Method for enhancing quality of soy sauce

A soy sauce flavor and substance technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, milk substitutes, etc., can solve the problems of unclear influence on substance metabolism, achieve increased anti-mold effect, strong bactericidal effect, and soft soy sauce salty effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Preparation of soy sauce using Tetradynococcus halophilus R44 and Zygomyces ruckeri ZQ02

[0032] (1) Koji making

[0033]Soak soybean meal with 1.2 times of water for 2 hours, sterilize at 121°C for 15 minutes, and cool to room temperature. Add 1.5‰ (V:V) Aspergillus oryzae spore powder according to the weight of raw materials (the total weight after soybean meal and wheat grains are mixed). , the mass ratio of wheat grains is 6:4) and fully mix well; cultivate in a biochemical incubator at 30°C, control the humidity at about 90% during the koji making process, turn the koji at the right time, make koji for 60 hours, and the surface of the koji material is covered with yellow The green mycelium is the song. Quality requirements for koji: well-developed hyphae, dense spores, no stickiness and burnt koji.

[0034] (2) fermentation

[0035] Mix the koji with 20% (W:V) brine at a volume ratio of 1:1.8. The mixed moromi was divided into 2L jars and fermented...

Embodiment 2

[0040] Embodiment 2: Determination of the quantity of Tetradneococcus halophilus R44 and Zygomyces rouckeri ZQ02

[0041] In order to confirm that the addition of strains can enhance the effect of Tetradynococcus halophilus R44 and Zygomyces rouckeri ZQ02 in the soy sauce fermentation process, the number of Tetradynococcus halophilus R44 and Zygosaccharomyces rouckeri ZQ02 was determined by plate counting method. Weigh 1g of moromi and pour it into a conical flask filled with sterilized glass beads and 99mL normal saline, mix evenly, and make gradient dilutions (respectively diluted to 10 -2 、10 -3 、10 -4 、10 -5 、10 -6 、10 -7 ), diluted and applied to MRS (containing 100mg·L -1 Natamycin, 100g·L - 1 NaCl) plate and Bengal red agar (sodium propionate 5g L -1 , 100g·L -1 NaCl) plate, cultured at 30°C for 4-6 days and counted.

[0042] The results showed that the addition of Tetradococcus halophilus could strengthen the bacteria in the fermentation process of soy sauce....

Embodiment 3

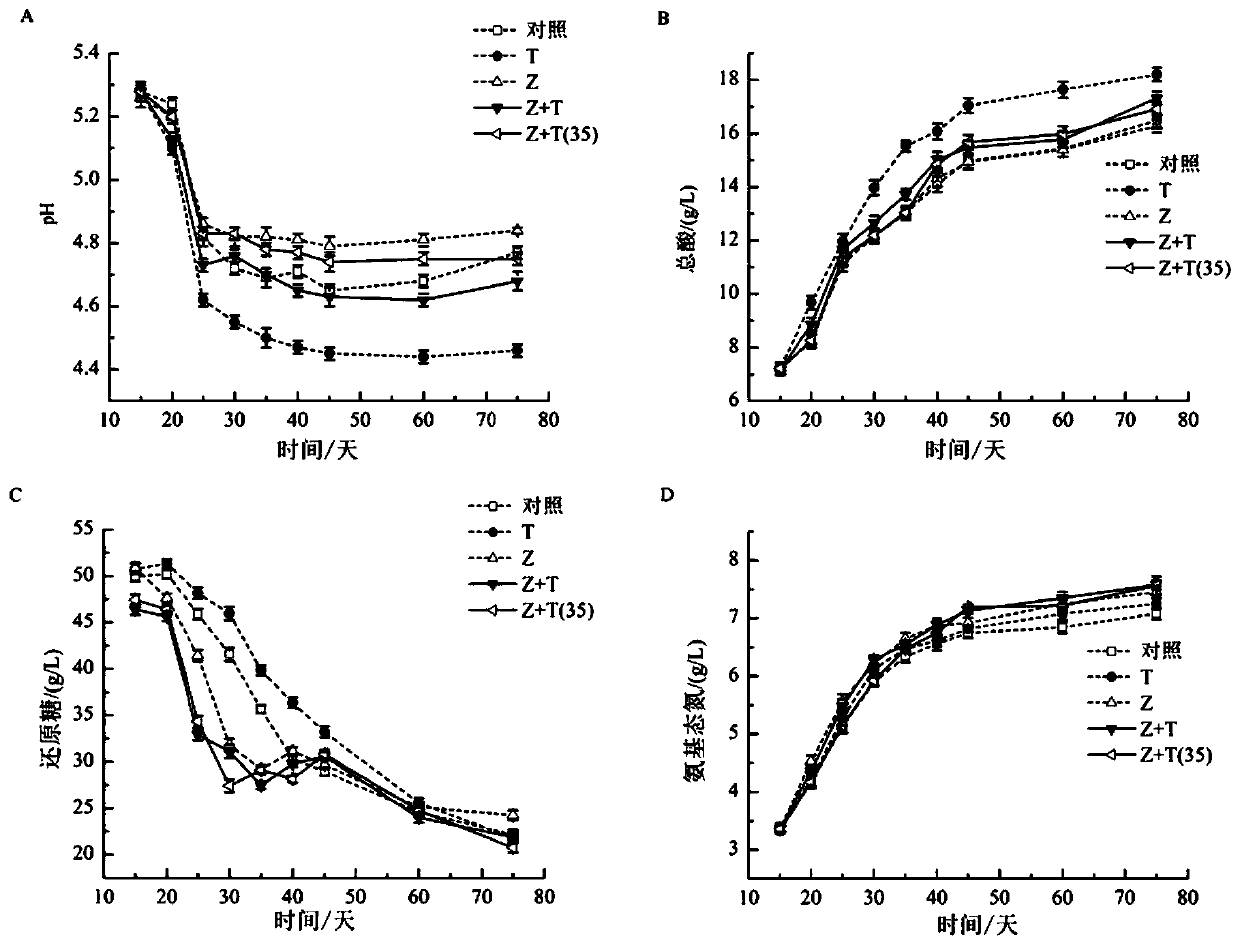

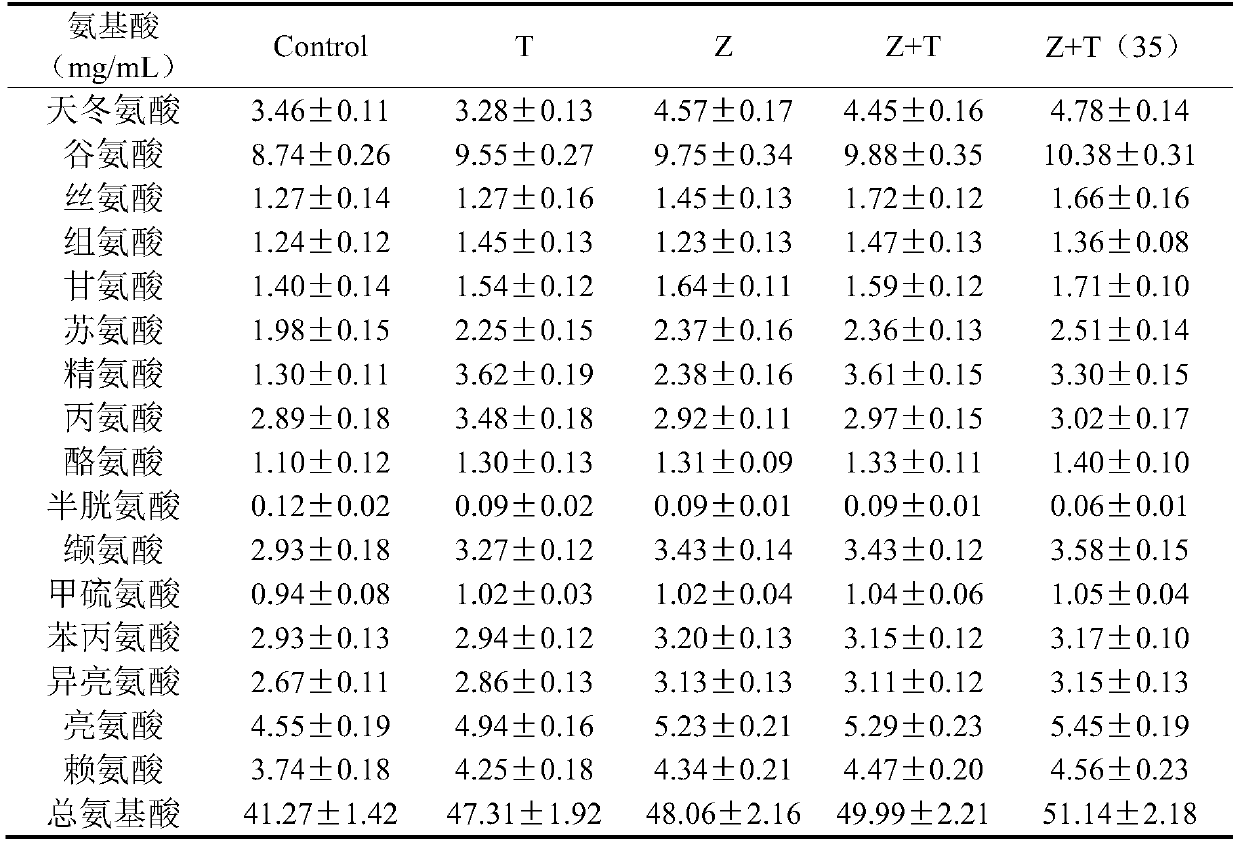

[0043] Example 3: Effects of Strengthening Tetradynococcus halophilus R44 and Zygomyces ruckeri ZQ02 on Physicochemical Indexes of Soy Sauce

[0044] The moromi from Example 1 was sampled on days 15, 20, 25, 30, 35, 40, 45, 60 and 75. Take 100g moromi respectively in a centrifuge tube, 12000r min -1 After centrifugation for 30 min, the supernatant was taken and filtered through a filter membrane with a pore size of 0.22 μm for determination of physical and chemical indicators. The content of amino acid nitrogen in moromi was determined by formaldehyde titration (refer to GB5009.235-2016 for specific steps).

[0045] It has been tested that in this example, the enrichment of Tetradneococcus halophilus R44 and Zygosaccharomyces rouckeri ZQ02 significantly increased the amino acid nitrogen content of moromi. The content of ammonia nitrogen in the moromi added with Zygomyces rouckeri and Tetradococcus halophilus on the 35th day was 7.56g / L, which was 6.8% higher than that of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com