Molecular sieve pore-expanding method

A treatment method and molecular sieve technology, applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as unfavorable catalytic activity, and achieve the effect of increasing the size of micropores and increasing the volume of micropores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

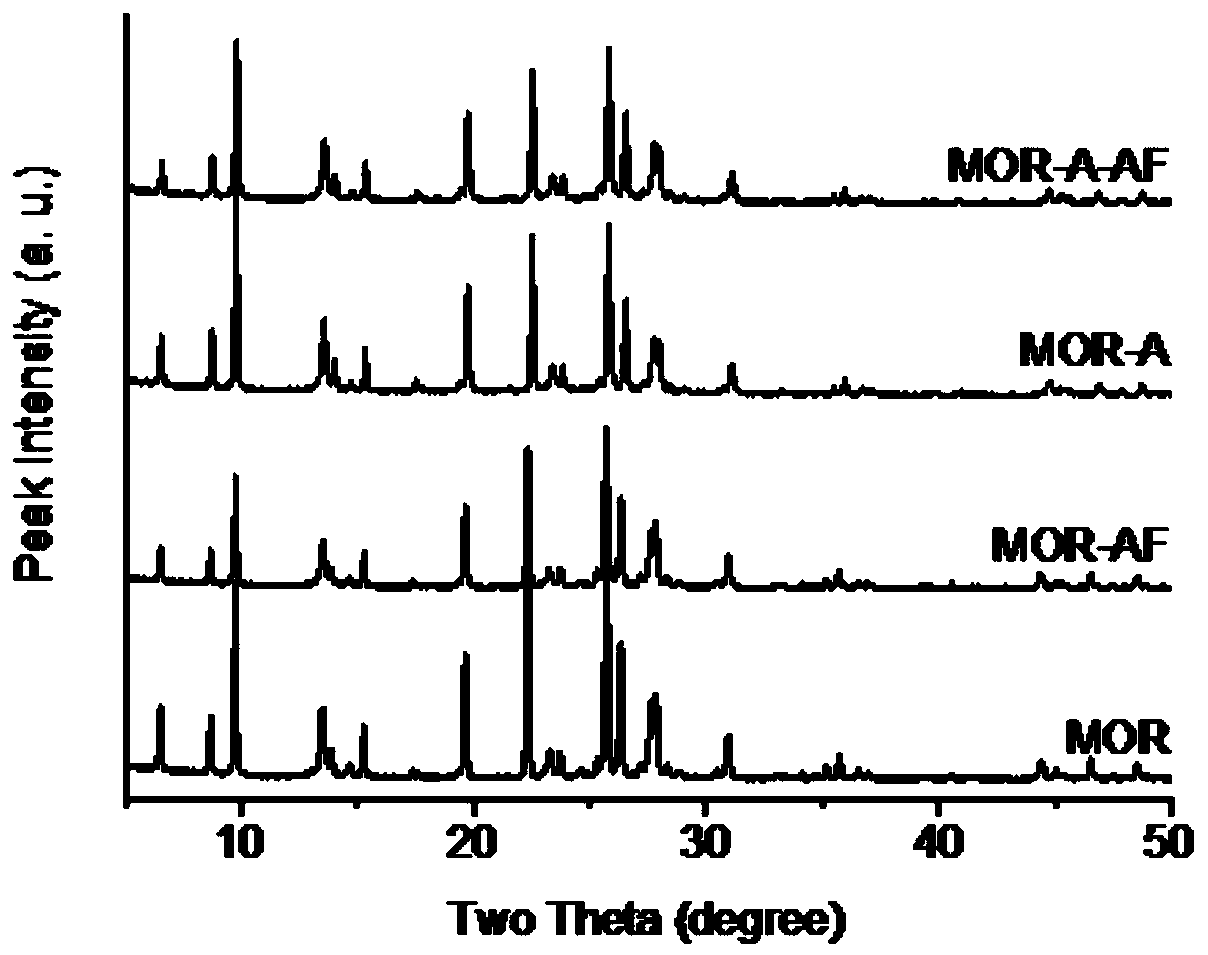

[0023] Put 63g of oxalic acid dihydrate into 750g of water, and after preparing a solution, disperse 5g of the initial ammonium-type mordenite molecular sieve (MOR-P) in it, treat it at 90°C for 46h, and then filter it. After drying for 12 hours, the obtained sample was designated as MOR-A.

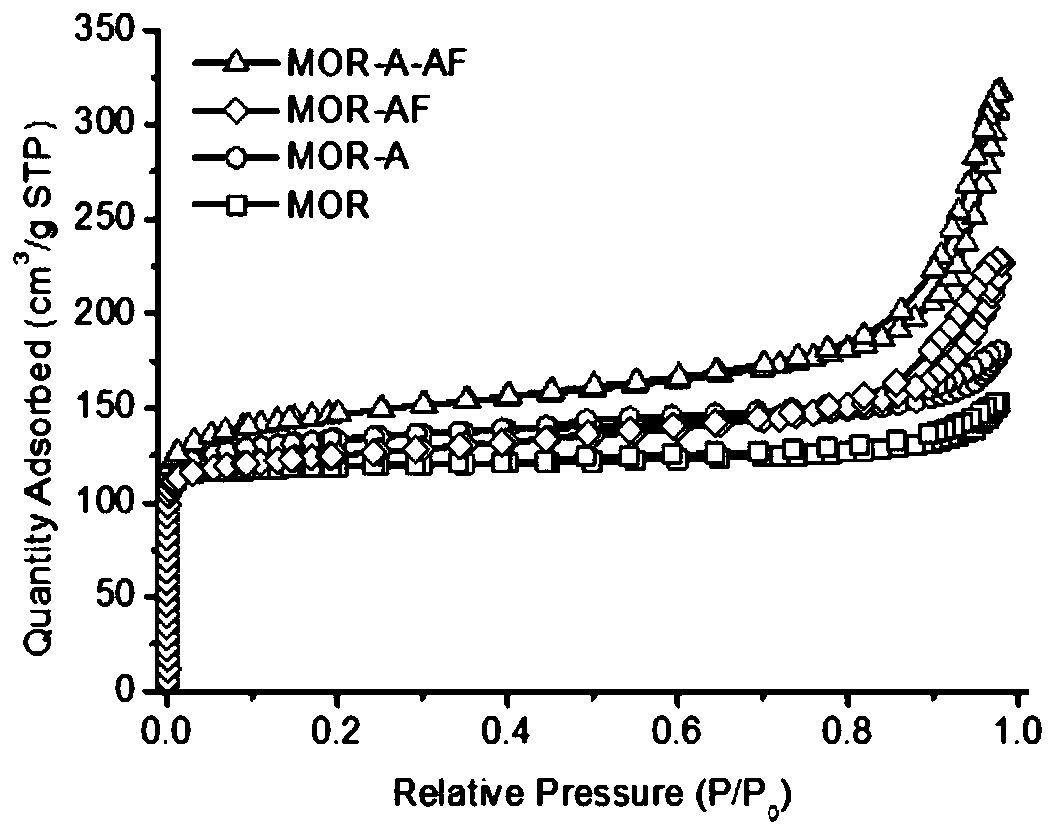

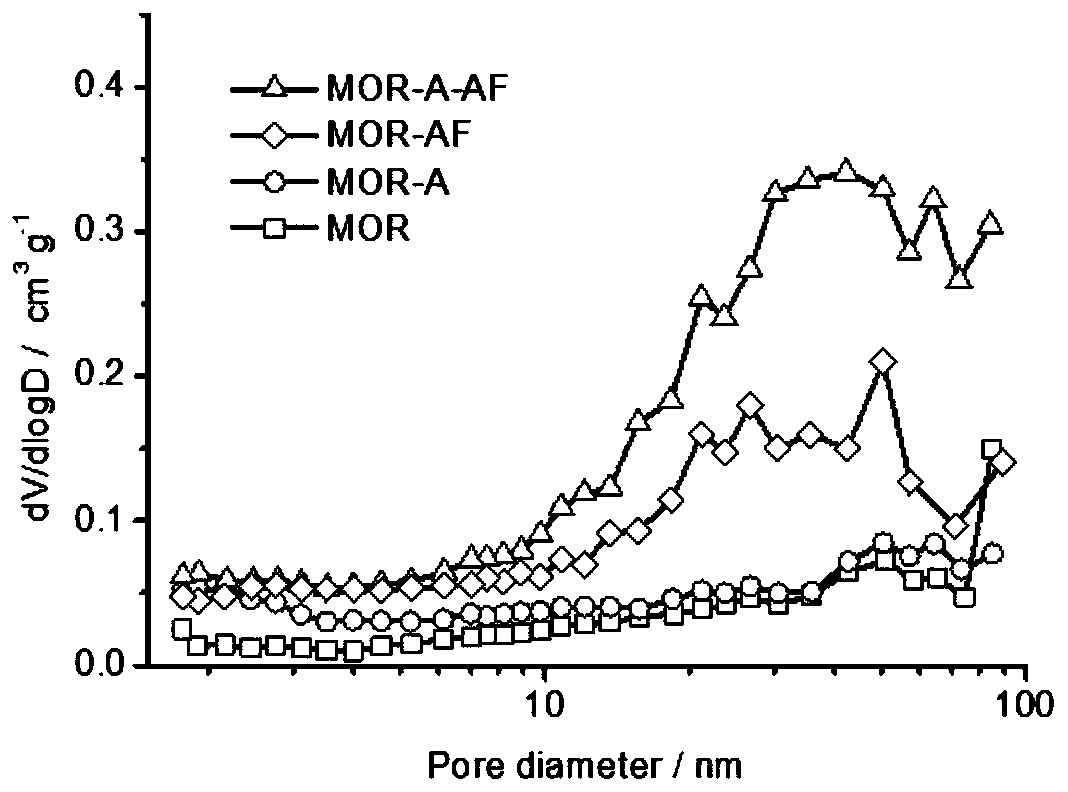

[0024] Disperse 10 g of the obtained acid-treated sample MOR-A in 300 g of a 30% ammonium fluoride solution, heat the above mixture to 50 ° C, and treat it under ultrasonic conditions for 1 h, then filter, wash and dry the mixture, and the obtained sample is recorded as Make MOR-A-AF. The micropore volume of the final product molecular sieve is changed from 0.154cm 3 / g increased to 0.163cm 3 / g, and a certain amount of secondary pores with a size slightly larger than the intrinsic microporous structure are produced.

Embodiment 2

[0026] Disperse 50 g of Y-type molecular sieve molecular sieves in 500 g of water, and add 50 g of ammonium sulfate thereinto, and stir to make them evenly mixed. Heat the above-mentioned molecular sieve slurry to 85°C, and add sulfuric acid with a concentration of 2 mol / l dropwise to it until the pH value of the system reaches 1.8. After maintaining for 30 minutes, filter the above-mentioned mixture, wash the filter cake fully and dry it. The obtained sample is recorded as USY -A.

[0027] 10 g of the sample (Y-A) obtained by the above acid treatment was dispersed in 100 g of ammonium fluoride solutions with mass fractions of 10% and 20%, respectively, and treated for 10 min at 0°C in the presence of ultrasound. Then filter, wash the filter cake well, and dry at 100°C for 12h. The resulting samples were designated Y-A-AF1, Y-A-AF2 and Y-A-AF3, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com