Bracket for vertical steel reel packaging

A technology for packaging and steel coils, which is applied in the directions of packaging, transportation, packaging, and external frames. It can solve the problems that the ends are easy to touch the surface of the steel coil, the surface of the steel coil is damaged, and the size cannot be adjusted, so as to achieve simple structure and convenience. Manufacture, increase strength and durability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

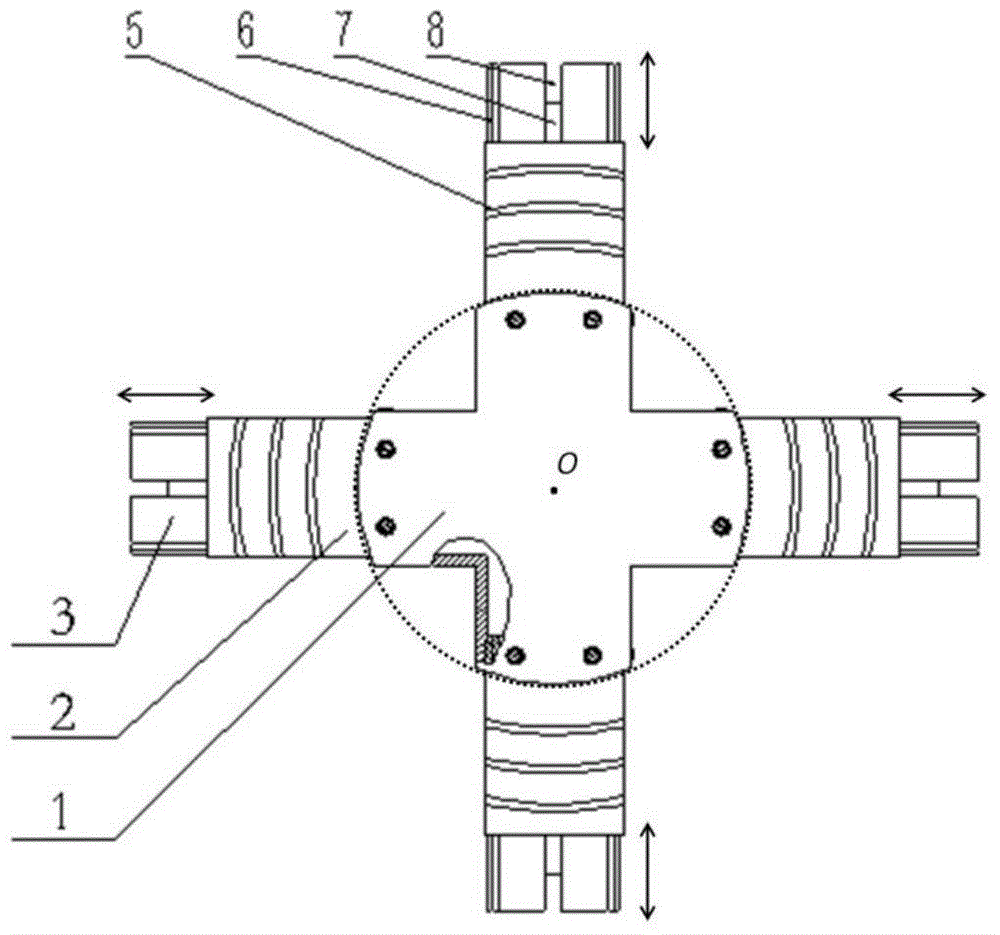

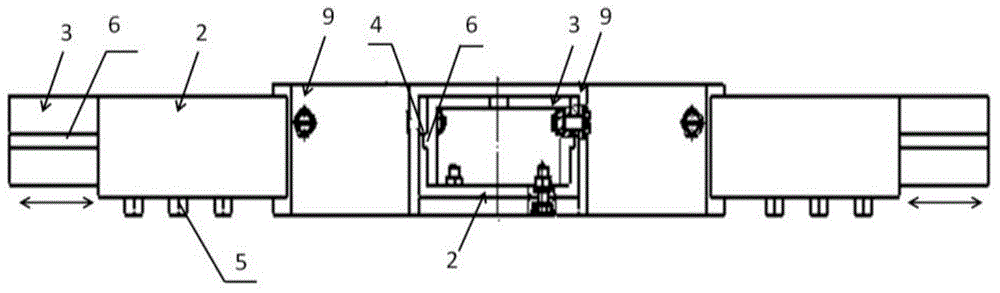

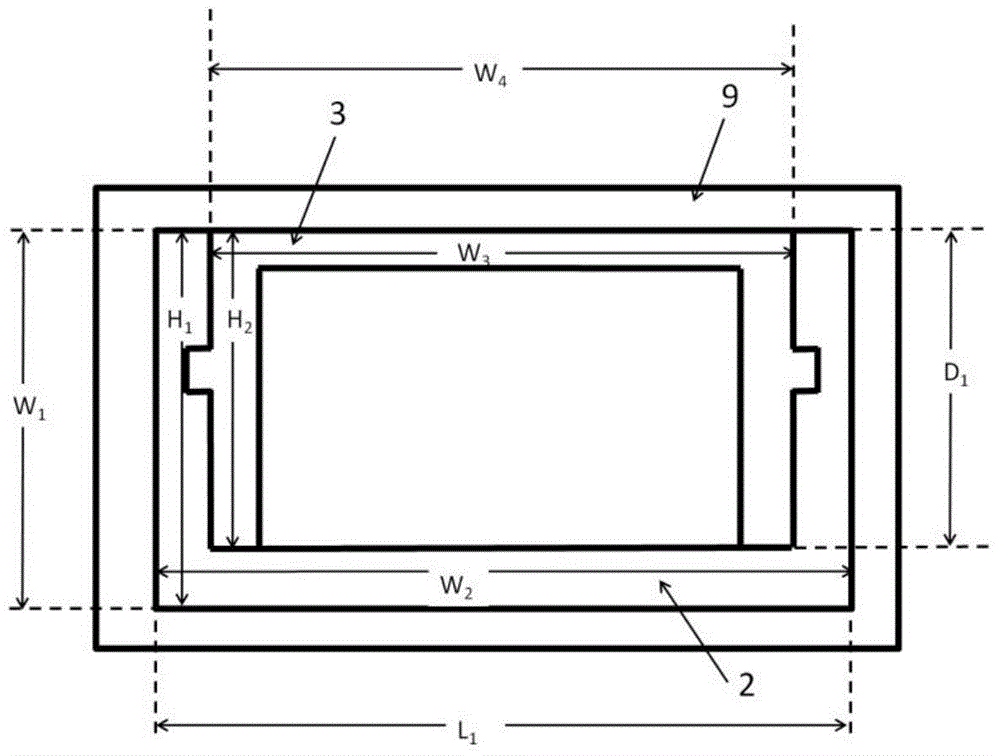

[0025] This embodiment provides a size-adjustable vertical steel coil packaging bracket, which is suitable for the occasion of packaging multiple steel coils with different outer diameters. The "upper", "lower" and "bottom" mentioned in this embodiment only mean figure 2 The relative position in , not limited to the position in real space. Such as figure 1 and figure 2 As shown, the bracket 16 for vertical steel coil packaging in this embodiment is made of steel material, and includes connectors 1 , four outer slider beams 2 and four inner slider beams 3 .

[0026] The connecting piece 1 is located in the center of the bracket 16 for vertical steel coil packaging, and has two pairs of hollow arms 9 . Each pair of arm portions 9 is symmetrical about the center of mass O of the connector 1 , so that the four arm portions 9 are arranged in a cross shape. The outer edges of the arms 9 are circular arcs, and the curvatures of the outer edges of each arm 9 are equal. Therefore...

Embodiment 2

[0033] In the first embodiment, the boss provided on the bottom of the outer slider beam extends along the width direction of the outer slider beam, however, the boss can also extend along other directions. Such as Figure 4 As shown, the bracket for vertical steel coil packaging includes connectors 10 , four outer slider beams 11 and four inner slider beams 12 . The included angle α formed by the extension direction of the plurality of bosses 13 at the bottom of the outer slider beam 11 and the tangential direction of the outer edge of the arm portion 14 of the connector 10 is 45 degrees. The distance between two adjacent bosses 13 is equal and greater than the width of the sling, which facilitates the passing of the sling during lifting, and then facilitates lifting. Similarly, it is also convenient for forklift transportation. Other structures of the bracket for vertical steel coil packaging in this embodiment are basically the same as those of the bracket for vertical ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com