Self-lubricating composite filler for intelligent dressing and preparation method thereof

A composite filler and self-lubricating technology, used in pharmaceutical formulations, pharmaceutical science, drug delivery, etc., can solve the problems of poor conductivity, short service life, and poor durability of dressings, prevent slippage, improve wear resistance, and increase strength. and durability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

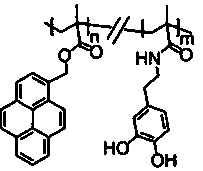

[0033] A kind of self-lubricating composite filler for intelligent dressing provided in this embodiment, comprises the raw material of following mass percent composition: 21% of hydroxyapatite; 5% of fluorinated graphene; 42% of calcium carbonate; 30% of conductive polymer; Agent 2%. Wherein the hydroxyapatite is nanorod-shaped, with a diameter of 10-15 nm and an aspect ratio of 10-13. Wherein the calcium carbonate is spherical calcium carbonate with a particle size of 40-50 μm. Wherein the molecular structural formula of the conductive polymer is:

[0034]

[0035] Wherein the auxiliary agent is a mixed auxiliary agent formed by transglutaminase (TG) and polyphenol oxidase (PPO).

[0036] The preparation method of a kind of self-lubricating composite filler for intelligent dressing provided by the present invention comprises the following steps: (1) preparation of grade ingredients: adding hydroxyapatite and calcium carbonate to the V-type mixer according to the mass rat...

Embodiment 2

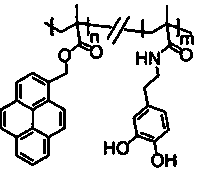

[0038] A kind of self-lubricating composite filler for intelligent dressing provided in this embodiment, comprises the raw material of following mass percent composition: 21% of hydroxyapatite; 5% of fluorinated graphene; 42% of calcium carbonate; 30% of conductive polymer; Agent 2%. Wherein the hydroxyapatite is in the shape of nanorods with a diameter of 12-15nm and an aspect ratio of 12-15. Wherein the calcium carbonate is spherical calcium carbonate with a particle size of 40-50 μm. Wherein the molecular structural formula of the conductive polymer is:

[0039]

[0040] Wherein the auxiliary agent is a mixed auxiliary agent formed by glutaraldehyde and polyphenol oxidase (PPO).

[0041] The preparation method of a kind of self-lubricating composite filler for intelligent dressing provided by the present invention comprises the following steps: (1) preparation of grade ingredients: adding hydroxyapatite and calcium carbonate to the V-type mixer according to the mass ra...

Embodiment 3

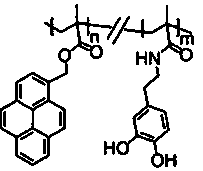

[0043] A kind of self-lubricating composite filler for intelligent dressing provided in this embodiment, comprises the raw material of following mass percent composition: 21% of hydroxyapatite; 5% of fluorinated graphene; 42% of calcium carbonate; 30% of conductive polymer; Agent 2%. Wherein the hydroxyapatite is nanorod-shaped, with a diameter of 10-15nm and an aspect ratio of 12-14. Wherein the calcium carbonate is spherical calcium carbonate with a particle size of 40-45 μm. Wherein the molecular structural formula of the conductive polymer is:

[0044]

[0045] Wherein the auxiliary agent is a mixed auxiliary agent formed by transglutaminase (TG) and glutaraldehyde.

[0046] The preparation method of a kind of self-lubricating composite filler for intelligent dressing provided by the present invention comprises the following steps: (1) preparation of grade ingredients: adding hydroxyapatite and calcium carbonate to the V-type mixer according to the mass ratio, Prelim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com