Method for drawing large-size low-oxygen silicon single crystal by RCZ method

A large-scale, oxygen-silicon technology, applied in the field of large-scale low-oxygen silicon single crystal drawn by RCZ method, can solve the problems of poor stability and reduction of single crystal oxygen content, and achieve fast adjustment speed, product quality improvement, and fast response speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

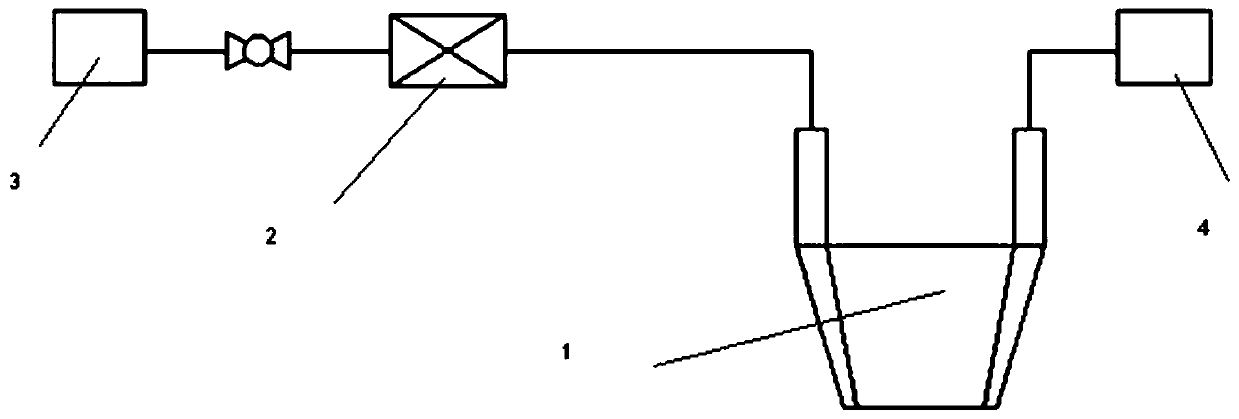

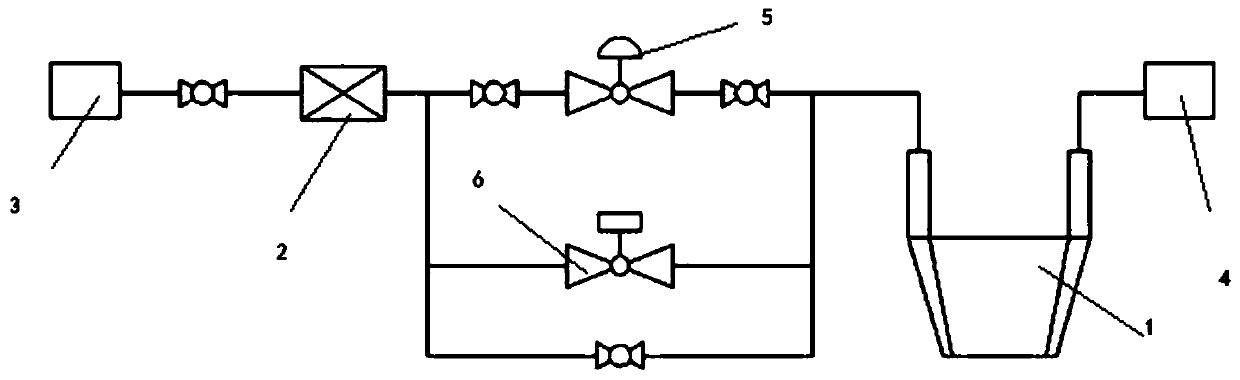

[0029] according to figure 1 with figure 2 According to the structural difference, the original equipment is improved by adding valves and related control chains, and the preparation process is carried out by using the improved structure.

[0030] A method for pulling a large-sized low-oxygen N-type silicon single crystal by RCZ method, including the following steps (performed according to the normal RCZ single crystal pulling method, and the specific position needs to be adjusted, which will be explained below):

[0031] Step 1, dismantle the furnace and clean the furnace;

[0032] Step 2, furnace loading;

[0033] Step 3, vacuumize and detect leaks in the single crystal furnace;

[0034] Step 4, pressure and melting, set the water flow rate of the water cooling screen to 30-280slpm; set the crucible speed to 4-12r / min, the pressure in the furnace to 1000-2500Pa, the flow rate of the inert gas to 10-120slpm, the melting power 30-360KW, and finally get liquid silicon;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com