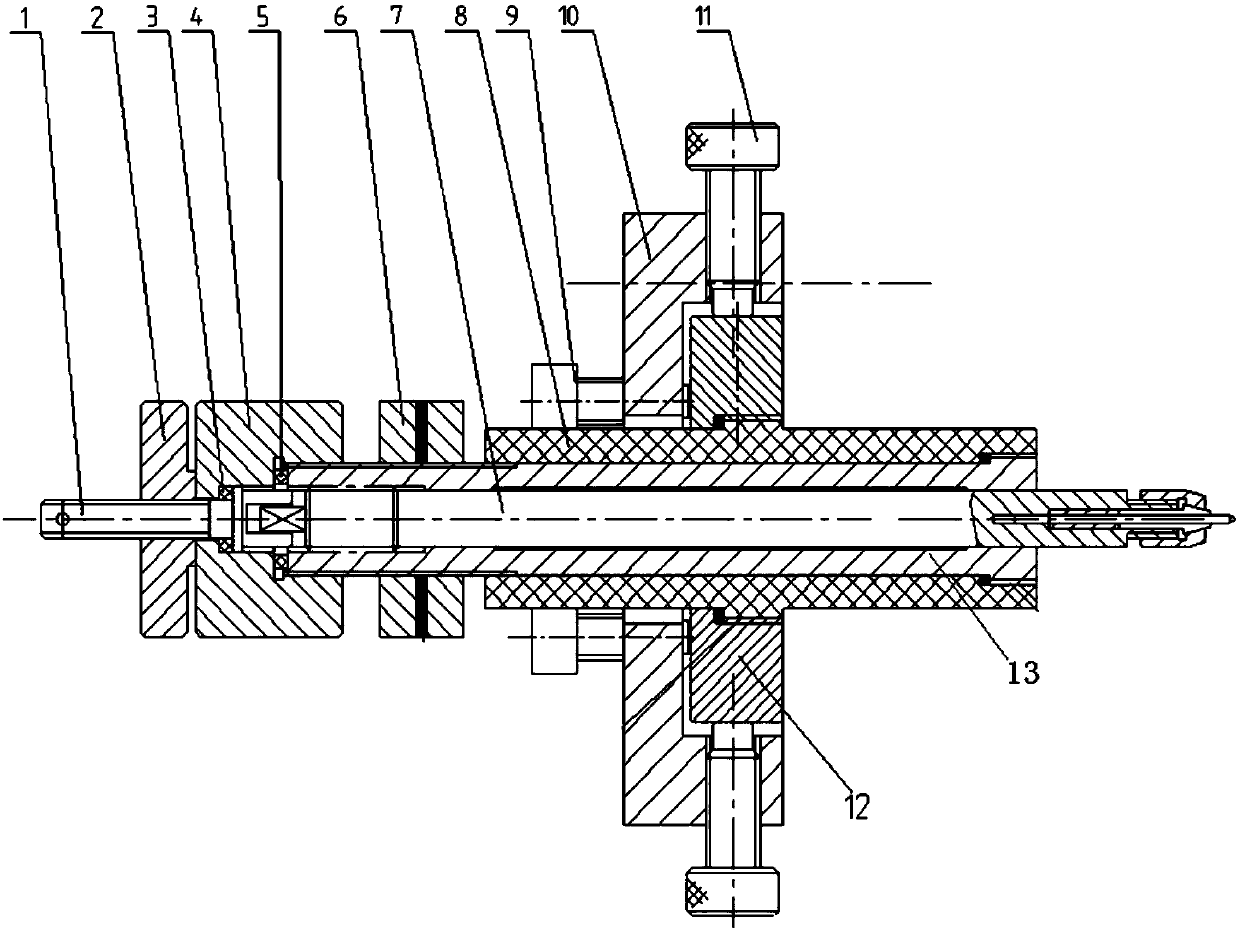

[0023] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

[0024] The insulating bakelite cover 8 is a cylindrical structure, and its inside is tightly installed with a tungsten pole positioning seat 13 by screwing, and the left end of the tungsten pole positioning seat 13 (such as figure 1 Shown) stretches out insulating Bakelite cover 8, and is processed with screw thread on the part outer wall that stretches out. The right end of the tungsten pole positioning seat 13 is located inside the insulating bakelite sleeve 8, and a section of the right end of the tungsten pole positioning seat 13 is processed with a boss structure, and the boss is in sealing contact with the insulating bakelite sleeve 8.

[0025] The inside of the tungsten pole positioning seat 13 is threadedly installed with the tungsten pole 7 , and the left end of the tungsten pole 7 is installed with the adjusting screw 1 , and the right end pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com