Microscopic imaging system

A microscopic imaging and image processing technology, applied in the field of optical imaging, can solve the problems of unevenness, clear imaging, and the problem of focusing is not well solved, and achieves the effect of reducing the requirement of consistency and improving the production efficiency of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

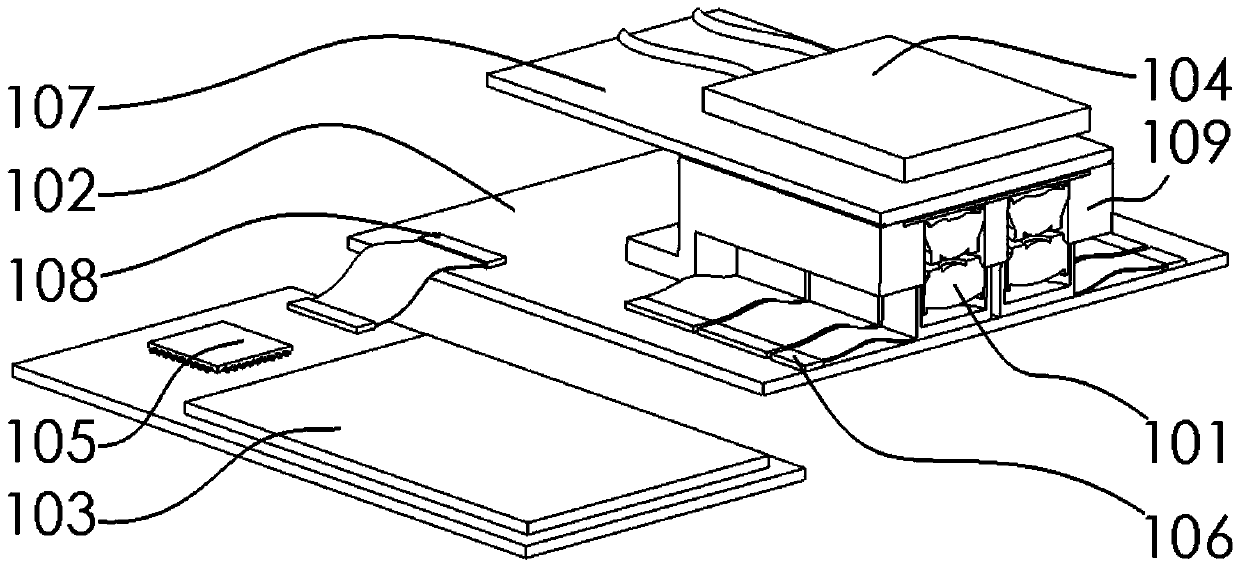

[0071] Such as figure 1 As shown, in this embodiment, the microscopic imaging system includes six unit microscopic imaging modules 101, the six unit microscopic imaging modules 101 are arranged in an array structure with the minimum physical distance, and are fixed by a fixing mechanism 109 On the data acquisition card 102. The six unit microscopic imaging modules 101 are respectively connected to the data acquisition card 102 through the board cable interface 106 . Above the unit microscopic imaging module 101, a carrying platform ( figure 1 not shown), the sample 107 to be tested can be set on the carrying platform. At the same time, an illumination source 104 is provided above the carrying platform. The data acquisition card 102 is provided with six independent image processing chips ( figure 1 not shown) independently control the photosensitive modules and focus motors 1013 in the six unit microscopic imaging modules 101 ( figure 1 not shown). The image processing ch...

Embodiment 2

[0076] Such as Figure 5 As shown, on the basis of Embodiment 1, the illumination light source provided above the carrying platform is a fluorescence excitation light source, and the fluorescence excitation light source can use an oblique incident laser 1041 . It can use a 488nm wavelength laser. When a fluorescence excitation light source is used, a corresponding fluorescence excitation filter 302 is added to each unit microscopic imaging module 101 .

Embodiment 3

[0078] Such as Image 6 As shown, on the basis of Embodiment 1, the illumination light source provided above the carrying platform is a fluorescent light source, and the fluorescent excitation light source can use an LED light emitting chip 1042 . It can use LED light-emitting chips with a wavelength of 488nm. When a fluorescence excitation light source is used, a corresponding fluorescence excitation filter 302 is added to each unit microscopic imaging module 101 .

[0079] Figure 7 to Figure 9 for Figure 5 with Image 6 Different embodiments of the unit microscopic imaging module 101 in the illustrated embodiment.

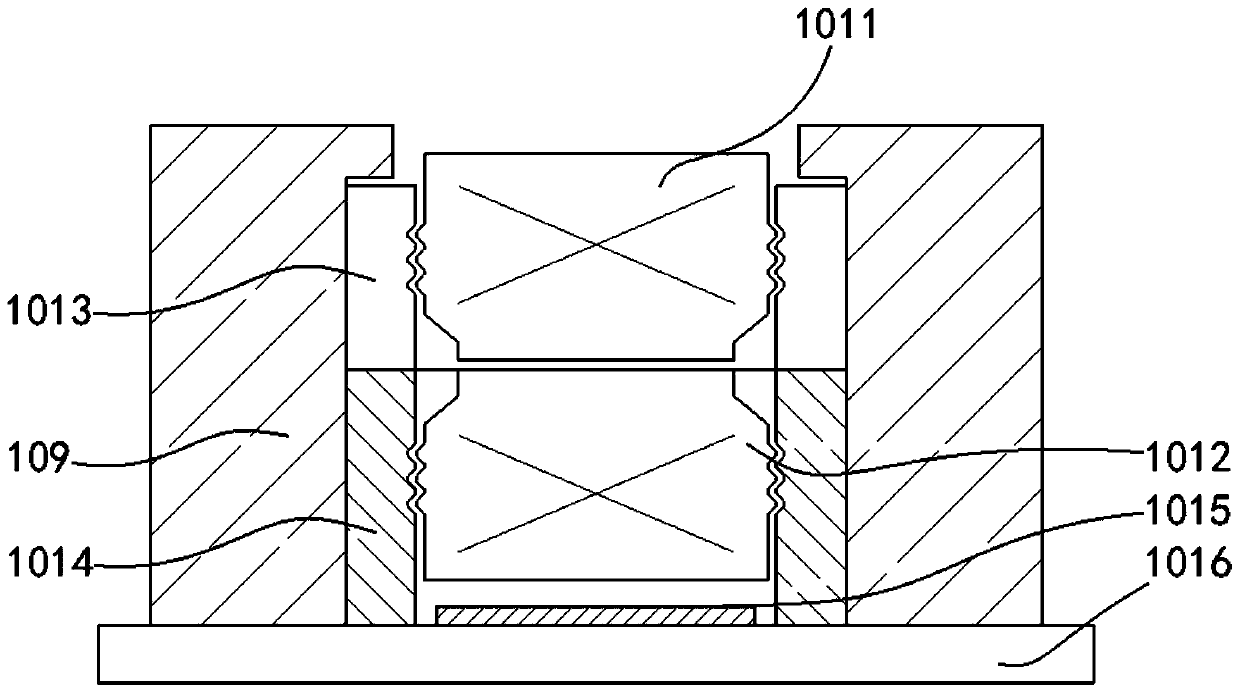

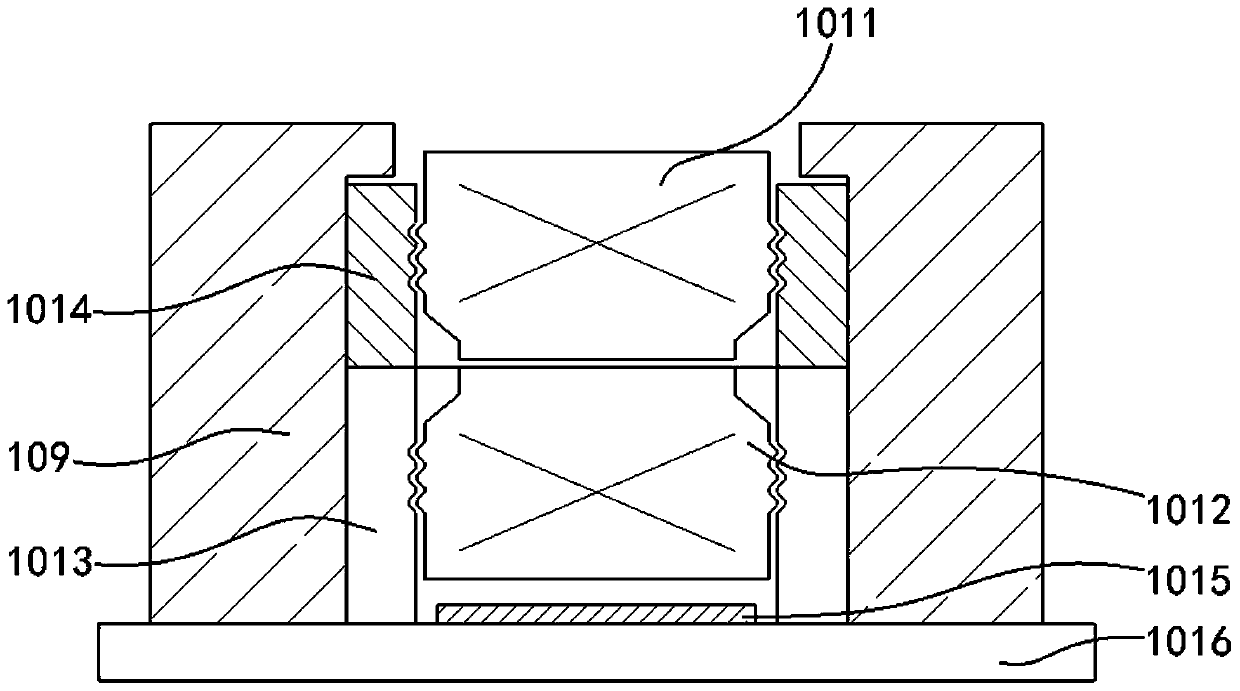

[0080] Such as Figure 7 As shown, in this embodiment, the fluorescence excitation filter 302 is located between the first lens group 1011 and the sample 107 in the unit microscope imaging module 101 . Such as Figure 8 As shown, in this embodiment, the fluorescence excitation filter 302 is located between the first lens group 1011 and the second lens gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com