Medical non-woven fabric with high permeability

A breathable, non-woven fabric technology, applied in textiles and papermaking, improved handle fiber, biochemical fiber treatment, etc., can solve the problems of non-permanence, slow falling, etc., achieve high bonding fastness, reduce absorption Liquid volume, the effect of increasing the breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

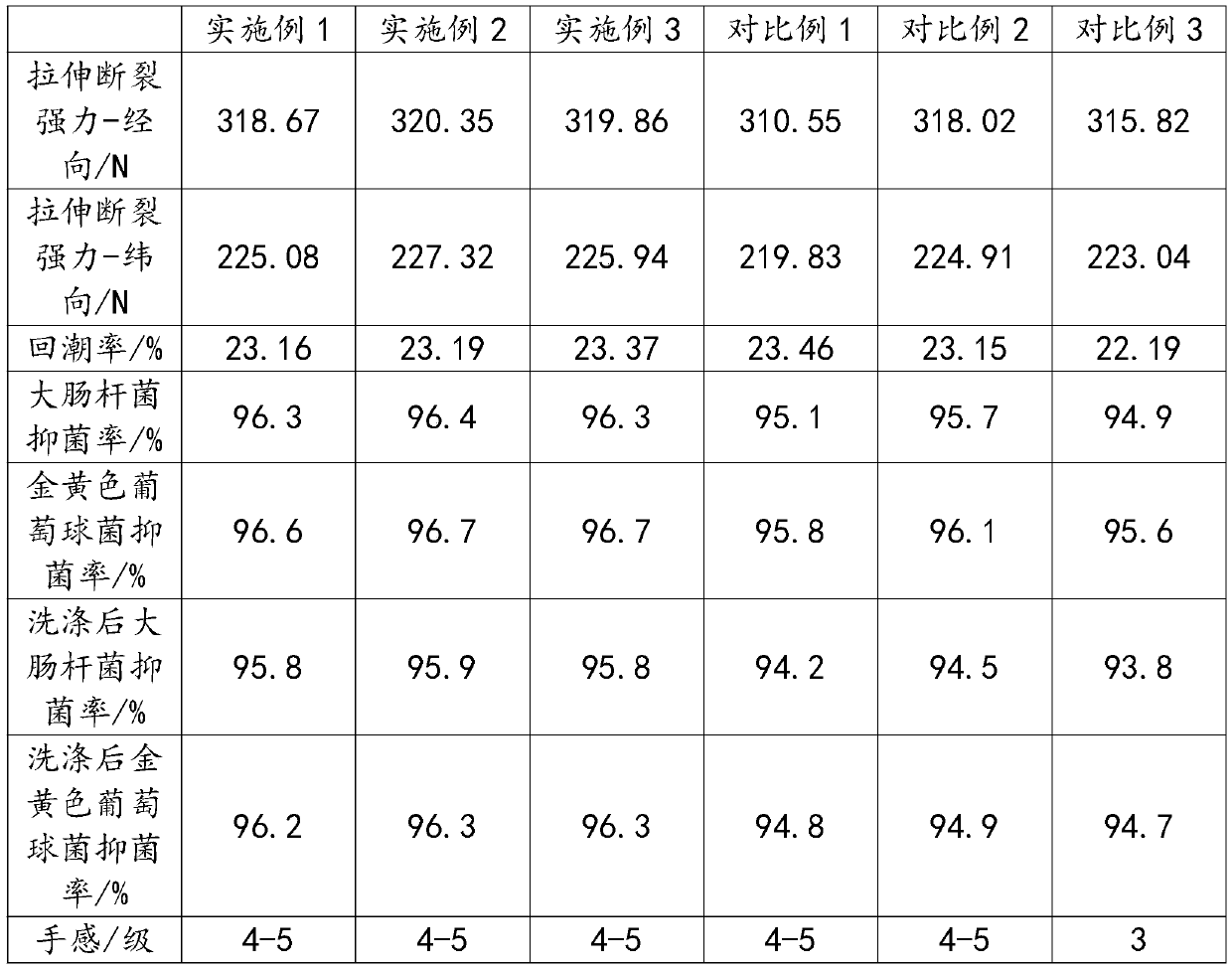

Examples

Embodiment 1

[0041] A kind of highly air-permeable medical non-woven fabric, is made base cloth by modified seaweed fiber and viscose fiber, and base cloth is made through finishing liquid again; Wherein, the mass ratio of modified seaweed fiber and viscose fiber is 1: 2;

[0042] The highly air-permeable non-woven fabric is prepared by the following method:

[0043] The first step is to mix the modified seaweed fiber and viscose fiber according to the mass ratio, then open, remove impurities, and form a web on the blowing-carding equipment. m 2 The non-woven fabric obtains the base cloth;

[0044] The second step is to raise the temperature of the finishing solution to 40°C, put the wet base cloth into the finishing solution according to the bath ratio of 1:20, keep it warm for 55 minutes, and add sodium carbonate so that the mass concentration of sodium carbonate in the solution is 15g L -1 , heated up to 95° C., kept warm for 28 minutes, washed with water after cooling down, and drie...

Embodiment 2

[0046] A kind of highly air-permeable medical non-woven fabric, is made base cloth by modified seaweed fiber and viscose fiber, and base cloth is made through finishing liquid again; Wherein, the mass ratio of modified seaweed fiber and viscose fiber is 1: 2-3;

[0047] The highly air-permeable non-woven fabric is prepared by the following method:

[0048] The first step is to mix the modified seaweed fiber and viscose fiber according to the mass ratio, then open, remove impurities, and form a web on the blowing-carding equipment. m 2 The non-woven fabric obtains the base cloth;

[0049] The second step is to raise the temperature of the finishing solution to 43°C, put the wet base cloth into the finishing solution according to the bath ratio of 1:20, keep it warm for 60 minutes, and add sodium carbonate so that the mass concentration of sodium carbonate in the solution is 15g L -1 , heated up to 96°C, kept warm for 29 minutes, washed with water after cooling down, and drie...

Embodiment 3

[0051] A kind of highly air-permeable medical non-woven fabric, is made base cloth by modified seaweed fiber and viscose fiber, and base cloth is made through finishing liquid again; Wherein, the mass ratio of modified seaweed fiber and viscose fiber is 1: 3;

[0052] The highly air-permeable non-woven fabric is prepared by the following method:

[0053] The first step is to mix the modified seaweed fiber and viscose fiber according to the mass ratio, then open, remove impurities, and form a web on the blowing-carding equipment. m 2 The non-woven fabric obtains the base cloth;

[0054] The second step is to raise the temperature of the finishing solution to 45°C, put the wet base cloth into the finishing solution according to the bath ratio of 1:20, keep it warm for 65 minutes, and add sodium carbonate so that the mass concentration of sodium carbonate in the solution is 15g L -1 , heated up to 98° C., kept warm for 30 minutes, washed with water after cooling down, and drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com