Photocatalytic long-acting stain-resistant elastic acrylate emulsion and preparation method thereof

A technology of acrylate and alkyl acrylate, which is applied in the field of elastic acrylate emulsion and its preparation, can solve the problems of reduced coating film decoration effect, coating film pollution, easy dusting, etc., to reduce adhesion and suction, and reduce static electricity Adsorption, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

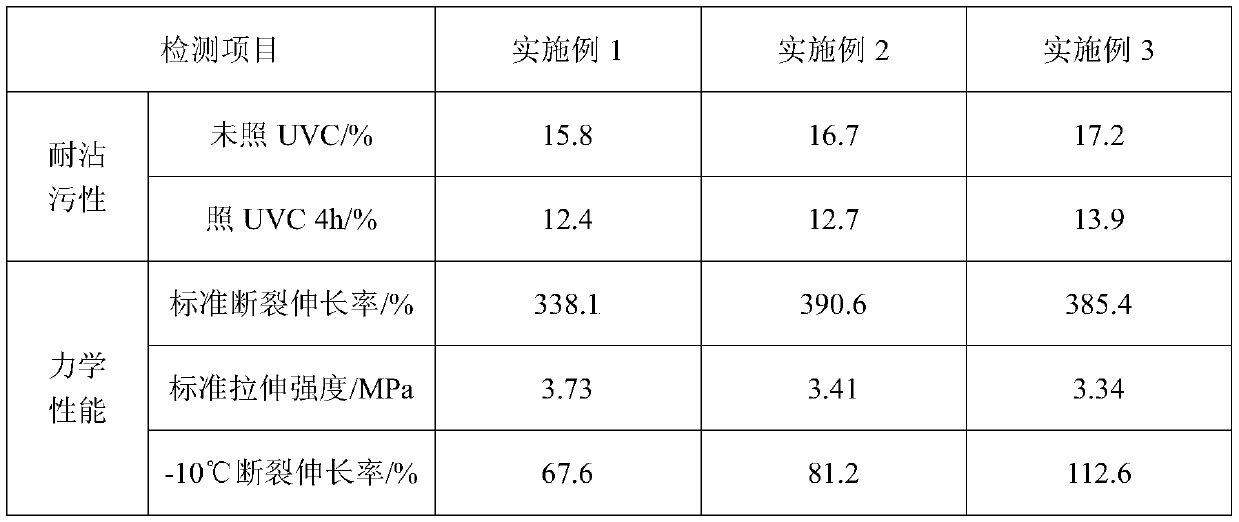

Embodiment 1

[0021] A preparation method of a photocatalyzed long-lasting stain-resistant elastic acrylate emulsion, comprising the following steps (the following raw materials are calculated in parts by weight):

[0022] a) Preparation of base liquid: Add 17.3 parts of deionized water, (propenyloxy)methyl nonylphenol polyoxyethylene ether sulfonic acid into a polymerization kettle equipped with a stirrer, condenser, and constant-flow pump feeding device 0.03 part of ammonium salt, the temperature in the kettle is raised to 80°C;

[0023] b) Preparation of pre-emulsion: Add 29.8 parts of deionized water, (propenyloxy) methyl nonylphenol polyoxyethylene ether into the pre-emulsification tank with monomer metering tank and agitator under normal temperature and pressure 0.05 parts of ammonium sulfonate, 0.39 parts of potassium lauryl phosphate, 0.1 parts of nonylphenol polyoxyethylene ether, 8.03 parts of methyl methacrylate, 39.75 parts of n-butyl acrylate, 2.06 parts of acrylonitrile, 0.26 ...

Embodiment 2

[0027] A method for preparing a photocatalytic long-lasting stain-resistant elastic acrylate emulsion, comprising the following steps (the following raw materials are calculated in parts by weight):

[0028] a) Preparation of base liquid: Add 17.3 parts of deionized water, (propenyloxy)methyl nonylphenol polyoxyethylene ether sulfonic acid into a polymerization kettle equipped with a stirrer, condenser, and constant-flow pump feeding device 0.03 part of ammonium salt, the temperature in the kettle is raised to 80°C;

[0029] b) Preparation of pre-emulsion: Add 29.8 parts of deionized water, (propenyloxy) methyl nonylphenol polyoxyethylene ether into the pre-emulsification tank with monomer metering tank and agitator under normal temperature and pressure 0.05 parts of ammonium sulfonate, 0.39 parts of potassium lauryl phosphate, 0.1 parts of nonylphenol polyoxyethylene ether, 8.72 parts of methyl methacrylate, 33.53 parts of n-butyl acrylate, 5.15 parts of 2-ethylhexyl acrylate...

Embodiment 3

[0033] A method for preparing a photocatalytic long-lasting stain-resistant elastic acrylate emulsion, comprising the following steps (the following raw materials are calculated in parts by weight):

[0034] a) Preparation of base liquid: Add 17.3 parts of deionized water, (propenyloxy)methyl nonylphenol polyoxyethylene ether sulfonic acid into a polymerization kettle equipped with a stirrer, condenser, and constant-flow pump feeding device 0.04 parts of ammonium salt, the temperature in the kettle is raised to 80°C;

[0035] b) Preparation of pre-emulsion: Add 29.8 parts of deionized water, (propenyloxy) methyl nonylphenol polyoxyethylene ether into the pre-emulsification tank with monomer metering tank and agitator under normal temperature and pressure 0.05 parts of ammonium sulfonate, 0.39 parts of potassium lauryl phosphate, 0.1 parts of nonylphenol polyoxyethylene ether, 8.27 parts of styrene, 39.43 parts of n-butyl acrylate, 1.54 parts of acrylonitrile, 0.59 parts of met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com