Counter electromotive force detection circuit of brushless direct current motor and range hood applying counter electromotive force detection circuit

A technology of brushed DC motor and counter electromotive force, which is applied in the direction of electronic commutation motor control, application, and oil fume removal, etc. It can solve the problems of high cost, affecting product function expansion, and less resources, and achieves fast hardware processing speed and improved processing real-time The effect of simplification and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

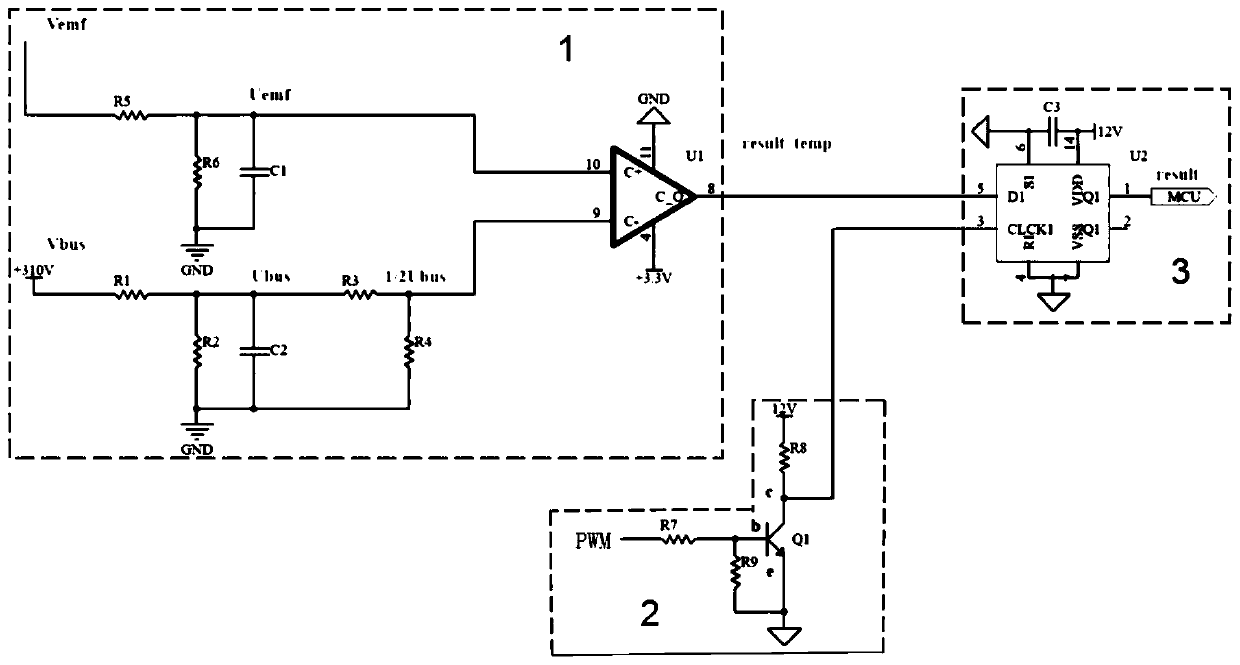

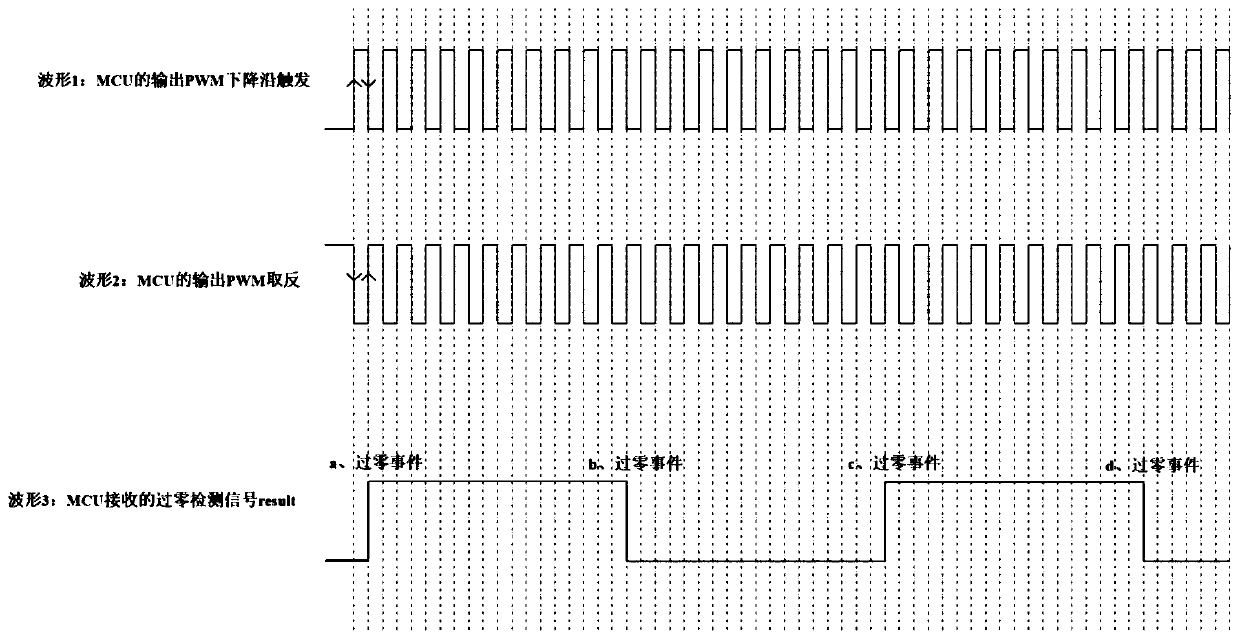

[0023] Embodiment 1 of the present invention provides a back electromotive force detection circuit of a brushless DC motor, such as figure 1 As shown, it includes an input comparison module 1, a conversion module 2 and a latch output module 3. The input comparison module 1 compares the bus voltage and the counter electromotive force, and sends the comparison result to the latch output module 3. The latch After receiving the trigger signal from the conversion module 2, the storage and output module 3 latches the comparison result of the input comparison module 1 and finally outputs it.

[0024] In this way, using the above structure, the input comparison module 1 is used to compare the input bus voltage Vbus and the counter electromotive force Vemf after processing, and output the intermediate result result_temp of Uemf≥1 / 2Ubus or Uemf≤1 / 2Ubus to the latch output module 3, After receiving the trigger signal from the conversion module 2, the latch output module 3 latches and out...

Embodiment 2

[0045] Embodiment 2 of the present invention provides a range hood, which includes the counter electromotive force detection circuit of the brushless DC motor, the range hood body and the motor, the range hood body is equipped with a motor, and the motor is equipped with Back EMF detection circuit for brushed DC motor.

[0046] In this way, the counter electromotive force detection circuit of the brushless DC motor of the present invention is arranged in the motor in the main body of the range hood, and the DC variable frequency range hood using the counter electromotive force detection circuit of the brushless DC motor of the present invention can realize real-time control of the motor. Both performance and accuracy have been effectively improved.

[0047] The invention replaces the software algorithm with the hardware circuit detection method, releases the internal resources of the MCU processor, and provides MCU space resources for the expansion of functions other than moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com