Film for flexible circuit board and preparation method thereof

A thin-film preparation and thin-film technology, applied in the field of thin-film materials, can solve the problems of insufficient production capacity, high difficulty, and inability to process the cast film, so as to improve the film-forming efficiency, save processing steps and manufacturing costs, and avoid defects in the quality process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

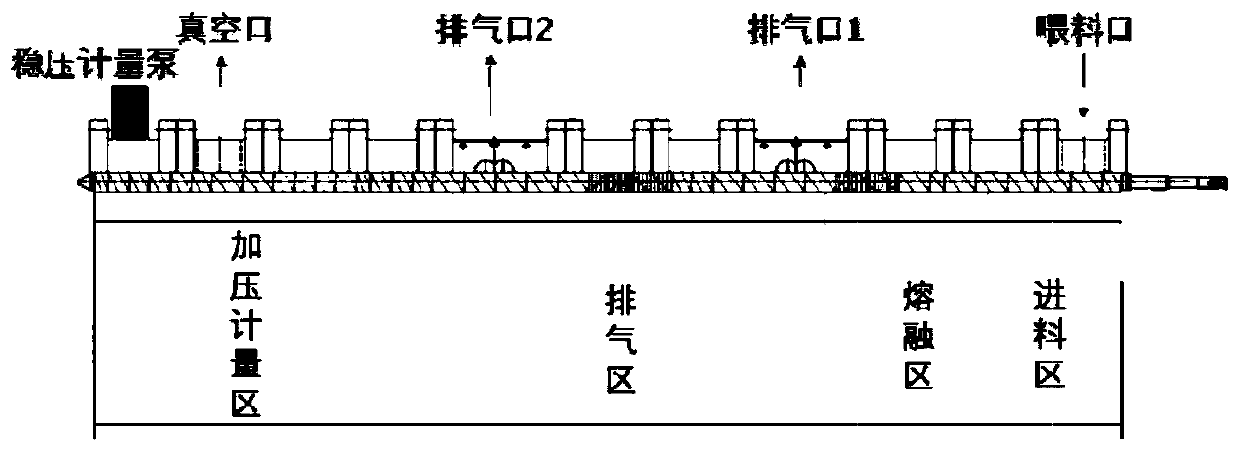

Method used

Image

Examples

Embodiment 1

[0035] Pass through the extruded film production line with the following formula table, set the torque at 90%, and control the melt temperature at 340°C to obtain polyphenylene ether resin film A (the present invention) and resin film B (commonly used) with a width of 200 mm and a thickness of 100 μm. Modified polyphenylene ether resin film)

[0036] Resin film A component is:

[0037] Chemical Name Purchasing Specifications weight component Polyphenylene ether Bluestar LXR040 70% Silicone resin Nanjing Peiwei MS0825 10% Inorganic filler Chemours Titanium Dioxide R-101 20%

[0038] Resin film component B is:

[0039] Chemical Name Purchasing Specifications weight component Polyphenylene ether Bluestar LXR040 70% polystyrene Ningbo Taihua GP535N 10% Inorganic filler Chemours Titanium Dioxide R-101 20%

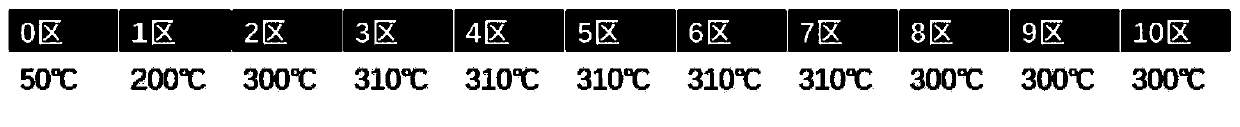

[0040] Respectively take 5 samples of resin film A and resin film B to carry out physical p...

Embodiment 2

[0048] Use the following formula table to set the torque 90% by the extruded film production line, and when the temperature of the melt is controlled at 340° C., the polyphenylene ether resin film C (the present invention) and the resin film D (commonly improved) that the width is 200 mm and the thickness is 100 μm are obtained. permanent polyphenylene ether resin film)

[0049] Resin film C component:

[0050] Chemical Name Purchasing Specifications weight component Polyphenylene ether Bluestar LXR040 94.9% Silicone resin Nanjing Peiwei MS0825 2.1% Inorganic phosphorus compound Zhejiang Wansheng PX220 3%

[0051] Resin film D component:

[0052]

[0053]

[0054] The flame retardancy test of UL94 soft film plastics (film thickness <0.25mm) was carried out on resin film C and resin film D. According to ASTM D4804-03, the results are as follows:

[0055]

[0056] It can be seen that only a small amount of inorganic phosphorus...

Embodiment 3

[0059] Use the following formula table to set the torque 90% by extruding the film production line, and control the melt temperature at 340 ° C to obtain a polyphenylene ether resin film E (the present invention) with a width of 200 mm and a thickness of 100 μm

[0060] Resin film E component:

[0061]

[0062] It can be seen that as the content of titanium dioxide is different, films with different dielectric constants can be obtained to meet the transmission of signals of different frequencies, and the dielectric loss of the polyphenylene ether resin film of the present invention does not change for signals of different frequencies, and still maintains high efficiency. transmission effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com