Auto-reverse tape deck comprising switching device

A technology of conversion device and tape transport mechanism, which is applied in the direction of speed change/reversal device, record carrier drive mechanism, manual/electromagnetic control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

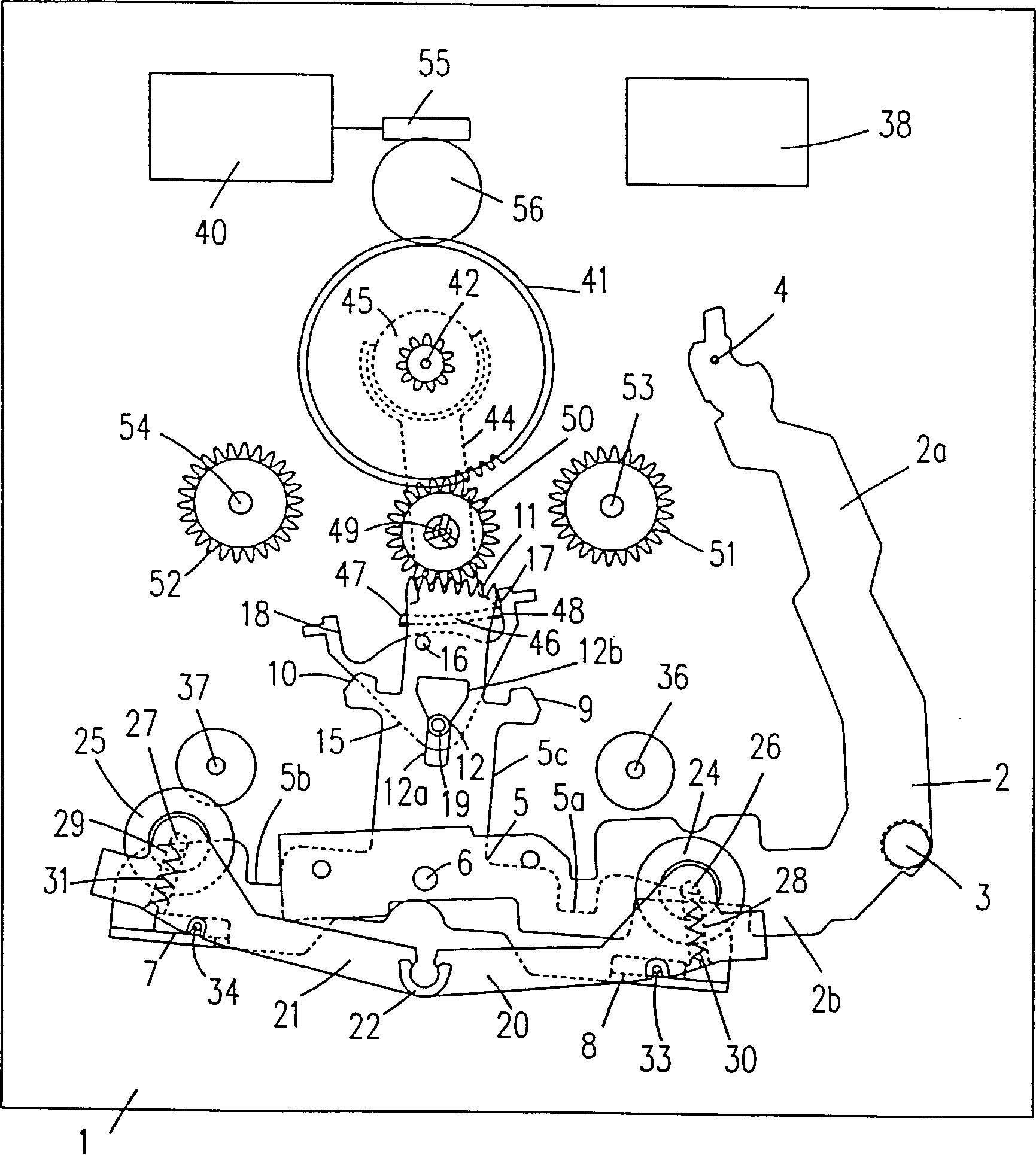

[0039] figure 1 , 2, 3, 4 and 5 diagrammatically represent the components of the automatic rewind mechanism in plan view in different operating states. figure 1 Indicates the operating position of the first tape transport direction (fast reverse playback), such as figure 1 As shown, the belt transport mechanism of the present invention includes a bottom plate made of a deck 1, on which a bearing part 2 is fixed so as to rotate around a pivot 3, the bearing part 2 has an arm 2a and an arm 2b, and the arm 2a of the bearing part 2 With guide pin 4. The guide pin 2c engages with an unillustrated cam surface of an unillustrated cam disc. A cam disc, not shown, applies to the guide pin 2c the force required to turn the carrier part 2 about the pivot 3 . A head tape guide member not shown is supported on the carrier member 2 . A tape guide member, not shown, moves towards the tape in the cassette by rotating the carrying member 2 about the pivot 3, not shown. The drive rod 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com