Clamp suitable for impedance measurement under high-temperature and high-frequency conditions

An impedance measurement, high-frequency technology, applied in the field of impedance measurement fixtures under high temperature and high frequency conditions, can solve the problems of difficult to meet the measurement temperature requirements, difficult to meet the measurement requirements, limited measurement temperature, etc., to improve convenience and durability. High temperature characteristics, the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

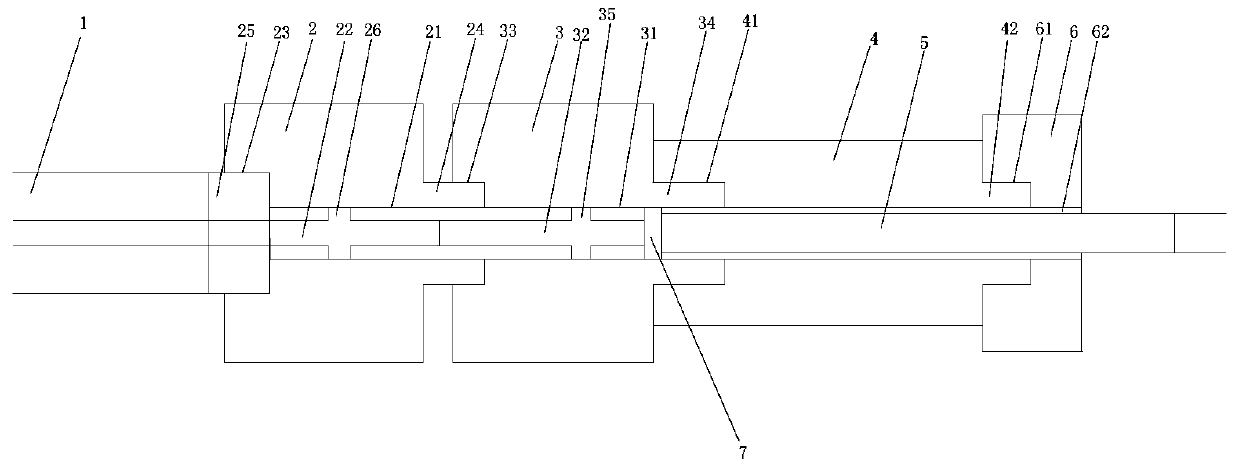

[0030] Such as figure 1 As shown, the fixture provided in this embodiment is suitable for impedance measurement under high temperature and high frequency conditions, including data line 1, connector I2, connector II3, outer tube 4, and inner column 5;

[0031] The joint I2 is provided with a through hole I21 extending in the left and right directions, and a guide post I22 is fixed in the through hole I21, and the guide post I22 is arranged in the axial direction of the through hole I21; the data line 1. The left end is connected to the vector network analyzer, and the right end is inserted into the joint I2 to connect with the guide post I22; the left end of the joint II3 is matched with the right end of the joint I2 and can be connected into one; the joint II3 is set in the left and right directions The through hole II31, the guide post II32 is fixed inside the through hole II31, the guide post II32 is arranged along the axial direction of the through hole II31, and the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com