Supercharger protection control system

A technology of protection control and supercharger, which is applied in the direction of controlling the pressure of lubricant, control temperature of lubricant, pressure lubricant, etc. It can avoid problems such as the increase of the operating temperature of the bearing of the device, so as to prevent damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

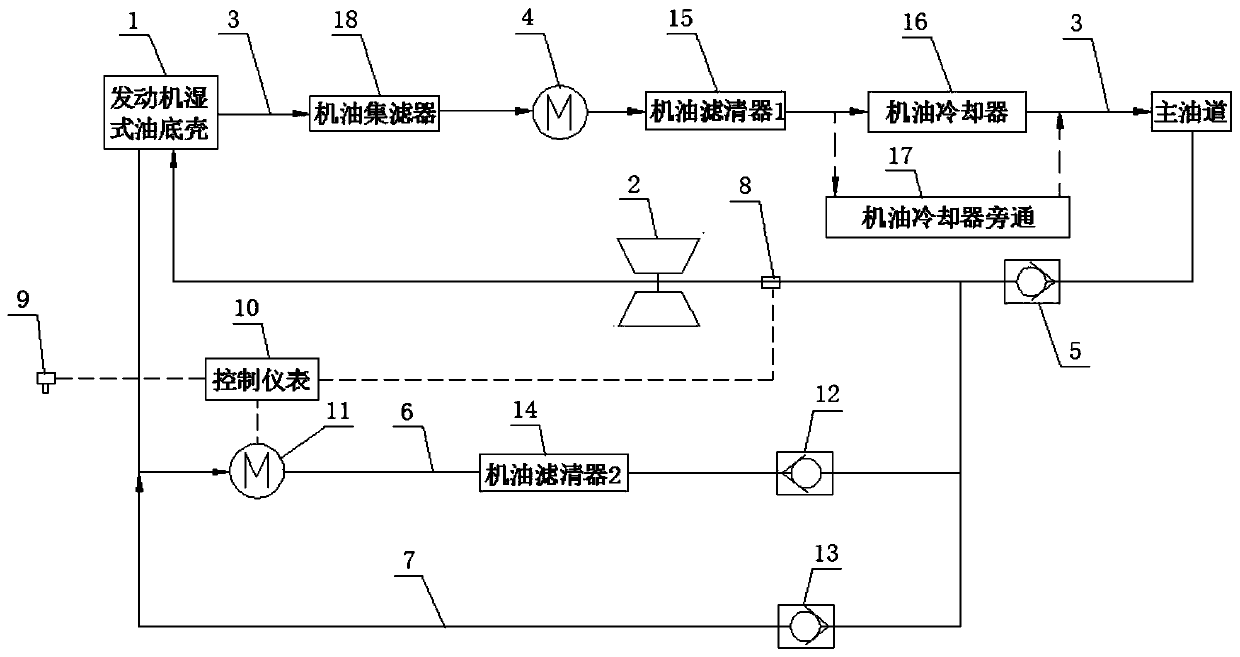

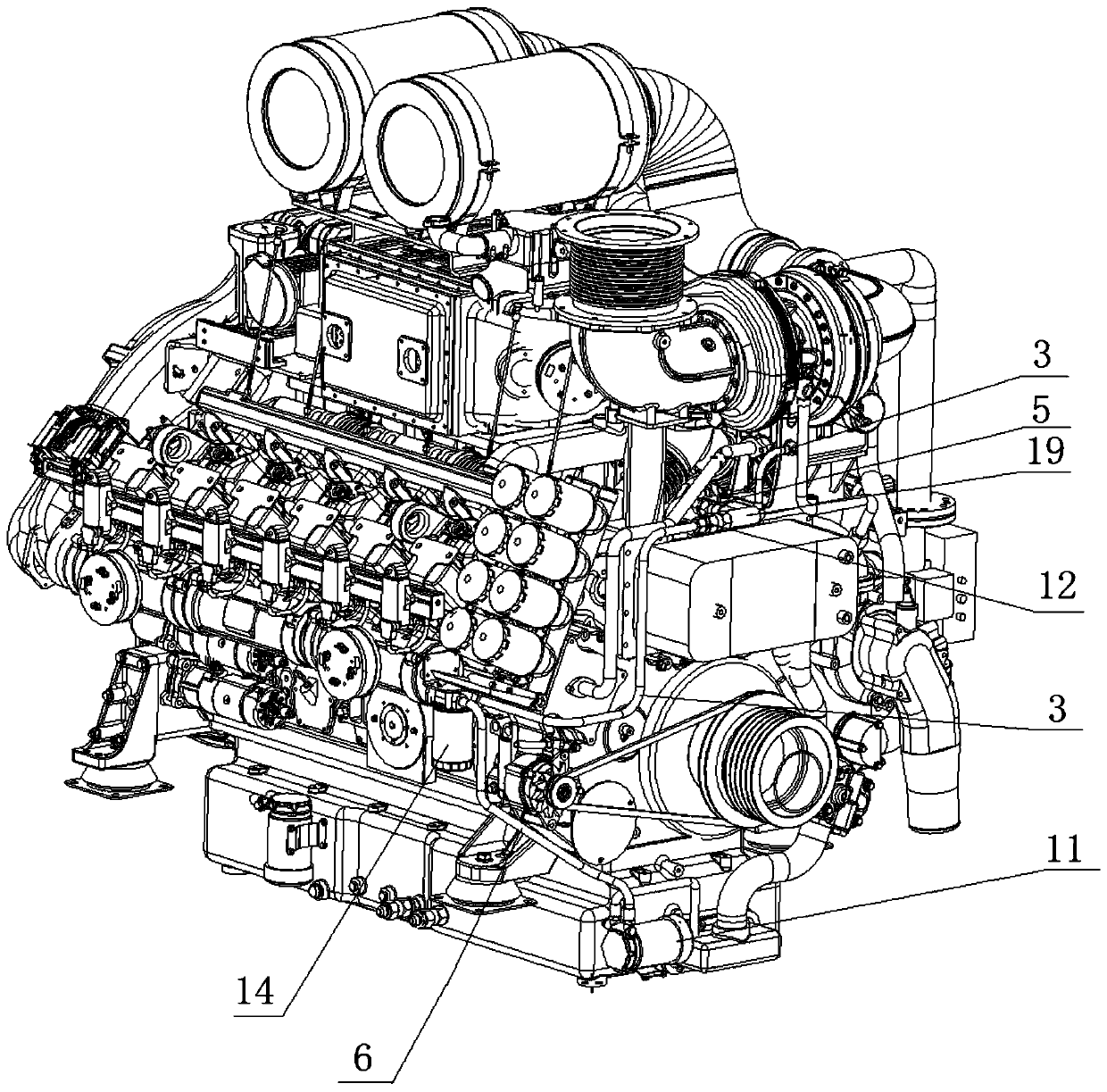

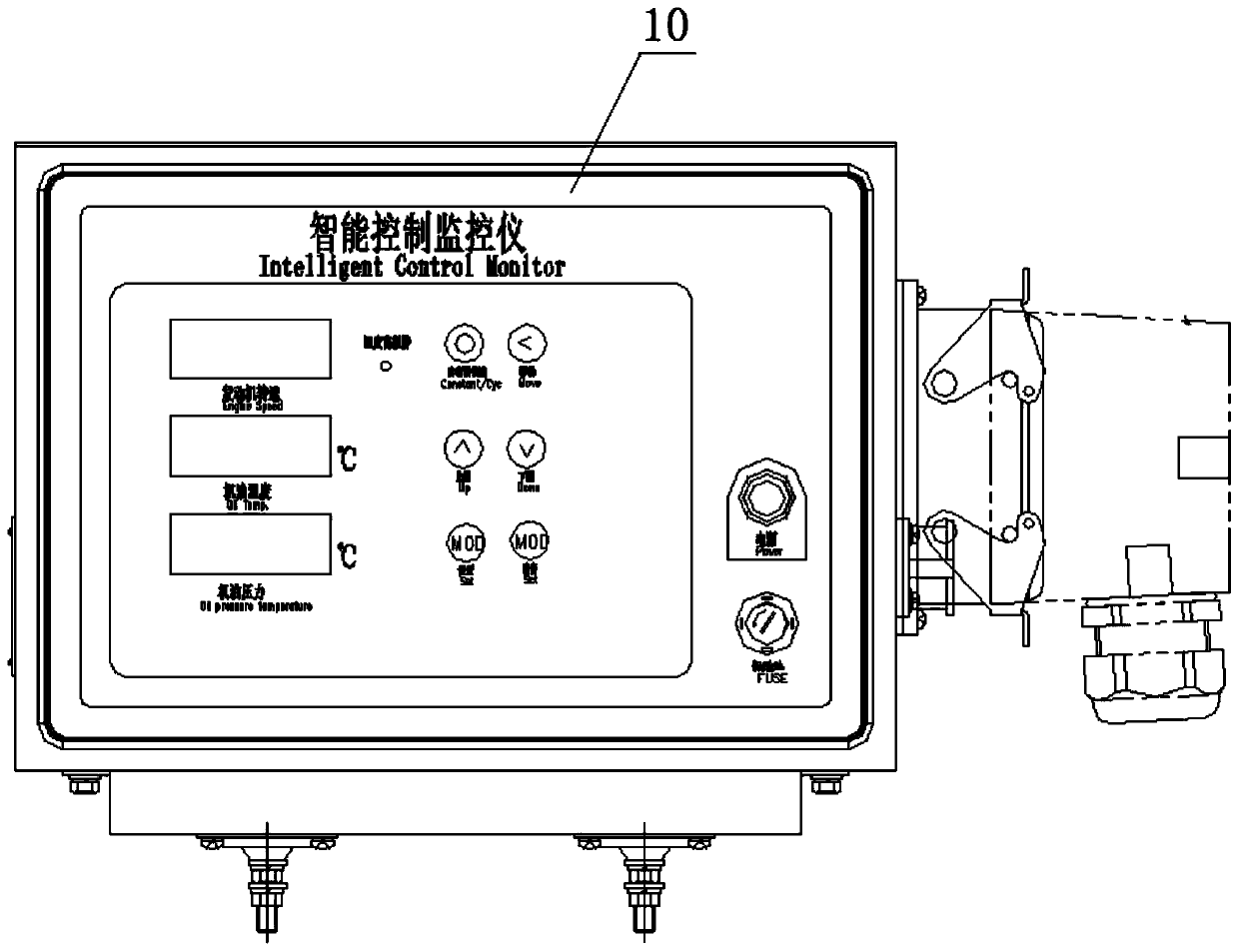

[0024] refer to Figure 1-3 , a supercharger protection control system, including the main oil circuit 3 connecting the engine oil pan 1 with the turbocharger 2, and the main oil circuit 3 from the engine oil pan 1 to the turbocharger 2 is sequentially arranged There is a first oil pump 4 and a first one-way valve 5 . It also includes an auxiliary oil passage 6 connecting the engine oil pan 1 with the turbocharger 2, a protection oil passage 7 connected in parallel with the auxiliary oil passage 6, a pressure sensor 8 for detecting the oil pressure at the input end of the turbocharger 2, A rotational speed sensor 9 and a controller 10 for detecting engine rotational speed, and the auxiliary oil passage 6 are connected with the main oil passage 3 through a three-way valve 19 . A second oil pump 11 and a second check valve 12 are sequentiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com