Controller cluster device applied to thermal power plant

A controller cluster, controller technology, applied in the direction of comprehensive factory control, electrical program control, comprehensive factory control, etc., can solve the problems of increasing the workload and cost of operation and maintenance, shorten the time of fault diagnosis and switching, and improve the communication rate , the effect of reducing the load rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

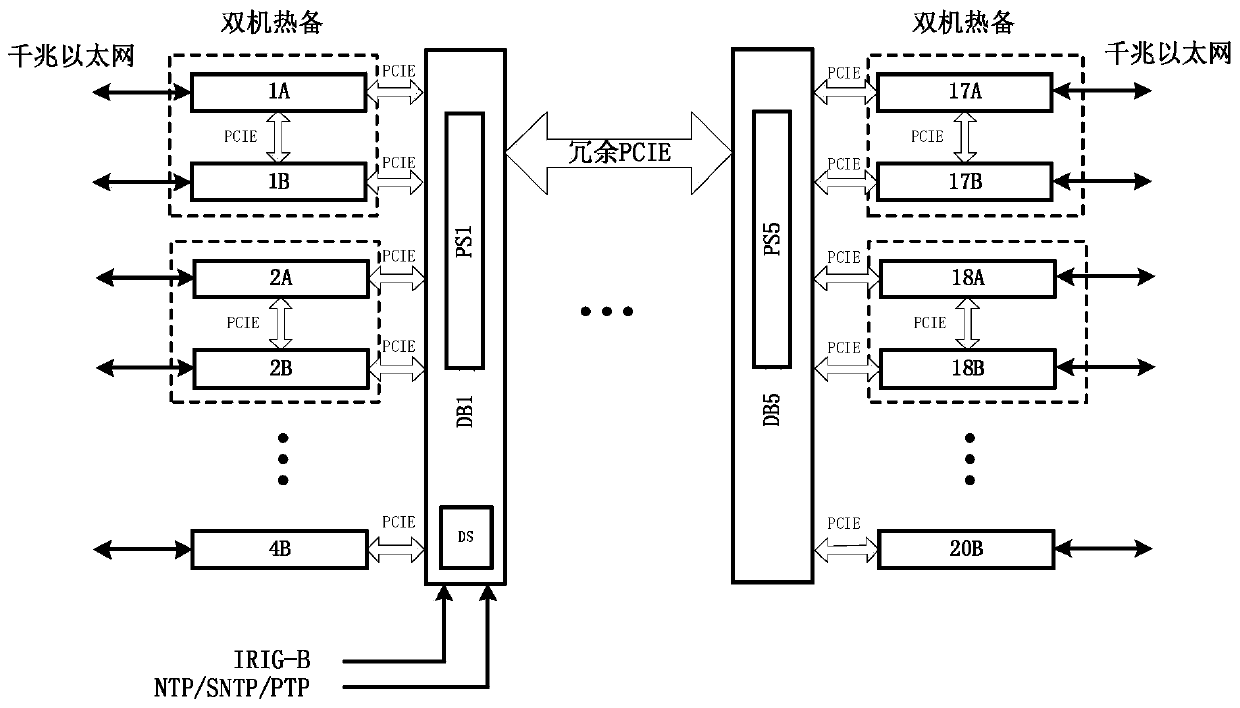

[0022] As shown in the drawings, this embodiment is a controller cluster device applied to a thermal power plant, including the first bottom board DB1 ... the fifth bottom board DB5, a total of 5, each bottom board is evenly distributed with 8 slots, each slot One bit corresponds to one controller, a total of 40 controllers, each controller is connected to the backplane slot through a redundant PCIE bus; the first backplane DB1 is connected to the first controller 1A, the second controller 1B, and the third controller 2A , the fourth controller 2B ... the eighth controller 4B, and so on, the fifth bottom board DB5 is connected to the thirty-third controller 17A, the thirty-fourth controller 17B, the thirty-fifth controller 18A, the thirty-sixth controller Controller 18B...the fortieth controller 20B; the first bottom board DB1 bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com