Split plug-in type functional conversion interface

A conversion interface and plug-in technology, which is applied in the field of split plug-in functional conversion interface, can solve the problems of the circuit board pads falling off, the circuit board size being large, and the circuit board being scrapped, etc., so as to improve the production efficiency of finished products, The effect of improving processing efficiency and reducing the possibility of damage by welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

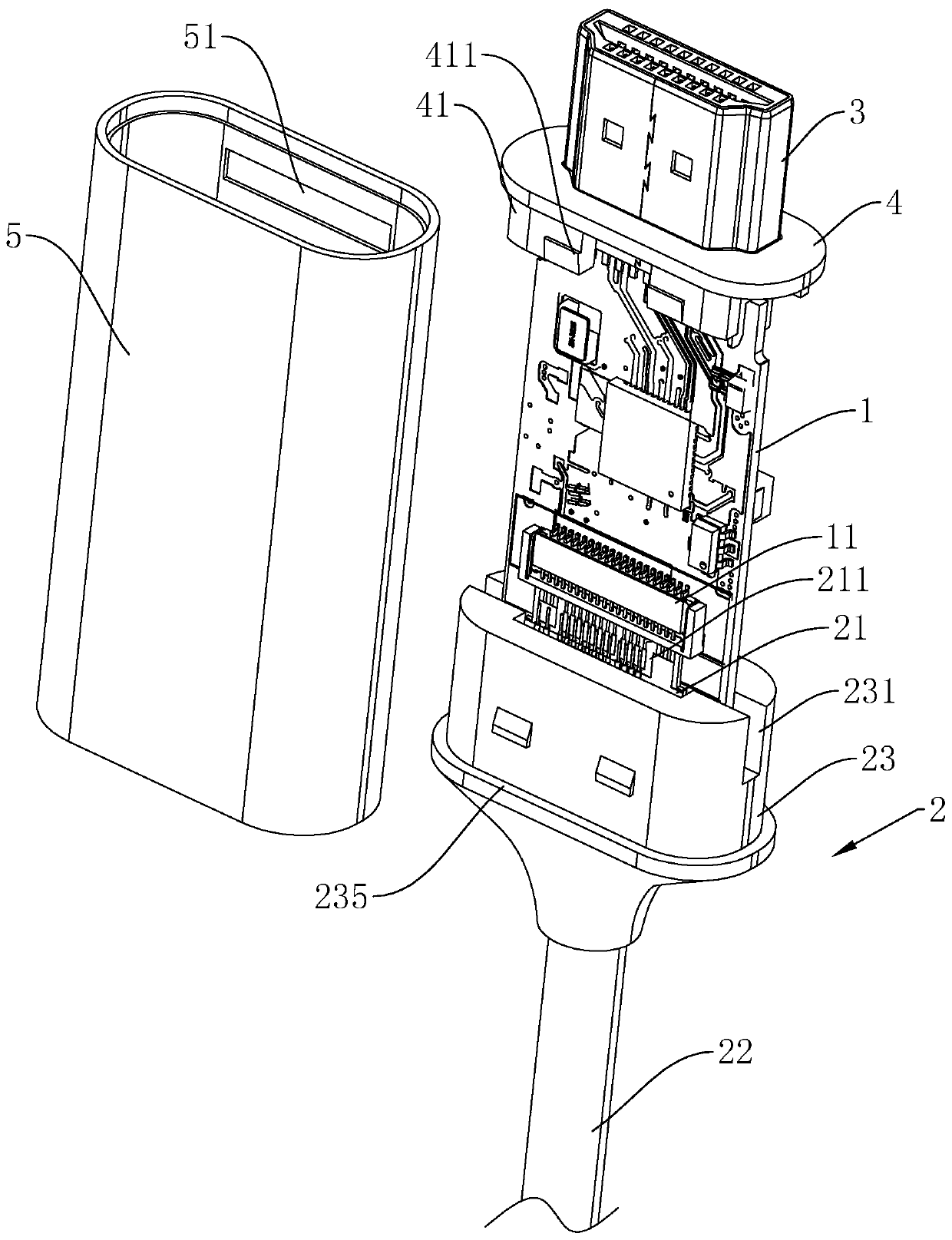

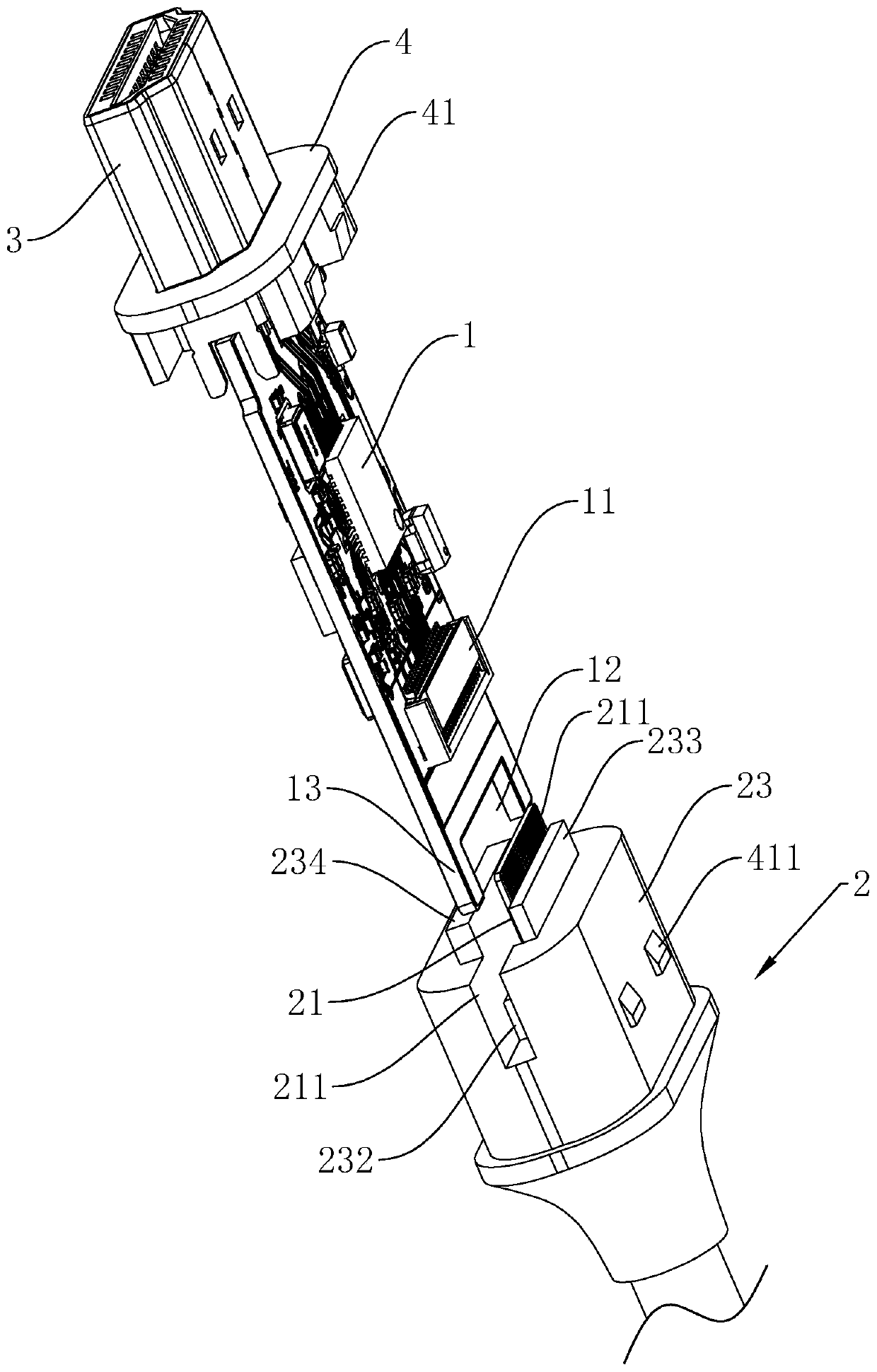

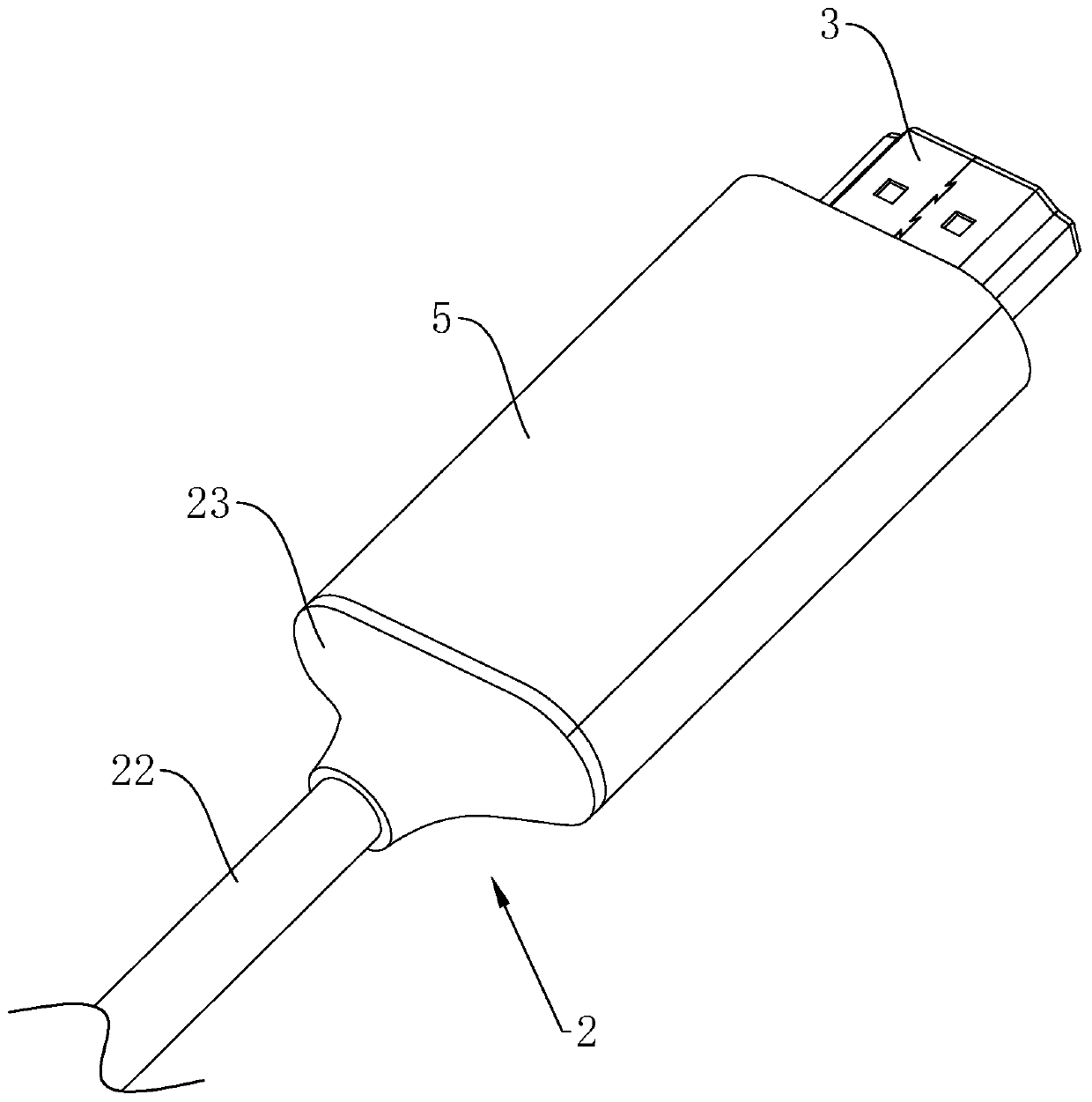

[0037] Example: such as figure 1 As shown, it is a split plug-in functional conversion interface disclosed by the present invention, including an upper-level access terminal 2, a circuit main board 1 and a lower-level connection terminal 3 arranged in sequence, and the connection between the upper-level access terminal 2 and the circuit main board 1 The line input terminal is detachably connected, and the lower-level connection terminal 3 is connected to the output terminal of the circuit board 1 .

[0038] Such as figure 1 and 2 As shown, the upper-level access terminal 2 includes a connection base 23 , a circuit connection board 21 and a coaxial cable 22 . The end face of the connecting seat 23 facing the circuit board 1 is integrally formed with a first reinforcing plate 233 and a second reinforcing plate 234 arranged in parallel. 211 ; the coaxial lines 22 are divided into 8 pieces, and one end of the 8 coaxial lines 22 penetrates into the connection seat 23 and exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com