A processing machine and processing method for the rear wind shell cover of pump body accessories

A processing method and a bellows cover technology are applied in the processing machinery and processing fields of the rear bellows cover of the pump body, which can solve the problems of low processing efficiency, difficulty in controlling the processing accuracy, etc. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

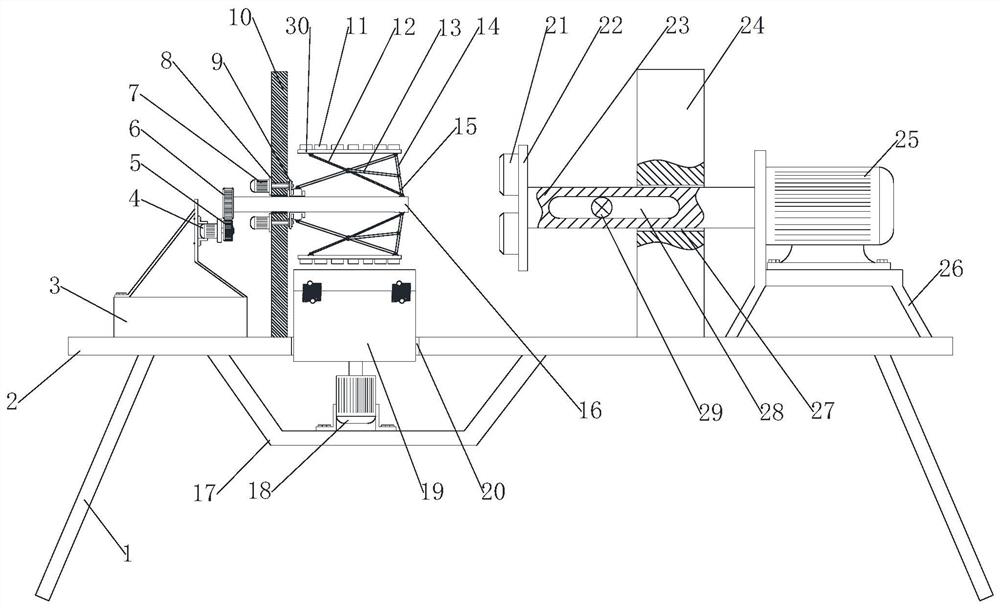

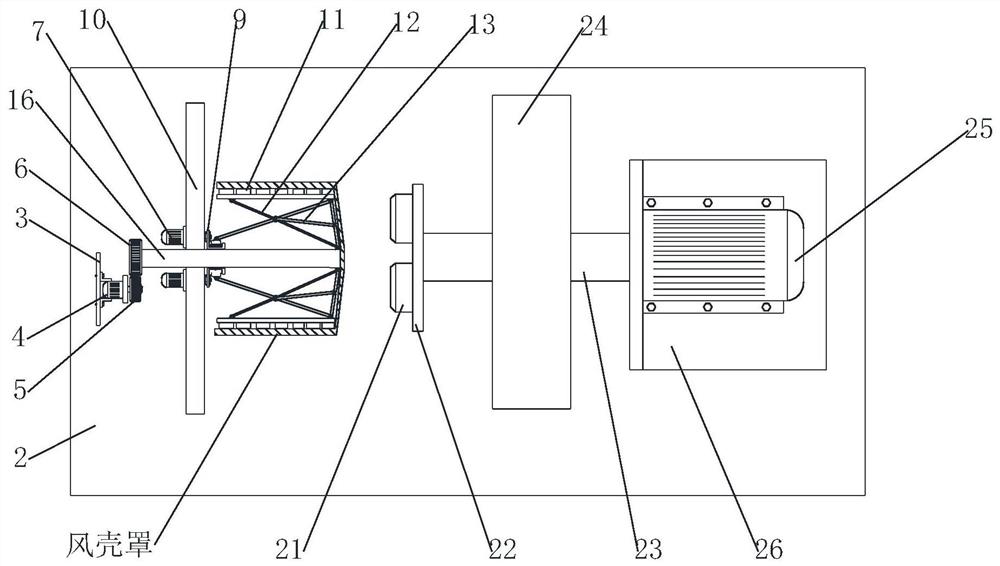

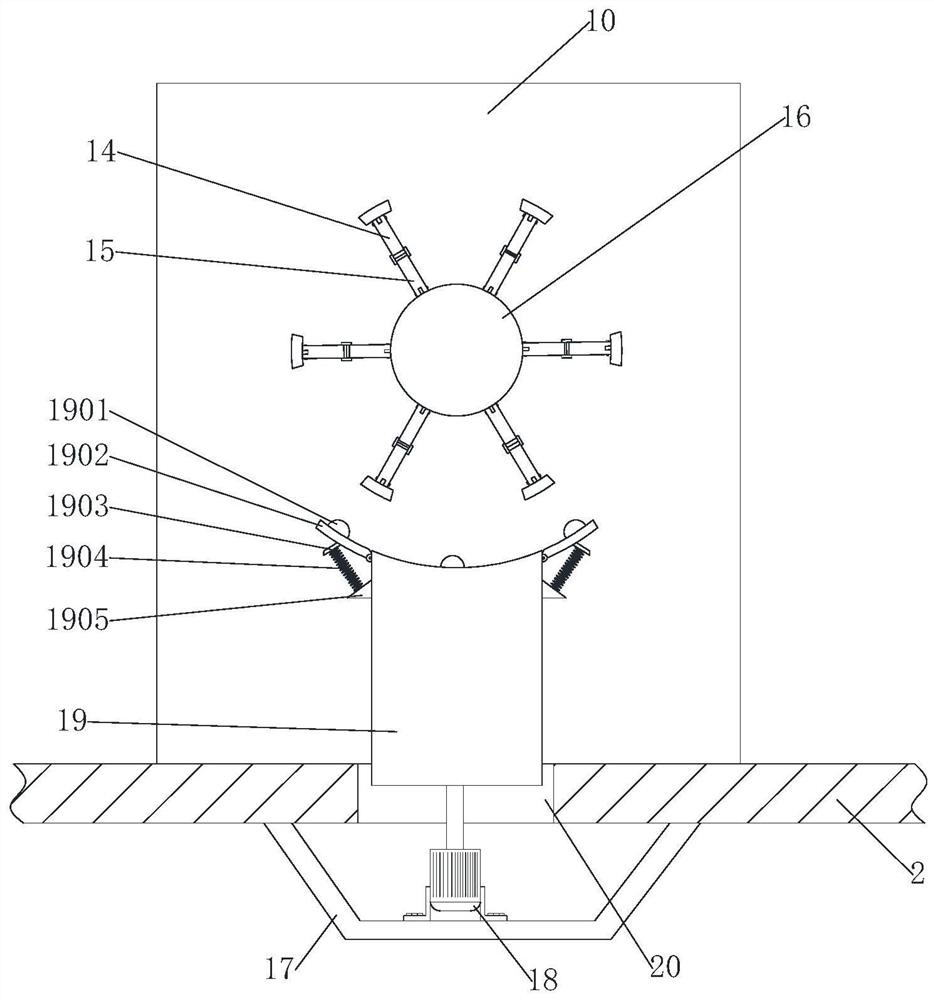

[0040] see Figure 1-7 , which is a schematic diagram of the overall structure of a processing machine for the rear air casing of pump body accessories, a processing machine for processing the rear air casing of pump body accessories, including a horizontally fixed bottom support plate 2, and the bottom of the bottom support plate 2 is provided with a support Supported by legs 1, the top of the bottom support plate 2 is provided with a support rib 10 close to the left side, and the support rib 10 is upright fixed on the top of the bottom support plate 2, and the top of the bottom support plate 2 is provided with an upright bottom plate near the right side. The second support rib 24 at the top of the support plate 2;

[0041] There is a through bearing hole in the middle of the supporting rib 10, and a transmission shaft 16 is installed in the bearing hole of the supporting rib 10 through a rolling bearing. Gear tooth meshing transmission, the first gear 5 is fixedly installed...

Embodiment 2

[0058] see Figure 1-8 , which is a process flow diagram of a method for processing the rear air casing of pump body accessories. This embodiment has similarities with the above-mentioned embodiment 1, and the similarities will not be described in this embodiment. The specific differences are:

[0059] A method for processing a rear air casing of a pump body accessory, the method for processing a rear air casing of a pump body accessory mainly includes the following steps:

[0060] S1. Wind shell installation: install the wind shell to be processed on the outer wall of the transmission shaft 16, push the diamond frame 12 to unfold through the pneumatic cylinder 7, and internally clamp and fix the inner wall of the wind shell;

[0061] S2, end face blanking: carry out blanking processing on the air shell cover installed and fixed in step S1, through the hydraulic cylinder 25; push the punching head 21 to move towards the end face of the air shell cover, and cut and shape the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com