Preparation method of super-strong durable material

A durable and super-strong technology, applied in the field of cement-based materials, can solve problems without precedent and data support, and achieve the effects of improving production efficiency, reducing CO2 emissions, and improving strength and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

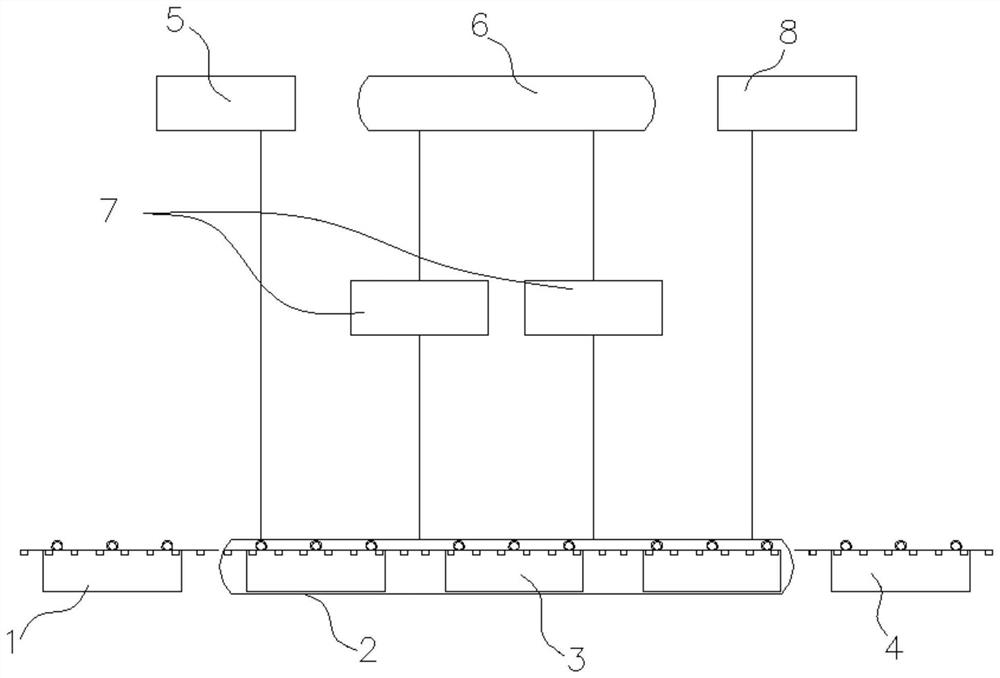

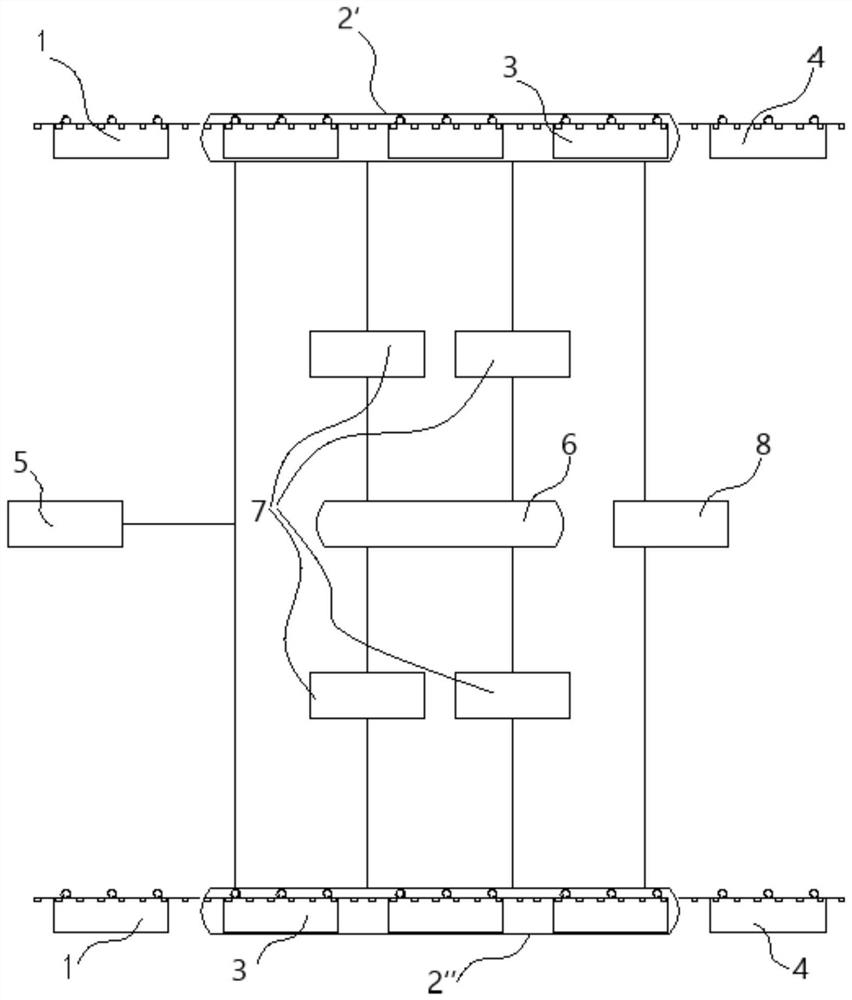

Image

Examples

Embodiment 1

[0052] A method for preparing a super durable material, comprising:

[0053] In terms of mass percentage, the following raw materials are weighed: 49% ground cement, 35% graded fine sand, 15% superfine ash, and an admixture whose solid content accounts for 1% of the total amount of raw materials; the ground cement, graded Mix with fine sand, superfine ash and admixture, add water and stir to get mortar;

[0054] Among them, the ground cement is obtained by grinding pure clinker PO524 cement, and the specific surface area of the ground cement is 680m 2 / kg, fineness 80μm sieve 6%;

[0055] The graded fine sand is mixed with gold ore tailings and iron ore tailings in half and sieved, and then mixed according to 1:1:1 of coarse, medium and fine, with a crushing value of 5%, a fineness of 0.1-0.6mm, and an apparent density of Greater than 2700kg / m 3 , bulk density greater than 1400kg / m 3 , the mud content is less than 0.1%;

[0056] Ultrafine ash is made by mixing silica fu...

Embodiment 2

[0074] A method for preparing a super-durable material, the process of which is basically the same as that of Example 1, the difference being that, in terms of mass percentage, the following raw materials are weighed: 49% ground cement, 27% graded fine sand, 8% steel Fiber, 15% superfine ash, and an admixture with a solid content of 1% of the total raw material.

[0075] The test block is molded by semi-dry method. The strength of the test block is >850MPa in 3 days, and the flexural resistance is >150MPa. Method) RCM-Ⅴ, electric flux method Q-Ⅴ, anti-carbonization performance level T-Ⅴ.

Embodiment 3

[0077] A method for preparing a super-durable material, the process of which is basically the same as that of Example 2, the difference being that, in terms of mass percentage, the following raw materials are weighed: 45% finely ground cement, 8% metakaolin, 27% graded Fine sand, 8% steel fiber, 11% superfine ash, and an admixture with a solid content of 1% of the total raw material.

[0078] The test block is molded by semi-dry method. The strength of the test block after 3 days is >1050MPa, and the flexural strength is >180MPa. Method) RCM-Ⅴ, electric flux method Q-Ⅴ, anti-carbonization performance level T-Ⅴ.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com