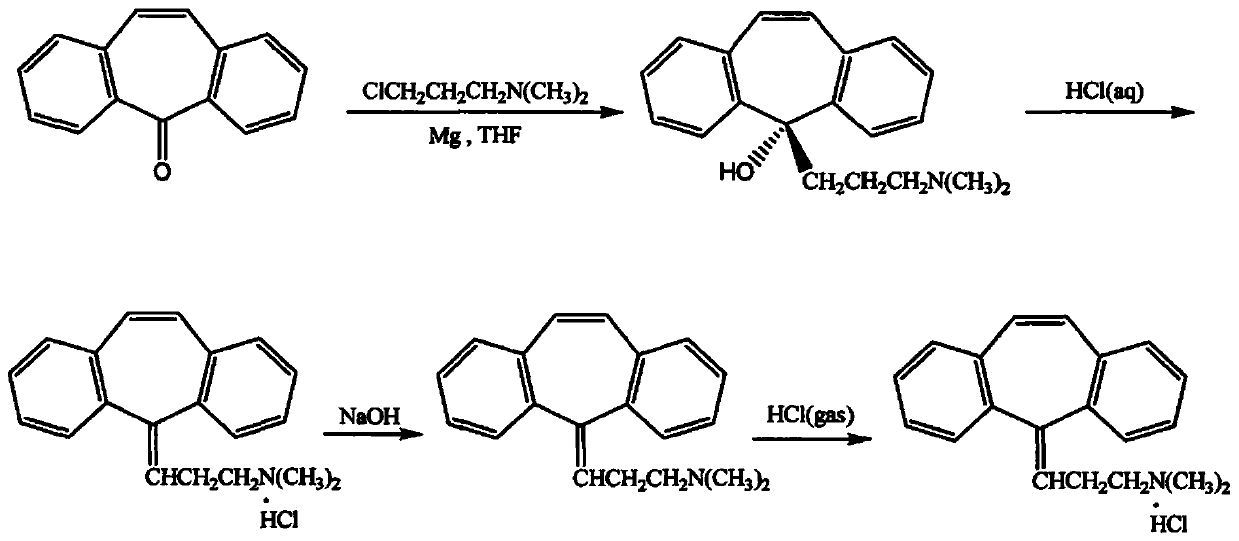

Refining method of cyclobenzaprine hydrochloride

A technology of cyclobenzaprine hydrochloride and refining method, which is applied in the field of medicine, can solve the problems of affecting the purification rate and difficulty in removal, and achieve the effects of high extraction rate, increased fluidity, and loose crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of refining method of cyclobenzaprine hydrochloride of this embodiment comprises the following preparation steps:

[0030] S1. First, in the extraction process of cyclobenzaprine hydrochloride in the later stage of processing, add dispersive adsorption powder to the mixed solution of cyclobenzaprine hydrochloride, and use a paddle stirrer to stir, and the axial and radial shunt effects are better. The crystals are uniform, the crystals are loose, and it is not easy to wrap impurities. Cyclobenzaprine hydrochloride is extracted by passing through dry hydrogen chloride gas, and the crude product of cyclobenzaprine hydrochloride is precipitated; the dispersed powder is specifically white carbon black powder, mordenite powder and Blends of hydrotalcite powders;

[0031] S2. Ethyl ether is added to the crude cyclobenzaprine hydrochloride for recrystallization, dissolved and stirred by steam pressurization, and kept at a constant temperature for later use;

[0032] S3...

Embodiment 2

[0037] A kind of refining method of cyclobenzaprine hydrochloride of this embodiment comprises the following preparation steps:

[0038] S1. First, in the extraction process of cyclobenzaprine hydrochloride in the later stage of processing, add dispersive adsorption powder to the mixed solution of cyclobenzaprine hydrochloride, and use a paddle stirrer to stir, and the axial and radial shunt effects are better. The crystals are uniform, the crystals are loose, and it is not easy to wrap impurities. Cyclobenzaprine hydrochloride is extracted by passing through dry hydrogen chloride gas, and the crude product of cyclobenzaprine hydrochloride is precipitated; the dispersed powder is specifically white carbon black powder, mordenite powder and Blends of hydrotalcite powders;

[0039] S2. Ethyl ether is added to the crude cyclobenzaprine hydrochloride for recrystallization, dissolved and stirred by steam pressurization, and kept at a constant temperature for later use;

[0040] S3...

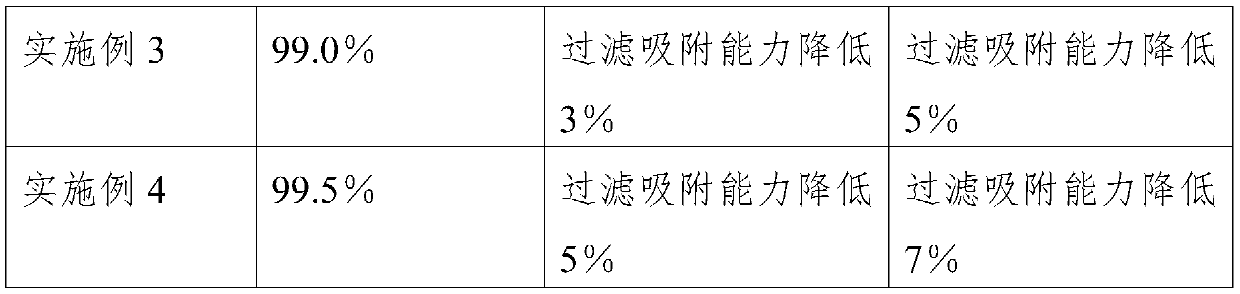

Embodiment 3

[0045] A kind of refining method of cyclobenzaprine hydrochloride of this embodiment comprises the following preparation steps:

[0046] S1. First, in the extraction process of cyclobenzaprine hydrochloride in the later stage of processing, add dispersive adsorption powder to the mixed solution of cyclobenzaprine hydrochloride, and use a paddle stirrer to stir, and the axial and radial shunt effects are better. The crystals are uniform, the crystals are loose, and it is not easy to wrap impurities. Cyclobenzaprine hydrochloride is extracted by passing through dry hydrogen chloride gas, and the crude product of cyclobenzaprine hydrochloride is precipitated; the dispersed powder is specifically white carbon black powder, mordenite powder and Blends of hydrotalcite powders;

[0047] S2. Ethyl ether is added to the crude cyclobenzaprine hydrochloride for recrystallization, dissolved and stirred by steam pressurization, and kept at a constant temperature for later use;

[0048] S3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com